Home > Product > Servo control system > 853-259817-104 controller module

853-259817-104 controller module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:853-259817-104

- Get the latest price:Click to consult

853-259817-104 controller module

Product Details Introduction

853-259817-104 Controller Module Core Product Application Fields

1. Process industry automation control: Suitable for continuous production scenarios in industries such as petrochemicals, fine chemicals, metallurgy, etc., it is used for temperature/pressure regulation of reaction vessels, liquid level control of distillation towers, closed-loop control of pipeline flow, etc. It seamlessly integrates with DCS systems through protocols such as PROFIBUS DP to ensure stable process parameters.

2. Energy and power system operation and maintenance: applied to energy scenarios such as thermal power generation, nuclear power, photovoltaic power plants, etc., to achieve auxiliary control of generator sets, coordination of new energy grid connection, monitoring of transmission and distribution equipment status, support anti backflow, peak shaving and valley filling strategies, and adapt to high voltage and strong electromagnetic interference environments.

3. Intelligent Control of Heating, Ventilation, and Air Conditioning (HVAC): For commercial complexes, data centers, clean rooms, and other scenarios, it controls air handling units, fresh air systems, fume hoods, and other equipment to achieve precise adjustment of temperature, humidity, and air quality through the BACnet protocol, compatible with intelligent sensor linkage control.

4. Industrial valve actuator drive: Used in scenarios such as oil and gas pipelines, urban gas, and water supply and drainage networks, it drives electric actuators to achieve precise control of valve opening, supports 4-20mA signal feedback, adapts to harsh working conditions such as explosion-proof and high vibration, and ensures fluid transportation stability.

5. Laser processing equipment control: Suitable for precision processing scenarios such as laser cutting, laser engraving, and laser welding, providing two axis/multi axis linkage control, pulse trigger signal output, supporting continuous interpolation algorithms for small line segments, and meeting high-precision machining trajectory control requirements.

6. Integration of intelligent manufacturing equipment: Embedded in automated production lines, dispensing machines, surface mount machines, screw locking machines, and other equipment to achieve multi station collaboration, motion trajectory planning, IO signal linkage control, compatible with PLCopen function blocks and API programming, and adaptable to flexible production needs in discrete manufacturing scenarios.

7. Rail transit auxiliary system: applied in scenarios such as train air conditioning control, brake system status monitoring, platform ventilation and smoke control, with a wide temperature range (-40 ℃~+85 ℃) and anti vibration performance, in compliance with electromagnetic compatibility standards in the rail transit industry.

8. Environmental Protection and Water Treatment Control: Suitable for water plant dosing systems, sewage treatment aeration tank control, industrial wastewater treatment equipment, to achieve water quality parameter monitoring, automatic adjustment of chemical dosage, sludge treatment process control, and support data exchange with environmental protection online monitoring platforms.

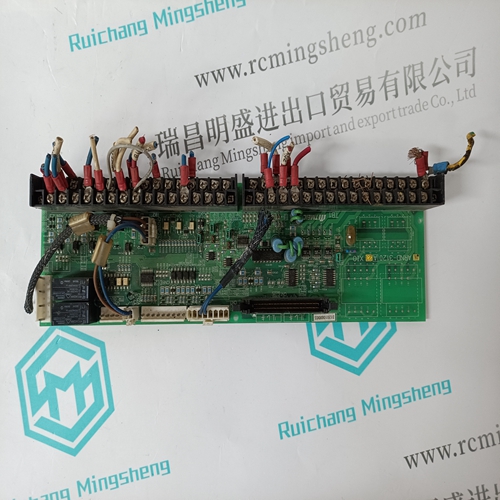

853-259817-104 Product imag

853-259817-104 ontroller Module

GE 04220FL11232A relay

BENTLY 1900/27 Monitor module

WOODWARD 5466-316 Servo speed governor

Other website links

VMIVME-7650-83H通讯模块

IS215UCVFH2BB伺服控制器

GOP2控制操作触摸屏

| PMB33E-10101-03 | 70 PR 03c-E | 57160001-ADK DSTX 170 |

| PMB33E-10101-02 | IMDSI02 | PMB33F-20200-03 |

| PMB33E-10101-01 | IIMSM01 | LR370A-E |

| PMB33E-10101-00 | AMAT 0100-00408 | PFRL101B 0.5KN |

| PMB33E-10100-03 | IEPAS02 | PFTL301E 1.0KN 3BSE019050R1000 |

| PMB33E-10100-02 | 07PS62R3 | 3BSE011181R1 PM511V16 |

| PMB33E-10100-01 | NIMF01 | PMB33F-20114-00 |