Home > Product > DCS control system > 620-0086 Link Driver Module

620-0086 Link Driver Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:620-0086

- Get the latest price:Click to consult

Product Details Introduction

620-0086 Link Driver Module Product Application Fields

620-0086, as a Honeywell Parallel Link Driver Module (PLDM), focuses on high-speed parallel communication, fault management, and system adaptability. It is the core communication component of the 620 series control system and is widely used in 15 major fields:

1. Oil and gas: Build a parallel communication link between the control system and remote I/O to ensure high-speed transmission of data for oil and gas extraction and transportation.

2. Power generation: adapted to control systems of thermal power plants and substations, achieving low latency data exchange and fault response between processors and I/O devices.

3. Chemical processing: Tolerate complex working conditions, maintain synchronous communication and status control of equipment such as reactors and valves.

4. Metallurgical smelting: Build parallel data links in high-temperature environments to ensure stable linkage between smelting equipment and controllers.

5. Intelligent manufacturing: As a core link component of distributed control, it achieves high-speed data transmission and fault diagnosis through multi device collaboration.

6. Rail Transit: Adapt to the rail operation and maintenance control system, build low latency communication links, and ensure real-time feedback of equipment status.

7. Shipbuilding industry: Tolerate salt spray and high humidity, establish parallel communication links between engine room equipment and main control system, and improve navigation reliability.

8. Water treatment environmental protection: Maintain efficient communication between sewage treatment equipment and control systems to ensure accurate execution of operation and maintenance instructions.

9. Pharmaceutical production: Build a high-precision production system communication link to meet the requirements of data synchronization transmission and compliance control.

10. Food processing: Adapt to clean production environments and achieve stable parallel communication between production line equipment and main control units.

11. Automotive manufacturing: Build communication links for welding and assembly production lines to ensure high-speed data exchange for multi station equipment collaboration.

12. New energy power station: adapted to photovoltaic and energy storage power station systems, achieving parallel transmission of equipment status data and fault response.

13. Building automation: Build communication links between building equipment and central control systems to optimize the efficiency of HVAC and security equipment linkage.

14. Fire linkage: Establish a parallel communication link between fire equipment and the host to ensure fast transmission of instructions and status feedback.

15. Old system upgrade: Compatible with Honeywell 620 series architecture, upgrade communication links of old systems, and improve transmission reliability.

This module provides stable and reliable communication link solutions for automation systems in various industries with high-speed parallel transmission, strong fault control, and adaptability to harsh working conditions.

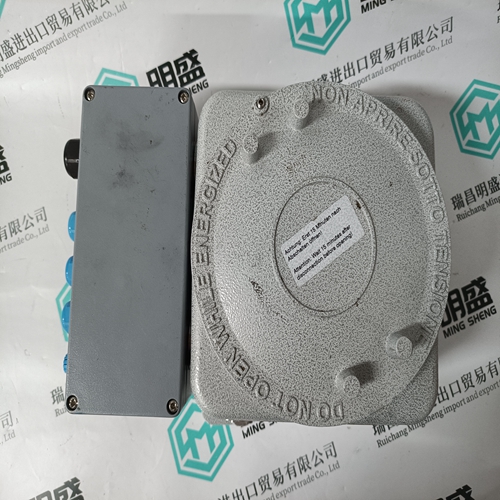

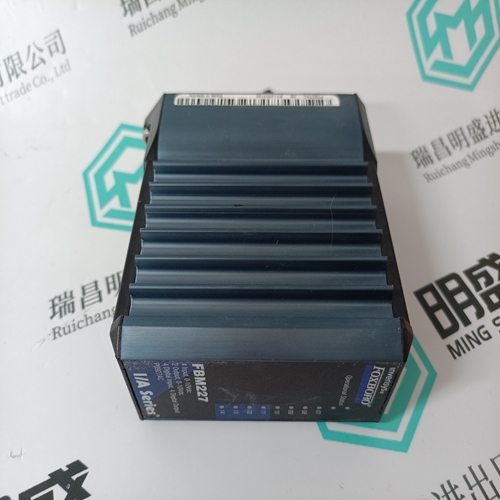

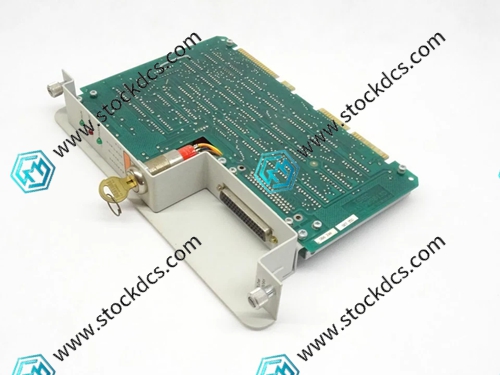

620-0086 Product imag

620-0086 ontroller Module

KOLLMORGEN S70601-SE Digital Output Module

HONEYWELL CC-TUIO31 I/O Module

CSA464AE monitoring module

Other website links

TRICONEX 3721输出冗余卡件

HESG216877K输入输出模块

216NG63A HESG441635R1输入输出模块

| 139-DO-FLC | 889-EP5P5G5LSSALAGAPFCSENNBN | 193X802DAG01 |

| 139-120V | 889-EP5P5G5HSSAANGMPFBSENNBN | 531X112PSAARG1 |

| 1300-50-01 | 889-EP5P5G5HRRALAGAPFCSENNBN | 193X805AEG03 |

| 10700-501 | 889-EP5P5G5HNNAANGMSFB3ASNBN | 6DD1684-0BC0 |

| 105-641001-01 | 869-EP5P5B5HSSAANGMSFBSENNBN | 531X111PSHAKG1 |