Home > Product > Servo control system > 5750001-ER DSTC190 Communication Board

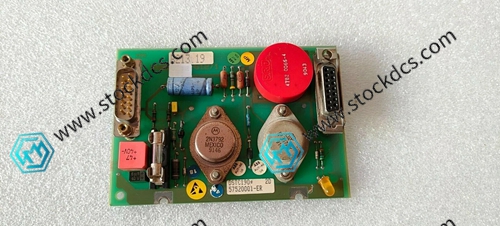

5750001-ER DSTC190 Communication Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:5750001-ER DSTC190

- Get the latest price:Click to consult

5750001-ER DSTC190 Communication Board

Product Details Introduction

5750001-ER DSTC190 Communication Board Usage Precautions

This board is an ABB industrial grade communication board, which is used for data exchange and link connection between industrial control system modules. It supports multiple types of serial interfaces and protocol adaptation. The following are 10 key usage points to ensure communication stability and equipment security.

1. Verify that the model is 5750001-ER DSTC190, confirm that the appearance is intact, the interface is not deformed or oxidized, ensure compatibility with the corresponding industrial control system and upstream and downstream modules, and record the serial number for traceability.

2. Carry out electrostatic protection throughout the process, wear a grounding wristband for operation, store and transport anti-static bags, stay away from strong electromagnetic interference, humidity, and vibration environments, and protect the board chips and communication interfaces.

3. Disconnect the main power supply before installation, wait for the circuit capacitor to discharge completely, clean the installation slot and board interface dust, fix them with matching kits, reserve space for heat dissipation and operation, and ensure that the wiring is neat and orderly.

4. Distinguish the signal and power interfaces accurately according to the identification, select shielded cables, separate them from the power cables, tighten the terminals to prevent virtual connections, and prevent misconnection from causing damage to the board or communication interruption.

5. Confirm that the power supply voltage meets the rated requirements, the grounding is reliable to avoid potential difference interference, and ensure the stability of interface signal transmission such as RS-232/RS-485.

6. During debugging, verify the compatibility between protocol adaptation status and communication parameters, test data transmission rate and accuracy, record core operating parameters, and ensure compliance with system control requirements.

7. Enable access permission protection to prevent illegal rewriting of communication configurations, and combine software and hardware protection mechanisms to ensure the security of link data and control logic.

8. During operation, monitor the status of the board and self diagnostic alarm information to avoid overloading the device, monitor the heat dissipation situation in real time, and prevent chip overheating or interface failures.

9. Regular power-off maintenance, cleaning of board dust and interface oxide layer, checking cable tightness, and troubleshooting for potential hazards such as poor contact and capacitor bulges.

10. When there is a malfunction, first disconnect the power and troubleshoot the link, interface, and compatibility issues. Use the self diagnostic function to locate the fault point, and contact professional personnel or manufacturer after-sales service for difficult problems.

Following the above points can fully leverage the performance of the DSTC190 communication board, ensure smooth and stable operation of industrial control system links, and adapt to industrial automation scenarios such as power, environmental protection, and manufacturing.

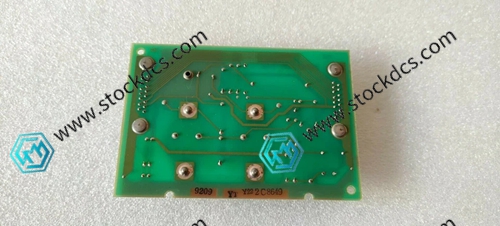

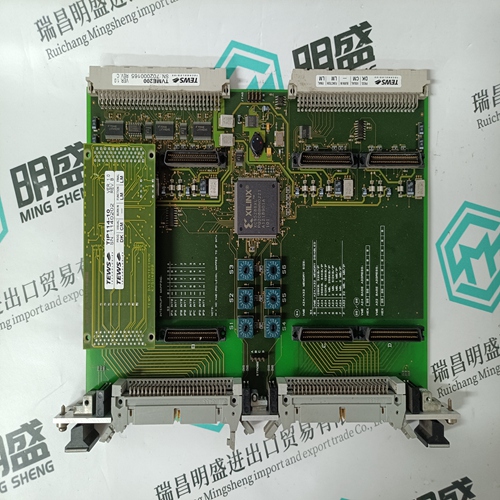

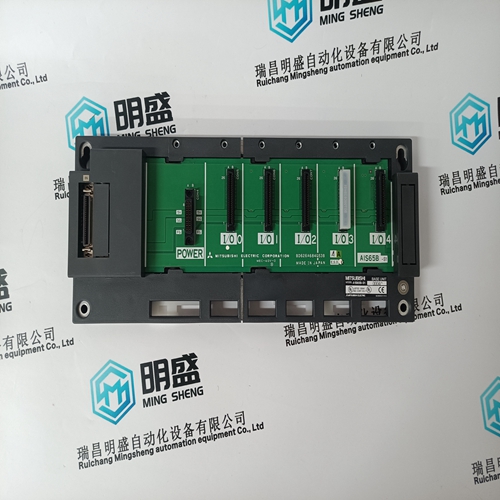

5750001-ER DSTC190 Product imag

5750001-ER DSTC190 ontroller Module

IC754VSF12CTD Quick Panel Control

Pacific Scientific SCE903AN-002-01 Digital Servo Driver

ORMEC SAC-SW220/EB controller

Other website links

IS220PsVOH1A 汽轮涡轮IO模块

HONEYWELL FC-TSAI-1620M模拟输入模块

HIMA F6706模拟量模块

| 710-650094-20 | 8030-CRM-230 | 740-607108-005 |

| 710-650044-20 | 8030-CRM-222 | 710-611867-000 |

| 710-615775-000 | 8030-CRM-220 | F31X170TBSACG1 |

| 710-613084 | 8030-CRM-214 | 073-655007-00 |

| 710-611725-002 | 8030-CRM-211R | 531X309SPCAHG1 |

| 710-610801-001 | 531X111PSHAPG3 | F31X111PSHARG1 |

| 710-610522-000 | 193X741ACG01 | 710-661726-00 |

| 710-609995-003 | 193X801DAG01 | 710-611487-001 |