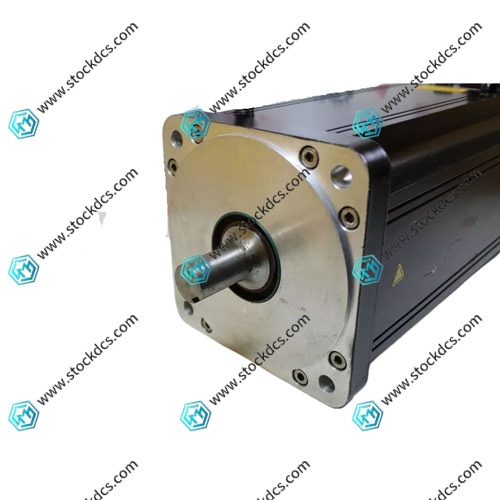

Home > Product > Robot control system > MPM1901-1534 servo motor

MPM1901-1534 servo motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MPM1901-1534

- Get the latest price:Click to consult

Product Details Introduction

The installation of MTS MPM1901-1534 requires the use of high-strength flange brackets with a fixed torque of 180-220N · cm to avoid vibration displacement during high-power operation.

Before wiring, confirm that the power supply voltage matches the rated 400VAC of MPM1901-1534 to prevent overvoltage damage to the 9.7kW power level winding.

This model supports position/speed/torque three mode control, and needs to match the dedicated drive according to the hardware ID to ensure adaptability.

The encoder signal line is separately wired using shielded twisted pair cables, with the joints locked in place to reduce electromagnetic interference and ensure signal stability.

Regularly clean the MPM1901-1534 casing with a dry cloth, with a focus on protecting against dust and high-pressure flushing water ingress for IP65 protection.

The operating environment temperature should be controlled between -20 ℃ and+70 ℃. If the temperature exceeds the limit, the capacity should be reduced by 2%/℃ to avoid overheating affecting performance.

If equipped with a brake function, the brake coil needs to be energized and released before starting MTS MPM1901-1534 to prevent load shock.

The installation of coupling components adopts hot sleeves or specialized fixtures, and it is forbidden to knock the shaft end to protect the keyway and bearing precision structure.

Every 12 months, check the insulation resistance of the winding to be ≥ 10M Ω, and clean the dust on the heat dissipation fins to ensure high power heat dissipation efficiency.

Before restarting after being idle for more than 6 months, manually rotate the shaft to check its flexibility, preheat it for 30 minutes without load, and gradually load it to the rated load.

Summary: The stable operation core of MTS MPM1901-1534 servo motor lies in standardized installation, voltage matching, protective maintenance, and load adaptation. Relying on the advantages of 9.7kW high power, 2800r/min high speed, and IP65 protection, coupled with compliant operation, it can fully exert its industrial grade power performance and reliability, ensuring efficient operation of heavy automation equipment.

MPM1901-1534 Product imag

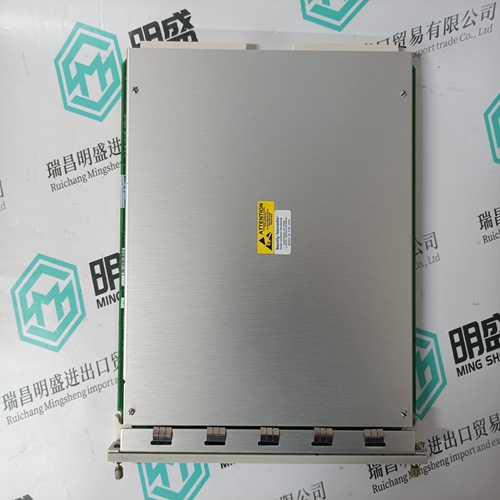

MPM1901-1534 ontroller Module

P4LQA HENF209736R0003 Control module

RAMIX PMC008A 700502 connector module

RAMIX PMC237C-008EMI connector card

Other website links

A30-30-10RT接触器

Bently 3500/15E 164949-01电源模块

KOLLMORGEN 6SM37M-6000伺服电机

| BA3614-5034 | SS9B-LB123 | 97-9037-03 |

| BA3614-4648-9-56BC | HZ40A60818 | EXM-17 |

| BA3608-1699-48B | H2-1522-1151 | 060-03644-0000 |

| AWC 500 | AMAT 0100-51017 | 44308902 |

| AMC 300 | AMAT 0100-90522 | 330878-90-00 |

| ALSTOM V4555724-0100 | AMAT 0100-76088 | 3500/22 146031-01 |

| AGL 400 | AMAT 0100-01714 | CE945GM2A-T25 |