Home > Product > Robot control system > 853-286086-100 Multi frequency Controller

853-286086-100 Multi frequency Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:853-286086-100

- Get the latest price:Click to consult

853-286086-100 Multi frequency Controller

Product Details Introduction

853-286086-100 Multi frequency Controller Description

853-286086-100 is an industrial grade multi frequency controller suitable for high-precision welding control scenarios in resistance welding

2. Supports multi band switching, covering modes such as mid frequency and high-frequency pulses, and adapts to the welding needs of multiple materials

3. With precise heat input control, it can reduce welding spatter and adapt to welding of thin plates and coating materials

4. Working temperature range -10 ℃ to 55 ℃, suitable for conventional industrial workshop welding environment

5. Support preheating, main welding, and tempering multi-stage welding modes to reduce welding stress

6. Equipped with intelligent recognition of load characteristics, it can automatically recommend the optimal frequency and energy output mode

7. Equipped with communication interfaces such as Modbus and EtherCAT, it can seamlessly integrate with PLCs and robots

8. Support real-time monitoring of welding parameters, automatic adjustment or shutdown protection in case of abnormalities

9. Store multiple sets of process parameter templates, which can quickly switch and adapt to different batch production needs

10. High frequency inverter module design, high energy conversion efficiency, low energy consumption, more energy-efficient and environmentally friendly

11. Onboard multi state indicator light, providing real-time feedback on abnormal operation, communication, and welding status

12. Modular structure design, easy installation and maintenance, suitable for automated production line layout

13. Professional personnel are required for installation and debugging, strictly following the welding process parameter configuration specifications

14. Smoking is strictly prohibited in the welding operation area, fire extinguishing equipment must be equipped, and fire and explosion prevention measures must be taken

15. The factory has undergone full process testing for electrical performance, welding accuracy, etc., and meets industrial quality standards

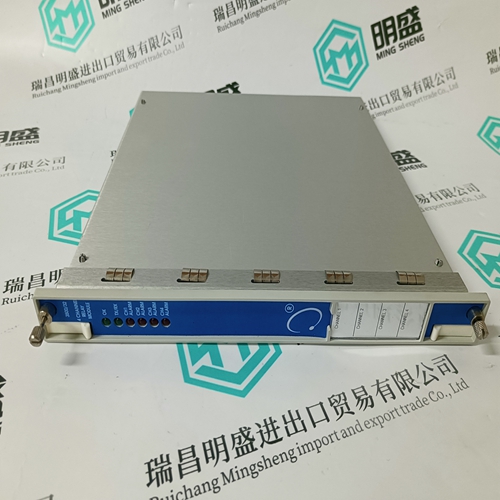

853-286086-100 Product imag

853-286086-100 ontroller Module

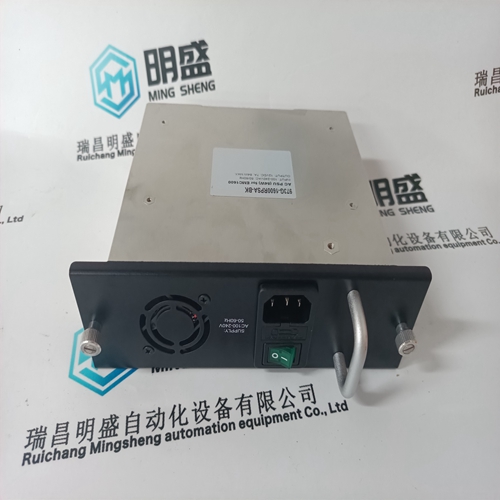

CISCO IE-4000-16GT4G-E switches

IS200TBCIS2CCD Gas turbine module

IS230TCISH6C Gas turbine module

Other website links

TRICONEX 3625C1数字量输出模块

IC693PWR322F模拟量扩展模块

FOXBORO FBM230 P0926GU现场控制处理器

| IC3600SFUA1C | 6DD1682-0BC3 | IC3600SSVD1 |

| IC3600SFUA1 | 6DD1682-0BC0 | IC3600SSVB1B |

| IC3600SFPB1B1C | 6DD1683-0CC0 | IC3600SSVB1 |

| IC3600SFPB1B | 6DD1683-0BE5 | IC3600SSVA1F1C |

| IC3600SFPB1 | 6SC6504-0AF01 | IC3600SSVA1 |

| IC3600SFKK1 | 531X300CCHALM3 | IC3600SSLD1H1D |

| IC3600SFKD1C | IC3600SSLD1F1B | |

| IC3600SFKD1 | 531X300CCHAJM2 | IC3600SSLD1E |