Home > Product > Robot control system > 192S04M0131A Distributed Control System

192S04M0131A Distributed Control System

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:192S04M0131A

- Get the latest price:Click to consult

192S04M0131A Distributed Control System

Product Details Introduction

192S04M0131A Distributed Control System (DCS) Application Fields

The 192S04M0131A distributed control system (DCS) has centralized monitoring and management, decentralized control execution capabilities, supports redundant communication and multi protocol compatibility, can achieve precise control of process parameters, alarm and warning, and data traceability, and is suitable for the process oriented production and operation and maintenance needs of various industries. The specific applications are as follows:

1. Petrochemical production: Control catalytic cracking and distillation units, achieve temperature and pressure cascade control, and integrate safety interlock functions.

2. Thermal power plants: Coordinate boiler and turbine systems, optimize combustion efficiency, ensure stable operation of units and load regulation.

3. Metallurgical smelting engineering: Control the ironmaking and steelmaking processes of blast furnaces, accurately regulate material ratios and furnace temperature and pressure parameters.

4. New energy photovoltaic power station: Cluster controlled inverters, responding to grid scheduling, achieving dynamic power regulation and data collection.

5. Sewage treatment plant: Adaptive control of dissolved oxygen concentration in the aeration tank, dynamic adjustment of dosage, and improvement of sewage treatment efficiency.

6. Pulp and paper industry: Control the entire process of pulp and paper making, stabilize key process parameters such as pulp concentration and paper thickness.

7. Cement production enterprises: covering raw material grinding and calcination processes, optimizing kiln operation, reducing energy consumption and pollutant emissions.

8. Urban cogeneration: Coordinate the cooling, heating, and power system to achieve efficient energy distribution and supply-demand balance regulation.

9. Coal chemical project: Control the production process of synthetic ammonia and methanol to ensure safe and stable operation under high pressure and high temperature conditions.

10. Food fermentation industry: Accurately control the temperature, humidity, and pH value of fermentation tanks to achieve process consistency in batch production.

11. Pharmaceutical production workshop: Complies with GMP standards, controls sterile production processes, and generates electronic batch records for easy traceability.

12. Hydroelectric power station: Control the water turbine and generator set to achieve precise control of water level regulation and power generation.

13. Coal mining and processing: Control mine ventilation and lifting systems, monitor gas concentration, and ensure production safety.

14. Intelligent water supply network: Balance the pressure of the water supply network, monitor flow leaks, reduce the risk of pipe bursting and water resource loss.

15. Ship Power System: Control the operation of the ship's main and auxiliary engines, monitor real-time operating parameters, and ensure safe and stable navigation.

Note: The core advantages of the product are high reliability, redundant fault tolerance, and flexible scalability, supporting multi protocol integration, and adapting to complex industrial working conditions and large-scale control requirements.

