Home > Product > Gas turbine system > DT100LS4BM/HR gear motor

DT100LS4BM/HR gear motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:DT100LS4BM/HR

- Get the latest price:Click to consult

Product Details Introduction

The installation of SEW-EURODRIVE DT100LS4BM/HR requires the use of a B3 foot mounting bracket with a fixed torque of 150-180N · cm, suitable for a 100mm IEC machine base size, to avoid vibration displacement during operation.

Before wiring, confirm that the power supply voltage matches the rated 230/400VAC of DT100LS4BM/HR to prevent overvoltage damage to the 2.2kW power level winding and built-in AC brake coil.

This model integrates a gear reduction mechanism and needs to match the output speed according to the load requirements. It is recommended to optimize the transmission efficiency by configuring parameters through MOVITOOLS MotionStudio software.

The power cable should be made of copper wire with an area of ≥ 2.5mm ², and the brake coil should be wired separately. The multi strand wire should be crimped with a copper nose, and the terminal should be tightened with a torque of 1.2N · m.

Regularly clean the DT100LS4BM/HR casing with a dry cloth. IP55 protection should focus on preventing dust and splashing liquids, and protecting the gearbox sealing structure and shaft end oil seal.

The operating environment temperature should be controlled between -20 ℃ and+40 ℃, and the humidity should be ≤ 85% (no condensation). For corrosive environments, OS series surface protection upgrades should be selected.

Before starting SEW-EURODRIVE DT100LS4BM/HR, it is necessary to check the AC brake release status to ensure that the brake coil is energized before loading the load, in order to avoid gear impact damage.

The coupling installation utilizes a 28mm shaft diameter and 8mm keyway positioning, using specialized press fit tools. It is prohibited to strike the shaft end to protect the input shaft system of the gearbox.

Every 12 months, check the insulation resistance of the winding to be ≥ 5M Ω, and at the same time, check the lubricating oil level of the gearbox. Replace the dedicated gear oil every 5000 hours according to SEW specifications.

Before restarting after being idle for more than 6 months, manually rotate the output shaft to check its flexibility, preheat it for 20 minutes without load, gradually load it to the rated load, and avoid brake adhesion faults.

Summary: The stable operation core of SEW-EURODRIVE DT100LS4BM/HR gear motor lies in standardized installation, voltage matching, braking operation, and regular lubrication and maintenance. With a 2.2kW power, IP55 protection, and integrated deceleration design, it is suitable for industrial scenarios such as conveying equipment and machine tool auxiliary transmission. Combined with compliant operation, it can fully leverage its high reliability and transmission efficiency advantages.

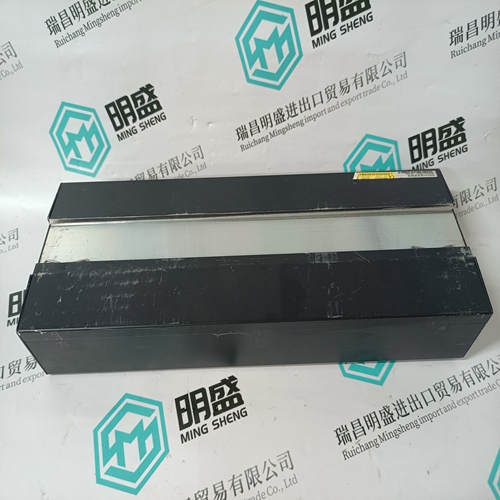

DT100LS4BM/HR Product imag

DT100LS4BM/HR ontroller Module

TEAM BL0170 Automatic card

TEAM BL0308 Automatic card

ACU-01B 3HNA024871-001/03 controller

Other website links

Honeywell 51305348-100媒体适配器

Honeywell 51405098-100接口模块

Honeywell 51401635-150通信和控制处理器

| 750-P5-G1-S1-HI-A20-R | 8005-EPU-1 | 8030-EQ5-138-G1 |

| 750-P5-G1-S1-HI-A20-G-E | 193X737ACG01 | 8030-DRK-300 |

| 750-P5-G1-D5-HI-A20-R | 531X100CCHAPM1 | 8030-DOM-221 |

| 750-P1-G1-S1-HI-A20-R-T-H | 531X111PSHAPG2 | 8030-DOM-101 |

| 750-P1-G1-S1-HI-A20-R | 531X111PSHATG3 | 8030-HOM-251 |

| 750-P1-G1-D1-HI-A20-R | 531X118CCAACG1 | 8030-HOM-241 |

| 745-W3-P5-G5-HI-R-E | 531X111PSHAWG3 | 8030-HOM-231 |