Home > Product > Gas turbine system > MDD093C-N-020-N2L-130GA00 servo motor

MDD093C-N-020-N2L-130GA00 servo motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MDD093C-N-020-N2L-130GA00

- Get the latest price:Click to consult

MDD093C-N-020-N2L-130GA00 servo motor

Product Details Introduction

Installation of Indramat MDD093C-N-020-N2L-130GA00 requires the use of a 130mm centering diameter bracket with a fixed torque of 150-180N · cm, suitable for any installation orientation without vibration displacement.

Before wiring, confirm that the power supply voltage matches the rated specifications of MDD093C-N-020-N2L-130GA00 to avoid damage to the winding and encoder built-in circuit caused by fluctuations.

This model is compatible with Indramat digital drivers, and the encoder stores motor specific data. Drive matching needs to be completed through system parameters to achieve fast startup.

The encoder signal line is separately wired with a dedicated shielded cable, and the right connector is locked in place to reduce electromagnetic interference and ensure position feedback accuracy.

Regularly clean the MDD093C-N-020-N2L-130GA00 housing with a dry cloth, with a focus on preventing dust and low-pressure spray water, and protecting the shaft end sealing structure with IP65 protection.

The operating environment temperature is controlled between 0 ℃ and+40 ℃, with humidity ≤ 85% (no condensation), avoiding contact with corrosive gases and adapting to harsh industrial environments.

The installation of coupling components adopts hot sleeves or specialized fixtures, and uses optical axis sealing design for positioning. It is forbidden to knock the shaft end to protect the precision bearings and shaft system.

The terminal block should be tightened with a torque of 1.2-1.5N · m, and multi strand wires should be crimped with copper noses, in compliance with NEC/CEC electrical safety regulations.

Every 12 months, check the insulation resistance of the winding to be ≥ 10M Ω, clean the dust on the heat dissipation surface, check the lubrication status of the bearings, and avoid abnormal noise faults.

Before restarting after being idle for more than 6 months, manually rotate the shaft to check its flexibility, preheat it for 30 minutes without load, and gradually load it to the rated torque for operation.

Summary: The stable operation core of Indramat MDD093C-N-020-N2L-130GA00 servo motor lies in standardized installation, drive matching, IP65 protection maintenance, and bearing maintenance. Relying on the high-precision and wide adaptability characteristics of synchronous motors, it can adapt to automation scenarios such as machine tools and robots. With compliant operation, it can fully leverage its industrial grade reliability and fast start advantages.

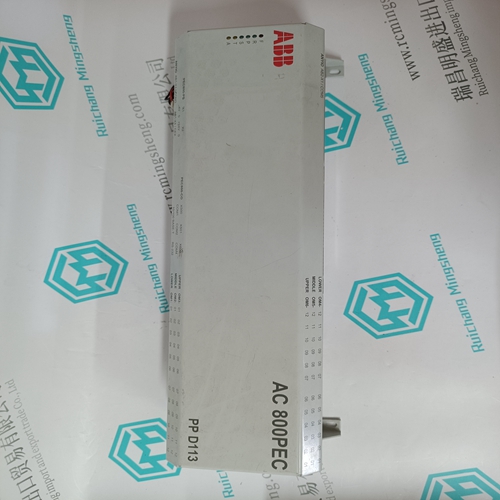

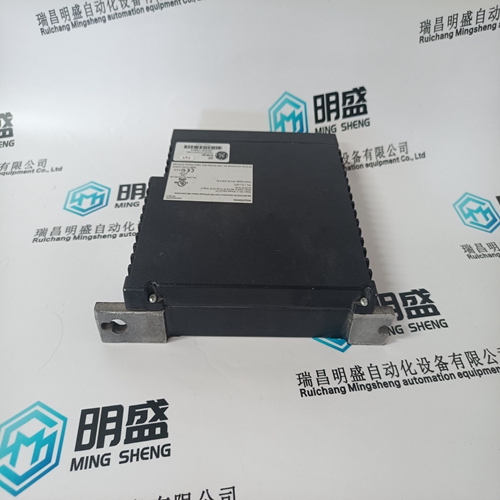

MDD093C-N-020-N2L-130GA00 Product imag

MDD093C-N-020-N2L-130GA00 ontroller Module

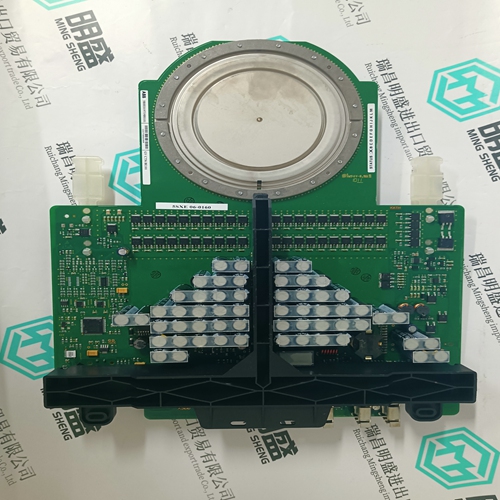

SAT RM3141-01-02 robot card

STEC S83-1003-01 switch interface module

TEAM BG0090 Automation module

Other website links

Honeywell 51303932-476串行设备接口模块

Honeywell 51305348-100媒体适配器

Honeywell 51405098-100接口模块

| 750-P5-G5-S5-HI-A20-R | 8020-SCP-522 | 8030-HQM-471 |

| 750-P5-G5-S5-HI-A20-G | 8020-SCP-521 | 8030-HOM-271 |

| 750-P5-G5-S1-HI-A20-R | 8020-SCP-452 | 8030-HOM-261 |

| 750-P5-G5-D5-HI-A20-R-E | 8020-SCP-444 | 8030-GOM-221 |

| 750-P5-G5-D5-HI-A20-R | 8005-LNC-101 | 8030-EQ5138-G2 |

| 750-P5-G5-D5-HI-A20-G | 8005-LCB-10 | 8030-EQ5138-G1 |

| 750-P5-G1-S1-LO-A1-R-E | 8005-FCB-10 | 8030-EQ5-138-G2 |