Home > Product > Gas turbine system > FBM237-P0917QZ output module

FBM237-P0917QZ output module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:FBM237-P0917QZ

- Get the latest price:Click to consult

Product Details Introduction

Application Fields of FBM237-P0917QZ Output Module

The FBM237-P0917QZ output module is a Foxboro I/A series analog output module with an 8-channel independent isolation design. It supports 4-20mA DC analog output and redundant configuration, and can withstand a wide temperature range of -20 ℃ to+70 ℃ and harsh industrial environments. It is compatible with the HART protocol and can accurately drive actuators to achieve closed-loop control of process parameters. It is suitable for automation scenarios in multiple industries. The specific applications are as follows:

1. Petrochemical distillation unit: Output precise current signals to control the opening of regulating valves, adjust material flow and temperature, and rely on redundant design to ensure continuous production.

2. Thermal power boiler system: Drive the feedwater control valve and induced draft fan actuator to accurately regulate the water level and air volume, adapting to the high reliability requirements of power plants.

3. Urban sewage treatment plant: Control the operation of aeration valves and dosing pumps, dynamically adjust the output according to water quality parameters, and optimize sewage treatment efficiency.

4. Pharmaceutical industry reaction kettle: Adjust the stirring speed and cooling valve opening according to the process curve to comply with GMP standards and ensure batch production consistency.

5. Metallurgical continuous casting production line: Drive the crystallizer liquid level regulating valve, accurately control the liquid level of molten steel, and adapt to high temperature and strong interference industrial environments.

6. Food and beverage filling line: Control the flow regulating valve and filling valve to achieve quantitative filling, relying on high-precision output to ensure uniform product specifications.

7. Natural gas long-distance pipelines: Adjust pressure regulating valves and shut-off valves to respond in real-time to pressure changes, ensuring safe and stable pipeline transportation.

8. Cement rotary kiln system: drives the feeder and coal injection actuator to regulate the temperature and material ratio inside the kiln, reducing energy consumption.

9. Semiconductor clean room: Control the fresh air valve and pressure regulating valve to maintain constant temperature and pressure in the workshop, and adapt to the requirements of cleanliness control.

10. Seawater desalination equipment: Adjust the pressure regulating valve of the reverse osmosis membrane to optimize water production efficiency and withstand high salt spray corrosion environments.

11. Rubber vulcanization production line: Control steam valves and hydraulic actuators, accurately regulate vulcanization temperature and pressure, and improve product quality.

12. Urban centralized heating pipeline network: Adjust the water supply regulating valve of the heat exchange station, dynamically adjust the heating amount according to the outdoor temperature, and achieve energy-saving operation.

13. Lithium battery material mixing equipment: Control the speed of the mixing motor and the feeding valve to ensure the uniformity of material mixing and adapt to the production conditions of lithium batteries.

14. Industrial kiln temperature control system: Drive the gas regulating valve to accurately control the temperature inside the furnace according to the heating curve, suitable for high-temperature industrial scenarios.

15. Mining flotation workshop: Adjust the reagent addition pump and flotation machine level valve to optimize mineral flotation efficiency and withstand dust interference environment.

Note: The core advantages of the product are multi-channel isolation, redundant fault tolerance, and high environmental adaptability. It supports fault safe action configuration, is compatible with Foxboro DCS system, and adapts to various industrial process closed-loop control requirements.

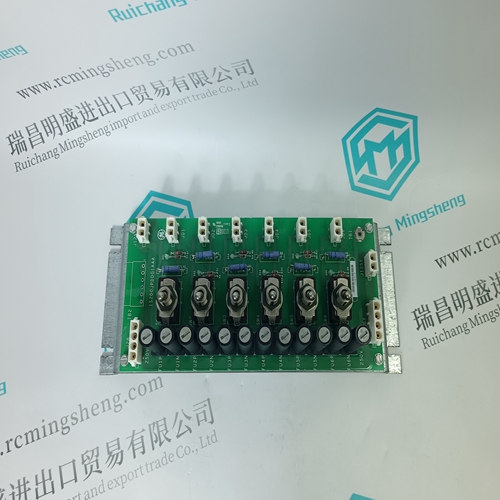

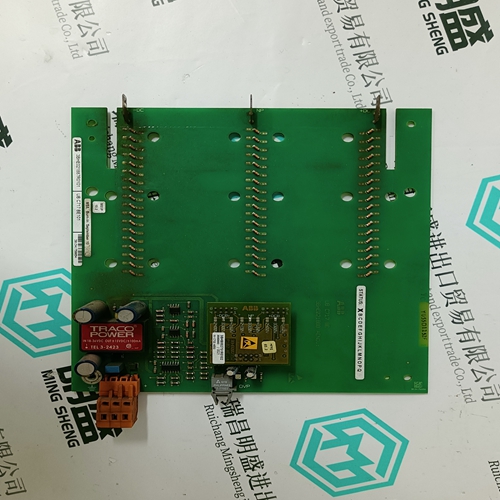

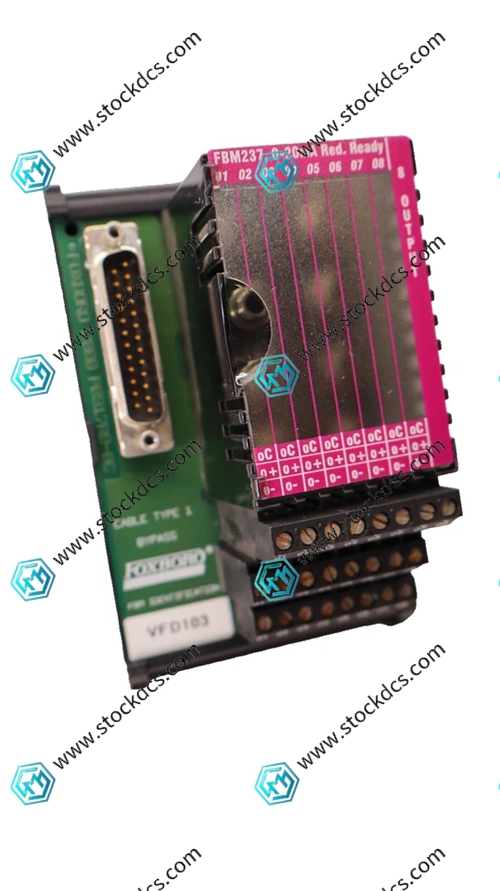

FBM237-P0917QZ Product imag

FBM237-P0917QZ ontroller Module

FOXBORO FBM204 processor module

Woodward 8273-140 2301D speed controller

B&R 8LSA46.R0045D000-0 servo motor

Other website links

UNS 0121A-Z,V1 UN1010-0001自动电压调节器

UNITROL 1010 3BHE035301R1002多功能控制器

NI SCXI-1324多通道数据采集模块

| 33VM62-000-75 | 3090-SCCT083 | IC3600VLEB1A |

| 33VM62-000-21 | 3090-SCCT063 | IC3600VLEA1 |

| 33VM62-000-17 | 3090-SCCT043 | IC3600VDAC1C |

| 33VM62-000-1 | IC3600VDAC1 | |

| 33VM52-020-9 | 3090-SCCT022 | IC3600VCDA1 |

| 33VM52-008-4 | 3090-RTM-317 | IC3600VBEA1 |

| 33VM52-000-4 | 3090-MCI101 | IC3600VBCU1B |

| 33VM52-000-29 | 3090-CAB108 | IC3600VBCU1 |