Home > Product > DCS control system > ZM12-1600 laser cutting machine module

ZM12-1600 laser cutting machine module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ZM12-1600

- Get the latest price:Click to consult

ZM12-1600 laser cutting machine module

Product Details Introduction

1、 High power laser source module, efficient cutting core

Equipped with a 12000W single module continuous fiber laser, the power redundancy reaches 1000W, the stability error is ≤± 1%, and the cutting speed of medium and thin plates is comparable to that of 20000W level equipment. Adopting multiple anti high reflectivity designs, it is suitable for various materials such as carbon steel, stainless steel, aluminum alloy, etc. The cutting efficiency of 6mm carbon steel is increased by 85% compared to conventional models, and the processing cost of 10mm stainless steel is reduced by more than 40%. The electro-optical conversion efficiency exceeds 30%, and the energy consumption is only one-third of that of traditional plasma cutting equipment, which meets the green production standards.

2、 Precision cutting head module, precise positioning and cutting

Equipped with a coaxial visual focusing system, the collimating and focusing lenses adopt a multi piece combination design, with extremely small focusing spots and a cutting width of only 0.1-0.3mm, with a cutting accuracy of ± 0.1mm. It supports automatic focusing function, with a vertical adjustment range of ± 7mm for focal length, and can be adapted to different thicknesses of 0.5-25mm without manual parameter adjustment. Adopting a sealed protective design, the nozzle aperture can be selected from 0.5-2mm, combined with a maximum cutting pressure of 25bar, effectively blowing away slag and ensuring a smooth cutting section.

3、 Multi axis control system module, flexible and intelligent operation

Supports up to 16 axis linkage control, with a pulse output frequency of up to 10MHz, capable of linear, circular arc, and spiral interpolation operations, meeting the requirements of complex trajectory machining. Compatible with hard wire and bus control (EtherCAT/Profinet, etc.), can interface with PLC and MES systems, supports intelligent production scheduling and one click changeover, and completes program switching within 30 seconds. Built in position latch, electronic cam and other functions, combined with pulse closed-loop control, dynamically correct operating deviations, and improve trajectory consistency.

4、 Stability assurance module, adapted to harsh working conditions

Adopting a dual blade impeller cooling system, the fan speed is adjustable from 800-1600rpm, with high heat dissipation efficiency, and the equipment can operate continuously for 24 hours without overheating risk. The auxiliary gas system supports switching between multiple types of gases such as oxygen and nitrogen, accurately controls flow and pressure, adapts to cutting needs of different materials, prevents oxidation, and improves cutting quality. The protection level of the core components reaches IP67, which can resist dust and oil erosion, with a long design life and low maintenance frequency.

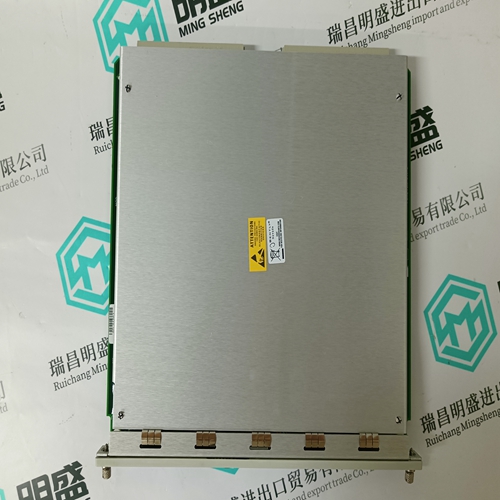

ZM12-1600 Product imag

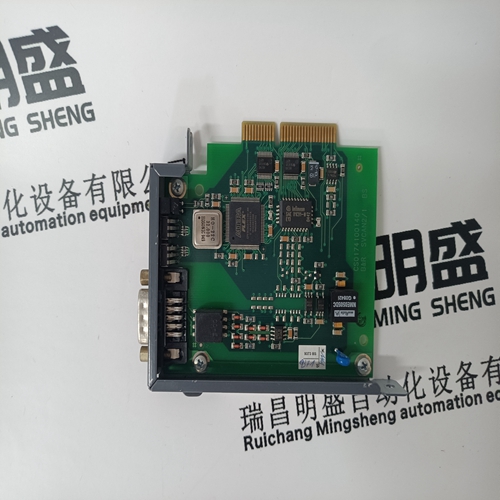

ZM12-1600 ontroller Module

UFC789AE 38HE014022P102 Excitation Control Board

LXN1604-6 3BHL000986P7000 power converter

XVC770BE101 3BHE02103R0101 interface board

Other website links

HIMA F8650E 安全系统中央模块

HONEYWELL 51309152-175C模拟输出模块

HONEYWELL 51304489-100模拟输入模块

| AMAT 0100-00086 | TP-7636-2 | PFTL7018 5.0KN 3BSE004191R1 |

| AMAT 0100-00689 | TP-7775-1 | 8237-1597 |

| AMAT 0100-09063 | TP-7919-1 | PPD113B01-10-150000 3BHE0237 |

| AMAT 0100-13025 | TP-8002-3 | 5SHY3545L0009 3HB013085R00C |

| AMAT 0100-00080 | TP-8059-0 | HYDRAN M2 |

| AMAT 0100-71141 | TP-8076-2 | K2-200 CP253/W |

| AMAT 0100-09235 | TP-8088-1 | OP362-LD/-5200 |