Home > Product > DCS control system > MDFKABA090-22 servo motor

MDFKABA090-22 servo motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MDFKABA090-22

- Get the latest price:Click to consult

Product Details Introduction

When installing Lenze MDFKABA090-22, the coaxiality between the motor and the load should be ≤ 0.1mm to reduce the impact of vibration on high dynamic response performance.

Handle the motor body tightly during transportation, and it is strictly prohibited to grip the encoder end or junction box of MDFKABA090-22 to avoid damaging precision signal components.

Lenze MDFKABA090-22 supports position/speed/torque three mode control, and switching needs to be configured through 9300 series servo controller.

When wiring, separate the encoder signal line from the power cable and ensure proper shielding and grounding to reduce interference with MDFKABA090-22 signal transmission.

Regularly clean the encoder window of Lenze MDFKABA090-22, with an IP54 protection level that focuses on preventing dust and splashing liquids from entering.

The operating environment temperature is controlled between -10 ℃ and+40 ℃, suitable for MDFKABA090-22 industrial grade thermal design. If the temperature is above 40 ℃, it needs to be used with reduced capacity.

The motor bearings are designed to be sealed and maintenance free, without the need for additional lubricating grease, to avoid disassembly and damage to the protective structure of Lenze MDFKABA090-22.

Avoid applying axial loads beyond the rated value to MDFKABA090-22, protect the shaft system and keyway structure (compatible with 8mm standard keys).

The tightening torque of the terminal block should be controlled between 120-150N · cm to prevent looseness from causing unstable power supply to Lenze MDFKABA090-22.

The bending radius of the supporting cable shall not be less than 10 times the diameter of the cable, and the sealing surface of the junction box shall be kept clean to avoid affecting the protective effect.

If the shell temperature of MDFKABA090-22 exceeds 85 ℃ during operation, it is necessary to shut down and check the load and heat dissipation to avoid overheating of the winding.

Disassembling the coupling components requires the use of a specialized puller, and it is forbidden to strike the shaft end to protect the axis accuracy of Lenze MDFKABA090-22.

Regularly verify the integrity of the encoder wiring to ensure compatibility with the high-precision feedback function and controller of MDFKABA090-22.

The surface of the motor needs to be kept clean, and dust should be removed with compressed air to ensure the heat dissipation efficiency of the cooling ribs and improve operational stability.

After being idle for a long time and restarting, it is necessary to first check that the insulation resistance of the winding is ≥ 5M Ω, confirm that there is no condensation, and then gradually test run at the rated speed.

Summary: The stable operation core of Lenze MDFKABA090-22 servo motor lies in standardized installation, precise protection, and load adaptation, with a focus on coaxiality control, IP54 protection maintenance, encoder signal protection, and environmental temperature control. It fully utilizes its advantages of high power density, low moment of inertia, and industrial reliability. Paired with the 9300 series controller, it can maximize the overall operating efficiency and service life of the equipment.

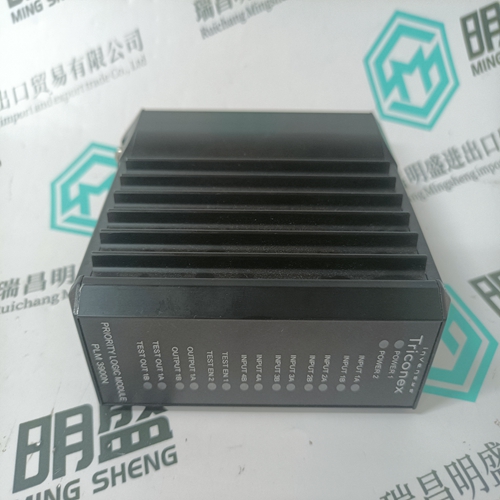

MDFKABA090-22 Product imag

MDFKABA090-22 ontroller Module

B&R 8AC120.60-1 Servo drive card

BRAKE BCC-1 Brake control card

IS215UCVEM08B IS215UCVEH2AE combustion engine card

Other website links

TRICONEX 3704E模拟输入模块

REXROTH VT-VPCD-1-16/V0/1-P-1 R901089559放大器模块

Woodward 9907-1183涡轮控制模块

| E10038-33VM61-030 | 531X122PCNALG1 | 6ES5451-8MA12 |

| DVC 550 | 531X122PCNAKG1 | NMFC01 |

| DVC 310 | 531X122PCNAHG1 | PCS124PS-200 |

| DS200SIOBH1A | 531X122PCNAEG1 | NTAI02 |

| DS200DCFBG1BLC | 531X122PCNACG1 | NLIS01 |

| DS200DCFBG1B | 531X121PCRALG1 | NSSM01 |

| DS200DCFBG1A | 531X121PCRAKG1 | PCS105PS-400 |