Home > Product > Gas turbine system > IMCPM02 Communication Port Module

IMCPM02 Communication Port Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IMCPM02

- Get the latest price:Click to consult

IMCPM02 Communication Port Module

Product Details Introduction

Application areas of IMCPM02 communication port module products (15 items)

1. Thermal power plant: adapted to Symphony Harmony system, using 32-bit processor to achieve low latency transmission of unit data (≤ 50ms), connecting DCS and SIS platforms.

2. Petroleum refining workshop: Through multi protocol compatibility, convert Modbus RTU and TCP/IP signals, and establish a high-speed communication link between PLC and the central control room.

3. Municipal sewage treatment plant: Enable fiber optic interface (transmission distance ≤ 2km) to stably transmit parameters such as sludge concentration and COD value to the SCADA system.

4. Non metallic ore processing plant: relying on RS485 serial port to interface with powder equipment, real-time data collection and command issuance of airflow crusher operation are achieved.

5. Metallurgical factory: With the ability to handle multiple tasks in parallel and manage 8 concurrent links, it coordinates the communication and data exchange between the blast furnace and the converter.

6. New energy photovoltaic power station: Through adaptive Ethernet interface, summarize inverter data and upload it to the energy management platform at high speed to ensure stable transmission.

7. Ocean platform: adapted to ATEX certification standards, with anti-corrosion design and fiber optic communication, to ensure the secure encryption and transmission of data for offshore equipment.

8. Pharmaceutical workshop: Compatible with multiple device communication protocols, achieving seamless integration between reaction vessels and control systems, meeting the real-time traceability requirements of production data.

9. Intelligent robot workshop: Connected to inspection robots through RS232 interface, transmitting positioning and task instructions, adapted to industrial collaboration scenarios.

10. Rail transit control center: relying on the fault self recovery function, it automatically reconnects after communication interruption to ensure continuous transmission of train braking system signals.

11. Battery material factory: Docking with powder modification production lines, synchronously collecting mixing and grinding equipment operating parameters through multi interface adaptation.

12. Data center room: With TCP/IP protocol adaptation capability, build a high-speed communication network between power distribution equipment and monitoring terminals, with low latency feedback status.

13. Underground mining operations: By using fiber optic interfaces to avoid electromagnetic interference, remote and stable communication between underground mining equipment and ground control can be achieved.

14. Chemical Industrial Park: Supports remote firmware upgrades, optimizes port parameters without downtime, and ensures continuous operation of cross regional device communication.

15. Laboratory testing: Compatible with Profibus DP protocol, compatible with non-standard testing equipment, achieving high-speed aggregation and transmission of diverse experimental data.

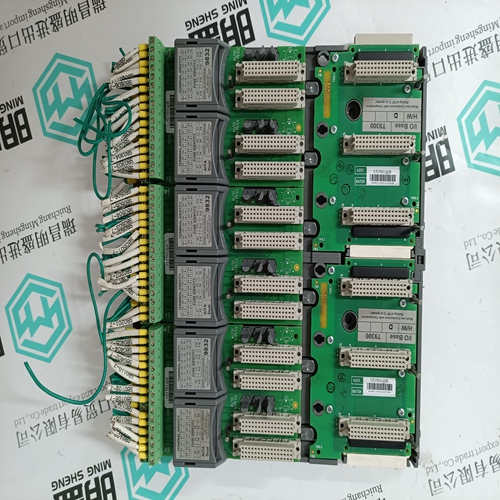

IMCPM02 Product imag

IMCPM02 ontroller Module

PARKER 87-008145-03 Servo Motor Driver

PROSOFT AN-X2-AB-DHRIO network conversion module

EMERSON VE3006 Distributed Control System

Other website links

VMIVME-017807-411001 VMIVME-017807-414001单板计算机

VME-7807RC-414001 350-93007807-414001单板计算机

GDD471A001 2UBA002322R0001 2UBA002322R0003高压变频器

| AMAT 0190-34538 | AMAT 0190-36769 | AMAT 0190-13487 |

| AMAT 0190-33452 | AMAT 0190-36774 | AMAT 0190-13511 |

| AMAT 0190-37775 | AMAT 0190-36793 | AMAT 0190-13557 |

| AMAT 0190-52419 | AMAT 0190-37099 02 | AMAT 0190-13605 |

| AMAT 0190-17464 | AMAT 0190-37178 | AMAT 0190-13625 |

| AMAT 0190-23562 | AMAT 0190-37200 | AMAT 0190-13626 |