Home > Product > PLC programmable module > VT-HNC100-1-22/W-08-0-0 Digital Axis Controller

VT-HNC100-1-22/W-08-0-0 Digital Axis Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:VT-HNC100-1-22/W-08-0-0

- Get the latest price:Click to consult

VT-HNC100-1-22/W-08-0-0 Digital Axis Controller

Product Details Introduction

REXROTH VT-HNC100-1-22/W-08-0-0 is a German Bosch Rexroth VT-HNC100 series programmable digital axis controller designed specifically for electro-hydraulic hybrid drive systems.

Supporting independent control of 1-4 axes, it can achieve closed-loop control of electromechanical and electro-hydraulic drive, and adapt to the precise motion requirements of multiple working conditions.

Equipped with a 23 bit high-resolution encoder feedback, the repeated positioning accuracy reaches ± 0.001mm, meeting the requirements of micrometer level control scenarios.

The refresh cycle of the current loop is as low as 62.5 μ s, and the response frequency of the speed loop is 3kHz, which can instantly capture load changes and dynamically respond rapidly.

Built in PID controller and adaptive compensation algorithm, which can automatically adjust output parameters and optimize control process stability.

Supports industrial buses such as PROFIBUS DP and Modbus RTU, and is also compatible with RS485 communication, making it easy to interface with MES/ERP systems.

Equipped with three programmable jump frequency bands, it can avoid the risk of mechanical resonance and prevent mechanical damage during equipment operation.

Integrated with multiple protection functions such as overcurrent, overtemperature, and phase imbalance, the dual channel torque cutoff design certified by SIL3 ensures high safety redundancy.

REXROTH VT-HNC100-1-22/W-08-0-0 adopts a modular structure, which enables quick identification and replacement of faulty units, reducing downtime.

Compatible with MDD series servo motors and hydraulic actuators of the same brand, with strong system compatibility and lower integration costs.

Resistant to a wide temperature range of -40 ℃~85 ℃, with anti vibration and anti electromagnetic interference design, suitable for harsh industrial environments.

Supports three basic control modes: position, speed, and torque, and can expand advanced functions such as interpolation and synchronous control.

Equipped with an intuitive operating interface and LED status indicators, convenient parameter configuration, and support for PC based IndraWorks software simulation debugging.

The mean time between failures (MTBF) exceeds 100000 hours, the maintenance free cycle of core components reaches 5 years, and the operational reliability is excellent.

Widely used in precision machine tools, robots, automotive welding lines and other scenarios, especially suitable for high-end manufacturing equipment that requires multi axis collaboration.

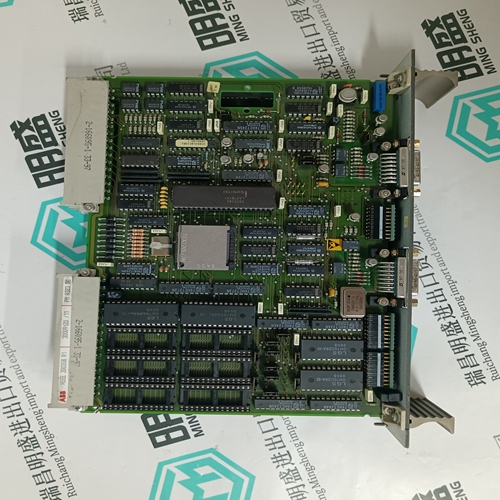

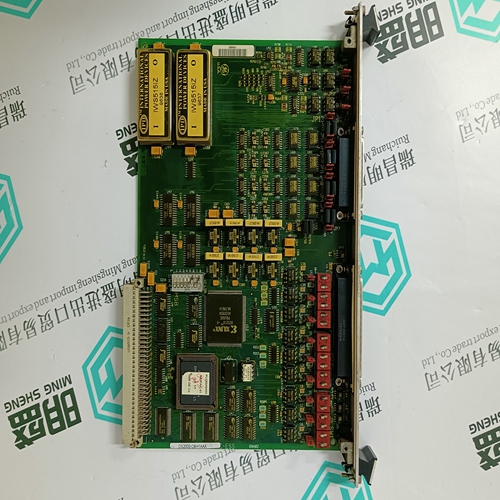

VT-HNC100-1-22/W-08-0-0 Product imag

VT-HNC100-1-22/W-08-0-0 ontroller Module

IS200AEPCH1BAA General electric (ge) card

IS200WETBH1ABA General electric (ge) module

IS210AEBIH3BEC Gas turbine electrical module

Other website links

Foxboro H92 H92A049E0700转换器

PPD117A3011 3BHE030410R3011激励控制器

TRICONEX 2000418数字输出模块

| 92661-02-1 | AMAT 0100-09115 | PFEA 113-65 |

| 92407-01-1 | S60300-EI | 5347049-BR DSSX161 ABB |

| 92081-02-1 | CACR-SR05AB1ERY3-V | 26390603-A DSTK150 ABB |

| 92-005422-0x | CACR-PR30BC3CSY166E | PFCL301E |

| 90785-6-1 | 6DD1681-0DJ1 | 26390582-AY DSTK126 ABB |

| 90773-01-1 | CACR-SR30SZ1SDY230 | ABB UAC389AE02 HIEE300888R0002 |

| 8V1090.00-2 | CACR-SR-10SZ1SF | PFEA 113-65.4PXV |