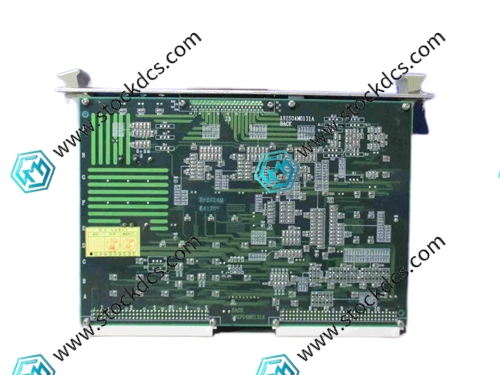

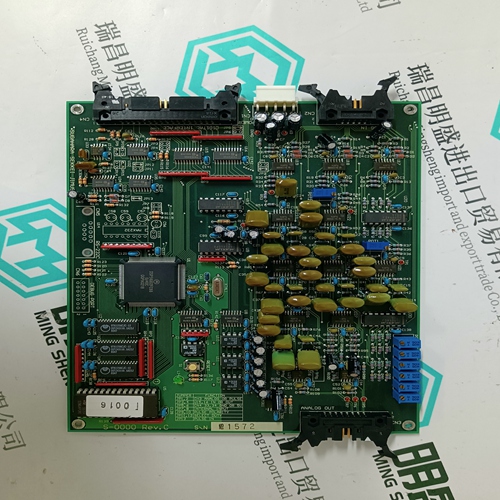

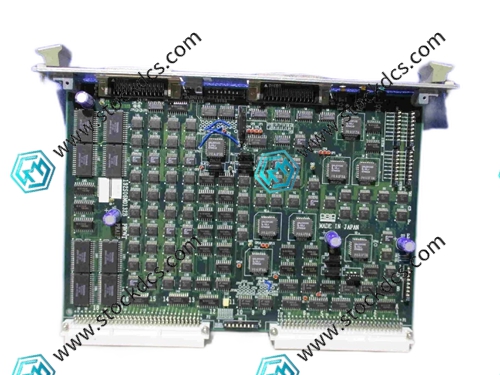

192S04M0131A Product imag

192S04M0131A ontroller Module

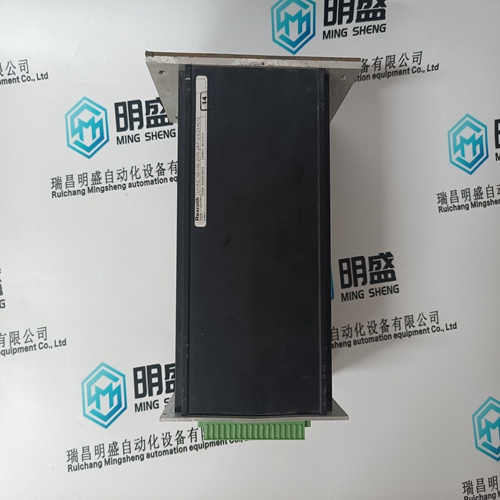

AB 1756-IF8I Control System Module

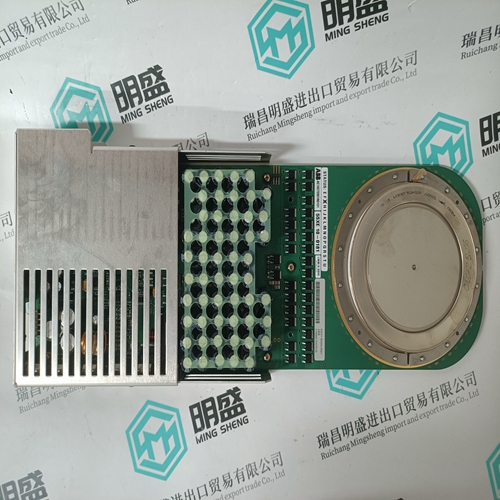

Woodward SST-SR4-CLX-RLL communication module

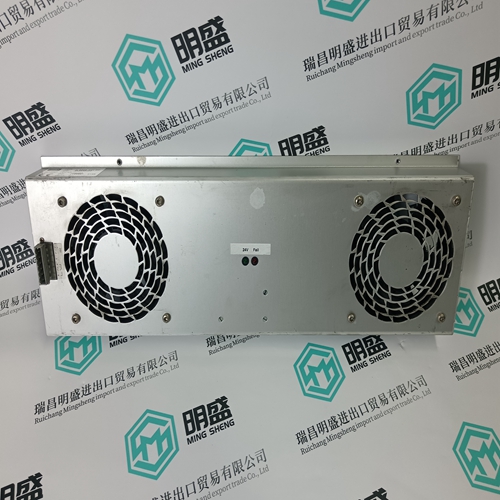

Bently 3500/91 190782-01 Communication Gateway Module

Other website links

Bentley 1900/65A-01-01-01-00-00振动监测器

honeywell 05701-A-0326控制器卡件

HONEYWELL 05701-A-0301运动控制卡

| 345-E-P5-G5-H-E-M-N-N-2E-N-N | AMAT 0100-09117 | IC3600VRCC1A |

| 345-E-P1-G1-L-E-E-N-N-SN-D-N | AMAT 0100-03012 | IC3600VRCC1 |

| 345-E-P1-G1-H-E-S-N-N-SN-D-N | AMAT 0100-20026 | IC3600VRCA1 |

| 345-E-P1-G1-H-E-S-N-N-1E-N-N | AMAT 0100-77064 | 067-11732-0003 |

| 33VM82-020-19 | AMAT 0100-01884 | CE3100-423-0 |

| 33VM82-020-15 | 6SC9836-0FA03 | 04-1086-00 |