Home > Product > DCS control system > MSK060C-0300-N N-S1-UP0-NNNN servo motor

MSK060C-0300-N N-S1-UP0-NNNN servo motor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MSK060C-0300-N N-S1-UP0-NNNN

- Get the latest price:Click to consult

MSK060C-0300-N N-S1-UP0-NNNN servo motor

Product Details Introduction

Ensure that the motor is coaxial with the load during installation to reduce radial force damage to the MSK060C-0300-NN-S1-UP0-NNNN shaft end.

Be sure to hold the motor body during transportation, and do not grip the encoder or cable to avoid damaging the signal interface of MSK060C-0300-NN-S1-UP0-NNNN.

MSK060C-0300-NN-S1-UP0-NNNN supports three loop control of position, speed, and torque, and is suitable for precision machine tools and other scenarios.

When wiring, VDE certification tools should be used, and attention should be paid to the bending radius of the cable to avoid line faults affecting motor operation.

Regularly clean the encoder and heat dissipation fins, MSK060C-0300-NN-S1-UP0-NNNN relies on natural heat dissipation to ensure performance.

Although equipped with IP65 protection, it is still necessary to ensure that the operating environment temperature of MSK060C-0300-NN-S1-UP0-NNNN is between 0-40 ℃.

This model is designed with maintenance free bearings and does not require additional lubricating grease to avoid unauthorized disassembly and affecting the seal.

If there is abnormal noise during operation, stop the machine immediately and check if it exceeds the maximum torque limit of 24Nm for MSK060C-0300-NN-S1-UP0-NNNN.

When disassembling the coupling components, it is forbidden to strike the shaft end. The MSK060C-0300-NN-S1-UP0-NNNN shaft end with DIN standard keyway needs special protection.

Regularly check the connection between the wiring terminal and the protective conductor to ensure that MSK060C-0300-NN-S1-UP0-NNNN is firmly grounded.

Avoid applying axial loads exceeding the specified limits to prevent damage to the motor bearings and internal transmission structure.

If the supporting cable is damaged, it should be replaced immediately and cannot be repaired temporarily to avoid affecting the insulation performance of the motor.

When adjusting PID parameters, the positioning accuracy can be optimized by combining the encoder resolution of MSK060C-0300-NN-S1-UP0-NNNN.

When connecting external devices, it is necessary to install oil seals to prevent oil contamination from entering the interior of the motor and causing component corrosion.

After being idle for a long time and restarting, it is necessary to first test the insulation and confirm that there are no abnormalities before gradually running at the rated speed.

Summary: The stable operation of MSK060C-0300-NN-S1-UP0-NNNN servo motor needs to take into account both general specifications and exclusive characteristics, with a focus on protection level adaptation, encoder protection, load torque control, and compliance maintenance, fully leveraging its precision control and high reliability advantages to extend the service life of the entire machine.

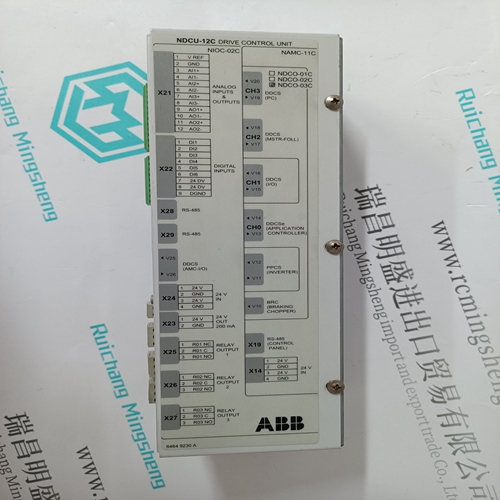

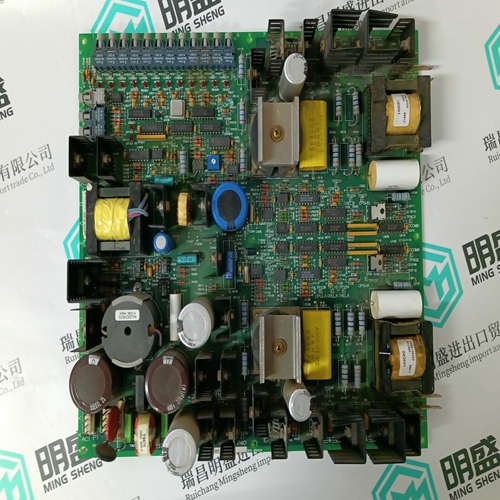

MSK060C-0300-N N-S1-UP0-NNNN Product imag

MSK060C-0300-N N-S1-UP0-NNNN ontroller Module

GE SR750-P5-G5-S5-HI-A20-R-T Power protection relay

SR750-P5-G5-S5-HI-A20-R-T Relay shell

033.733.002.S Dc channel CARDS

Other website links

Bently 149992-01 继电器模块

Motorola MVME2400-0361 单板计算机

Woodward 8290-185速度控制器

| F45FENA-R2-NS-VS-00 | 531X126SNDADG1 | F31X187VCTACG1 |

| F45FENA-R2-NS-NV-00 | 531X126SNDACG1 | F31X187VCTABG1 |

| F43HENA-R4-NS-NV-00 | 531X126SNDABG1 | F31X185lPTAHG1 |

| F43HENA-R2-NS-NV-00 | 531X126SNDAAG2 | F31X184lPTADG1 |

| F43HEMA-R4-KS-NV-00 | 531X126SNDAAG1 | F31X175SSBAKG2 |

| F43GENA-R2-NS-NV-00 | 531X125SNHAFG2 | F31X175SSBADG1 |

| F43GENA-R2-NS-NG-00 | 531X125SNHAFG1 | F31X175SSBABG1 |