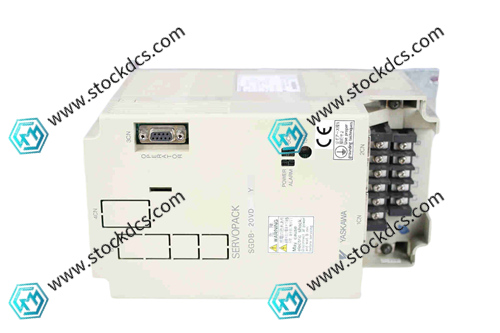

Home > Product > DCS control system > SGDB-20VDY85 servo controller

SGDB-20VDY85 servo controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:SGDB-20VDY85

- Get the latest price:Click to consult

Product Details Introduction

When installing YASKAWA SGDB-20VDY85, it needs to be fixed on a metal bracket with good heat dissipation, leaving a heat dissipation space of ≥ 10cm.

Before wiring, confirm that the power supply voltage matches the rated input of SGDB-20VDY85 to avoid damaging the internal module due to overvoltage.

YASKAWA SGDB-20VDY85 supports position/speed/torque control modes, and the controller needs to be restarted to take effect when switching.

The main circuit wiring should use copper wires with an area of ≥ 2.5mm ², and the terminals should be tightened according to the specified torque to prevent poor contact.

Regularly backup the parameter configuration of SGDB-20VDY85 to avoid parameter loss caused by misoperation and affecting operation.

The encoder signal line should be routed away from the power cable to reduce the impact of electromagnetic interference on YASKAWA SGDB-20VDY85 signal detection.

If SGDB-20VDY85 reports overcurrent fault during operation, it is necessary to first check the insulation of the motor winding and cable damage.

When cleaning the controller, disconnect the power and wipe the outer shell with a dry cloth. Do not use water or organic solvents.

The braking resistor of YASKAWA SGDB-20VDY85 needs to be selected according to the manual specifications to avoid overheating caused by insufficient capacity.

Regularly check the operation status of the cooling fan, and replace it promptly if it stops running to ensure the cooling efficiency of SGDB-20VDY85.

When adjusting the electronic gear ratio, it is necessary to combine the motor resolution and load requirements to ensure the positioning accuracy of SGDB-20VDY85.

Do not plug or unplug connectors during the operation of SGDB-20VDY85 to prevent instantaneous current from damaging the interface chip.

The environmental humidity should be controlled between 20% and 85% (without condensation) to avoid moisture causing internal short circuits in YASKAWA SGDB-20VDY85.

After the fault alarm is triggered, the alarm code should be cleared first, the root cause should be investigated before restarting, and forced reset operation is prohibited.

Before long-term shutdown, the power should be disconnected and preheated for 30 minutes every 3 months to protect the internal capacitor of SGDB-20VDY85.

Summary: The stable operation core of YASKAWA SGDB-20VDY85 servo controller lies in standardized installation, correct wiring, parameter backup, and environmental adaptation, with a focus on heat dissipation protection, electromagnetic compatibility, and fault compliance handling. It fully utilizes its precise control and high reliability advantages of 2kW power level to extend the overall service life of the equipment.

SGDB-20VDY85 Product imag

SGDB-20VDY85 ontroller Module

SR750-P5-G5-S5-HI-A20-R-T Relay shell

033.733.002.S Dc channel CARDS

B&R 8AC110.60-2 driver card

Other website links

SR750-P5-G5-S5-HI-A20-R-T Relay shell

033.733.002.S Dc channel CARDS

B&R 8AC110.60-2 driver card

| F45FENA-R2-NS-VS-00 | 531X126SNDADG1 | F31X187VCTACG1 |

| F45FENA-R2-NS-NV-00 | 531X126SNDACG1 | F31X187VCTABG1 |

| F43HENA-R4-NS-NV-00 | 531X126SNDABG1 | F31X185lPTAHG1 |

| F43HENA-R2-NS-NV-00 | 531X126SNDAAG2 | F31X184lPTADG1 |

| F43HEMA-R4-KS-NV-00 | 531X126SNDAAG1 | F31X175SSBAKG2 |

| F43GENA-R2-NS-NV-00 | 531X125SNHAFG2 | F31X175SSBADG1 |

| F43GENA-R2-NS-NG-00 | 531X125SNHAFG1 | F31X175SSBABG1 |