Home > Product > Robot control system > 1900-0711-81 Touchscreen Panel

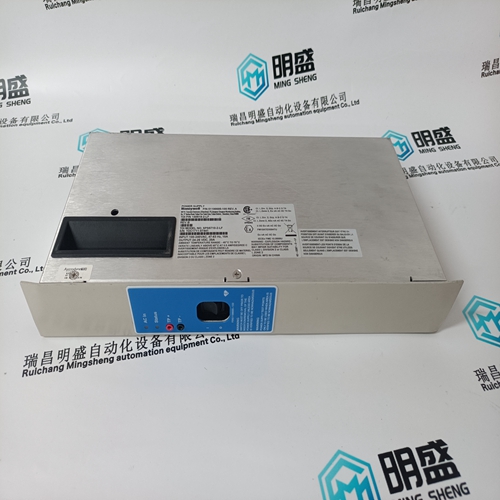

1900-0711-81 Touchscreen Panel

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1900-0711-81

- Get the latest price:Click to consult

1900-0711-81 Touchscreen Panel

Product Details Introduction

As a high-end servo inverter of Mitsubishi Electric MDS series, this product is designed with vector control technology as its core, specifically for medium and high-power precision equipment. It is a key driving component for scenarios such as CNC machine tools and industrial robots. Its core value lies in achieving precise conversion of electrical energy and closed-loop control of motors, balancing high-speed response and long-term stability, while being compatible with Mitsubishi M70/M80 series CNC systems, forming a complete control ecosystem.

Core performance and adaptation advantages

Power and control accuracy: With a rated output of 15kW and a heavy load current of 30A, when paired with a 1.5kW high inertia HC-SFS152 servo motor, the speed control accuracy can reach ± 0.01%, the position control error is only ± 0.005 °, and it can still output 150% of the rated torque at a low frequency of 0.3Hz, fully meeting the load requirements of precision machining.

Multi mode adaptation: supports four modes: V/F, open-loop/closed-loop vector and position control, which can be switched with one click through parameters to adapt to different working conditions such as impact load, tension control, high-frequency start stop, etc; 16 speed preset and PID adjustment function, simplifying the programming implementation of complex processes.

Communication and Expansion: Native compatible with Modbus RTU and Profibus DP buses, RS-485 interface with adjustable baud rate, optional FR-A7NC module for expandable Ethernet communication, enabling remote monitoring and parameter configuration, and adapting to factory distributed control networks.

Key specifications and environmental requirements

Power supply and protection: Suitable for 380-480V three-phase AC power, stable operation within ± 10% voltage fluctuation range; The IP20 protection level needs to be matched with a dry and dust-free computer room environment. The modular design (about 12kg) should be installed in a standard cabinet with a depth of ≥ 400mm, and the equipment spacing should be reserved at ≥ 100mm to ensure heat dissipation.

Interface configuration: 8-channel digital I/O, 0-10V/4-20mA analog input, supporting basic controls such as emergency stop and reset; Compatible with 17 bit absolute encoder feedback, the signal interface seamlessly connects with Mitsubishi servo motors without the need for additional conversion components.

Security guarantee: Built in overcurrent, overvoltage, overheating, phase loss, and motor overload protection, using Ith calculation method to accurately monitor motor temperature and avoid equipment damage; The acceleration and deceleration time is continuously adjustable from 0.01 to 3600 seconds, and the S-curve start function effectively reduces mechanical impact.

1900-0711-81 Product imag

1900-0711-81 ontroller Module

SCHNEIDE TCSESM043F2CS0 switches

SCHNEIDER TSXMRPC002M Analog features module

140CPU43412A CPU module

Other website links

216VC62A 处理器单元

HESG441635R1电源控制模块

216NG63A 数字量扩展模块

| PMB33F-20201-01 | IS420ESWBH1A | PM645B 3BSE010535R0001 |

| PMB33F-20201-00 | HONEYWELL CC-PCF901 | 6ES5470-7LB12 |

| PMB33F-20200-02 | Gespac ADC-12A GESADC-12A | 3500/42M |

| PMB33F-20200-00 | MDI32BIS | 6DD2920-0AR3 |

| PMB33F-20116-03 | DSCA190V 57310001-PK | PM253V01 |

| PMB33F-20116-01 | HONEYWELL 05701-A-0511 | 6DD2920-0AN1 |