Home > Product > Robot control system > 192S06M0132B Control System Module

192S06M0132B Control System Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:192S06M0132B

- Get the latest price:Click to consult

192S06M0132B Control System Module

Product Details Introduction

192S06M0132B Control System Module Application Fields

The 192S06M0132B control system module has modular integration, fast networking adaptation, and precise closed-loop control capabilities. It supports signal acquisition and command execution linkage, is compatible with multiple sensors and actuators, and adapts to the control requirements of discrete manufacturing, intelligent equipment, and special scenarios. The specific applications are as follows:

1. Intelligent warehousing logistics: Manage AGV robot path planning and sorting equipment, coordinate shelf scheduling, and achieve automated warehousing circulation.

2. Semiconductor manufacturing equipment: adapted to wafer etching and packaging equipment, precise control of robotic arm movements and process gas flow.

3. Lithium battery production line: Control the coating and winding processes of battery cells, adjust pressure and speed parameters in real time, and ensure the consistency of battery cells.

4. Intelligent greenhouse planting: linked with temperature, humidity, and light sensors, automatically controlling shading, irrigation, and ventilation equipment, and regulating the growth environment.

5. Industrial oven temperature control: achieve multi-stage temperature curve control, adapt to electronic components and hardware baking processes, and ensure temperature control accuracy.

6. Rail transit signal control: used for platform screen doors and switch control modules to achieve signal linkage and safety interlocking.

7. Photovoltaic module testing equipment: Control EL detectors, power testers, and link transmission lines to achieve automated screening of module quality.

8. Packaging machinery control: adapted to filling, sealing, and labeling equipment, adjusting the operating cycle to ensure packaging accuracy and efficiency.

9. Cold chain cold storage control: Link refrigeration units with temperature sensing nodes to achieve zone temperature control and over temperature alarm, and retain operational data.

10. Robot welding workstation: controls the motion trajectory and welding parameters of the welding robot, and is suitable for welding automotive parts and steel structures.

11. Intelligent building automation: Control central air conditioning and fresh air systems, link fire signals, achieve energy optimization and emergency regulation.

12. Test bench measurement and control system: adapted to automotive and aviation component test benches, collecting mechanical and electrical parameters and closed-loop control.

13. Garbage incineration treatment: Control the feeding and blowing system of the incinerator, adjust the combustion conditions, and reduce harmful gas emissions.

14. Electronic manufacturing SMT equipment: controls the surface mount machine, reflow soldering furnace, and links material transportation to ensure surface mount accuracy and welding quality.

15. Special vehicle control system: adapted to engineering vehicles and sanitation vehicles, controls power output and operating devices, and enhances operational safety.

Note: The core advantages of the product are modular design, fast networking, and high-precision closed-loop control, supporting customized signal adaptation, and adapting to discrete manufacturing and special control scenarios.

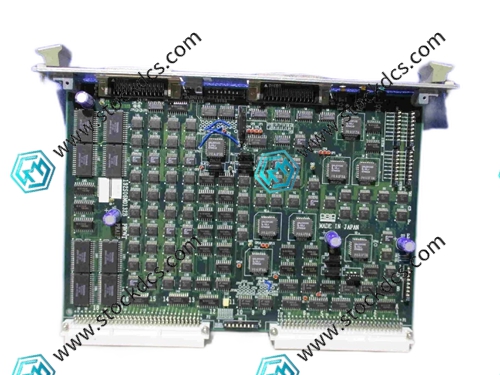

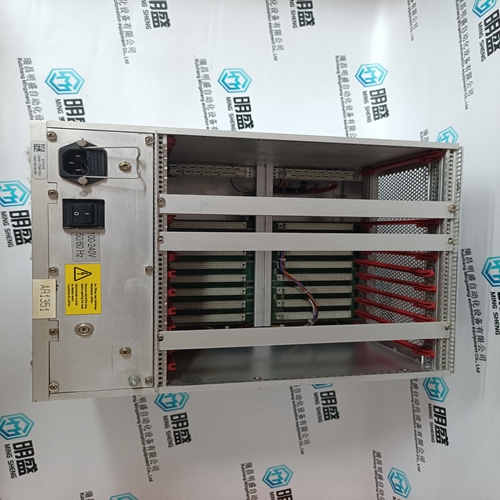

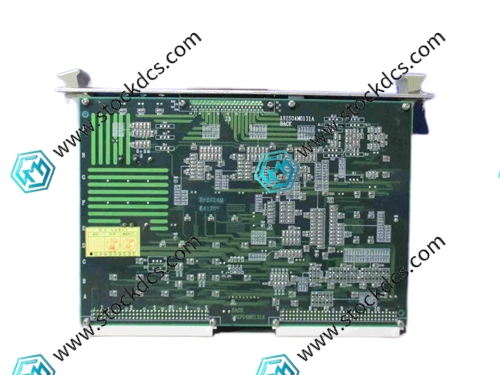

192S06M0132B Product imag

192S06M0132B ontroller Module

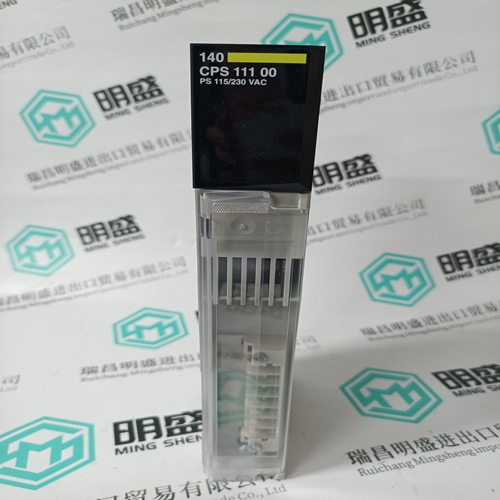

Woodward SST-SR4-CLX-RLL communication module

Bently 3500/91 190782-01 Communication Gateway Module

FOXBORO FBM204 processor module

Other website links

honeywell 05701-A-0326控制器卡件

HONEYWELL 05701-A-0301运动控制卡

UNS 0121A-Z,V1 UN1010-0001自动电压调节器

| 33VM62-220-6 | SBFP1-2222-48-23000 | IC3600VORA1A |

| 33VM62-220-3 | S20660-SRS | 073-650098-00 |

| 33VM62-220-19 | S60100-EI | 710-400180-000 |

| 33VM62-220-17 | SL3401-01000 | 073-500100-00 |

| 33VM62-220-16 | CACR-SR20TZ0SF-E | 740-689986-001 |

| 33VM62-220-1 | 6SC6500-0NA02 | 820-10736-000-H |