Home > Product > DCS control system > 2EX100.50-1 Controller Module

2EX100.50-1 Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:2EX100.50-1

- Get the latest price:Click to consult

Product Details Introduction

The installation of 2EX100.50-1 requires compatibility with the B&R System 2010 rack, with a fixed torque controlled between 150-180N · cm to ensure a flat and secure installation surface.

Before wiring, confirm that the input voltage is compliant (recommended 24VDC ± 10%) to avoid overvoltage damage to the 2EX100.50-1 internal bus control module.

2EX100.50-1 supports mainstream communication protocols such as Modbus and Profinet, and needs to match the protocol version with the slave device to ensure stable data transmission.

The signal cable and power cable are wired separately (with a spacing of ≥ 20cm) and shielded to reduce electromagnetic interference to 2EX100.50-1, in compliance with the IEC 61131-2 EMC standard.

Regularly clean the interface contacts of 2EX100.50-1, use a dry brush to remove dust, and prevent poor contact or signal interruption.

The operating environment temperature is controlled between -10 ℃ and+60 ℃, with a humidity of 20% -85% (no condensation), suitable for its industrial grade working range.

After configuring the 2EX100.50-1 parameters, they need to be backed up through dedicated software, and key parameters should be recorded to prevent configuration loss caused by misoperation.

When disassembling the module, it is necessary to first disconnect the power supply of the power rack and wait for the indicator light to completely turn off before operating. It is forbidden to plug and unplug 2EX100.50-1 with power on to avoid interface damage.

When expanding I/O modules, 2EX100.50-1 can accommodate up to 32 expansion units and supports various module combinations such as digital and analog.

Attention should be paid to signal polarity in analog input wiring to avoid reverse connection, which may cause damage to the AD conversion module of 2EX100.50-1.

Regularly check the heat dissipation of 2EX100.50-1, and keep the rack ventilation openings unobstructed to avoid covering foreign objects that may affect heat dissipation.

When a communication failure occurs, first check whether the bus terminal resistance (recommended 120 Ω) of 2EX100.50-1 is installed properly.

Do not touch the 2EX100.50-1 terminal block with sharp tools to prevent damage to the pins or short circuits.

After long-term operation, verify the communication delay and data transmission accuracy of 2EX100.50-1 every 6 months and adjust the parameters in a timely manner.

After being idle for more than 3 months and restarting, it is necessary to first power on and preheat for 30 minutes before gradually loading the load to protect the internal capacitors and circuits.

Summary: The key to the stable operation of the 2EX100.50-1 controller module lies in standardized installation, protocol matching, EMC protection, environmental adaptation, and regular maintenance. Its support for multi protocol communication and flexible I/O expansion, combined with compliant operation, can fully leverage the high reliability and adaptability advantages of bus control, effectively ensuring the continuous and stable operation of industrial automation systems.

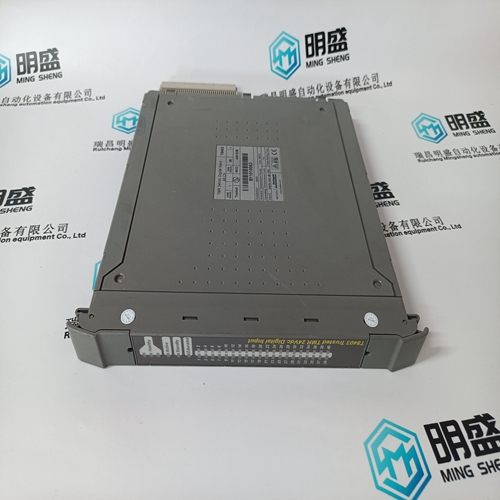

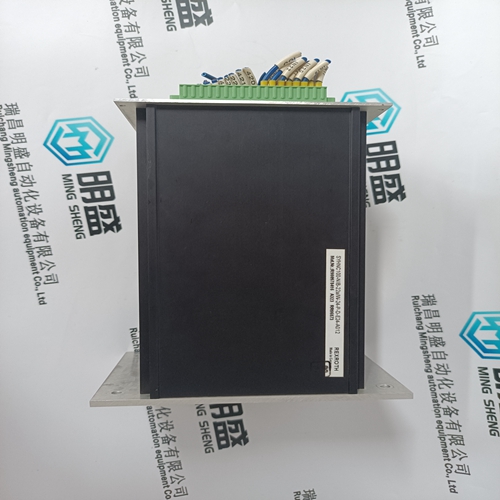

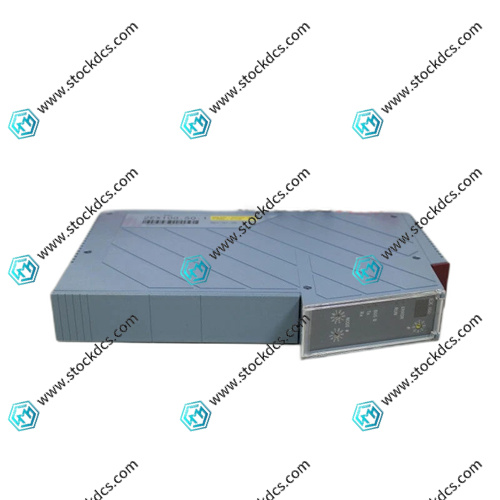

2EX100.50-1 Product imag

2EX100.50-1 ontroller Module

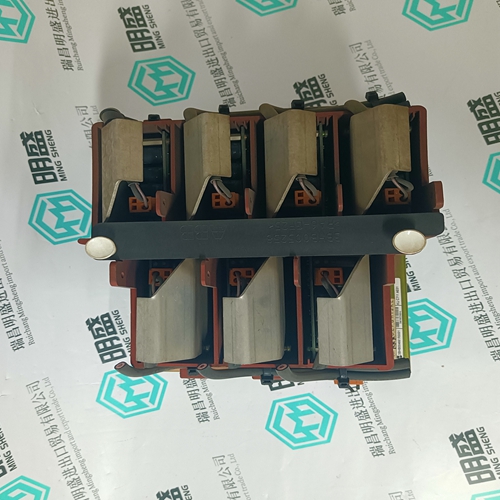

BRAKE BCC-1 Brake control card

IS215UCVEM08B IS215UCVEH2AE combustion engine card

VMIVME-7614-132 350-017614-132 D combustion engine card

Other website links

T3N225断路器

TRICONEX 8310 电源模块

1TGE120011R1111 控制器模块

| DO3201-A-V001 | CACR-SR05AC2ER | NMF01 |

| DI3201-A-V001 | 6DD1660-0AH1 | NRI002 |

| DBC-1 | CACR-SR02AC1ER, | NSPM01 |

| CU834-002 | CACR-IR15SFD | NMFC05 |

| CU833-002 | CACR-SR20SB1AFY100 | NLIM02 |

| CU832-001 | 6SC6506-4AA01 | IMMFP01 |