Home > Product > Servo control system > 0C00122073 servo control system

0C00122073 servo control system

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:0C00122073

- Get the latest price:Click to consult

0C00122073 servo control system

Product Details Introduction

The installation of BALDOR SMARTMOVE 0C00122073 requires the use of an Eurocard frame with a fixed torque of 150-180N · cm to ensure vibration free displacement during multi axis operation.

Before wiring, confirm that the input voltage matches the rated specifications of 0C00122073. It is recommended to use a regulated power supply to avoid damaging the control module due to fluctuations.

The system supports servo/stepper hybrid axis control and requires configuring axis types and motion parameters through Mint programming software to adapt to complex trajectory requirements.

The communication cable should use shielded USB or RS232 cable, and the distance between the signal cable and the power cable should be ≥ 20cm to reduce electromagnetic interference and ensure data transmission.

Regularly clean the 0C00122073 heat dissipation holes and interfaces with a dry brush to prevent dust accumulation and poor heat dissipation or contact.

The operating environment temperature is controlled between 0 ℃ and+50 ℃, with a humidity of 5% -90% (no condensation), suitable for industrial automation scenarios.

Before starting BALDOR SMARTMOVE 0C00122073, self-tuning needs to be completed through Workbench software to optimize gain parameters and improve stability.

When tightening the wiring terminals, apply a torque of 1.0-1.2N · m and crimp multiple wires to the copper nose to avoid signal interruption or fault alarm caused by looseness.

Every 12 months, the insulation resistance of the system should be tested to be ≥ 5M Ω, and the Mint program and parameters should be backed up to identify potential hazards through fault codes.

Before restarting after being idle for more than 6 months, power on and preheat for 30 minutes, verify the accuracy of the axis movement under no load, and then gradually load it to the rated load.

Summary: The stable operation core of the BALDOR SMARTMOVE 0C00122073 servo control system lies in standardized installation, programming adaptation, communication protection, and regular maintenance. Relying on hybrid axis control, flexible programming, and improved protection functions, it is suitable for precision drive scenarios such as laser engraving and CNC machine tools. With compliant operation, it can fully leverage its high positioning accuracy and industrial grade reliability advantages, ensuring efficient operation of the automation system.

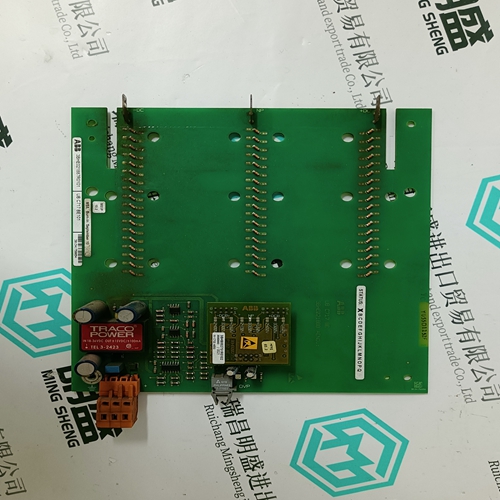

0C00122073 Product imag

0C00122073 ontroller Module

RAMIX PMC237C-008EMI connector card

SAT CM3141-02-03 CX3149-05 robot card

SAT CM3142-01-03 CX3147-04 Industrial Control Card PLC/DCS Spare Module

Other website links

FOXBORO FPS400-24 P0922YU电源模块

WOODWARD 8280-423数字控制模块

3BHB040288R0001终端单元

| 92407-01-1 | S60300-EI | 5347049-BR DSSX161 ABB |

| 92081-02-1 | CACR-SR05AB1ERY3-V | 26390603-A DSTK150 ABB |

| 92-005422-0x | CACR-PR30BC3CSY166E | PFCL301E |

| 90785-6-1 | 6DD1681-0DJ1 | 26390582-AY DSTK126 ABB |

| 90773-01-1 | CACR-SR30SZ1SDY230 | ABB UAC389AE02 HIEE300888R0002 |

| 8V1090.00-2 | CACR-SR-10SZ1SF | PFEA 113-65.4PXV |

| -8SL11 | CACR-HR10BABY5 | 26390603-BS DSTK181 ABB |