Home > Product > Servo control system > 244-INWW digital instrument measurement system

244-INWW digital instrument measurement system

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:244-INWW

- Get the latest price:Click to consult

244-INWW digital instrument measurement system

Product Details Introduction

244-INWW is an industrial grade integrated digital instrument measurement system that integrates multi parameter acquisition, precise measurement, data transmission, and intelligent control functions. It is designed for scenarios such as power, chemical, and liquid hydrocarbon filling, and is suitable for the full process measurement needs from on-site detection to backend settlement. Its core features are as follows:

1. Multi parameter precise measurement

Support synchronous acquisition of multiple parameters including flow rate, pressure, temperature, and density, with a measurement accuracy of ± 0.1% FS. Standard measurement can be achieved without the need for additional compensation modules, effectively reducing supply and sales differences and ensuring measurement fairness and accuracy.

2. Full process data closed-loop control

Build a closed-loop system of "on-site inspection data transmission backend analysis settlement archiving", which can seamlessly integrate with MES and ERP systems, achieve automatic uploading of measurement data, intelligent business settlement, and reduce manual input errors.

3. Multi protocol compatible communication

Native support for Modbus RTU, Profinet, and Ethernet communication protocols, can be linked with DCS systems, intelligent instruments, and batch controllers to achieve remote monitoring, parameter configuration, and command issuance, and is compatible with distributed control architectures.

4. Multiple safety interlock protection

Integrated safety interlock functions such as anti-static grounding, overpressure and overcurrent, liquid level switch, etc., automatically stop measuring and trigger alarms under abnormal working conditions, while recording fault information to ensure on-site operation safety and avoid the expansion of accidents.

5. Intelligent reporting and data traceability

Automatically generate class, daily, and monthly statistical reports, support filtering and querying by material, time, workstation, and other conditions, with a historical data storage capacity of over 1 million records and a data traceability period of over 3 years, meeting compliance audit requirements.

6. Permission grading and operation tracking

Adopting a three-level permission management mechanism (administrator, operator, observer), all key operations require password verification, and operation records are automatically saved and cannot be tampered with, facilitating responsibility tracing and process control.

244-INWW Product imag

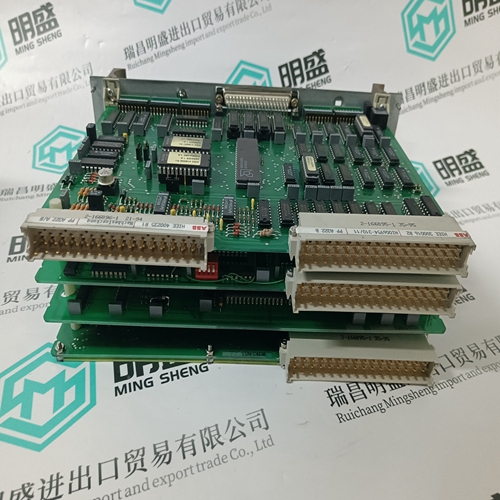

244-INWW ontroller Module

DATX110 3BSC980004R784 control card

AD908AC Output structure module

AD908AE structure cable

Other website links

HVC-02B 3HNA024966-00103机器人卡件模块

Schneider BMEP585040以太网模块

ACU-01B 3HNA024871-00102机器人控制器

| PMB31B-10214-01 | AMAT 0100-03267 | 57160001-BN DSTD 151 |

| PMB31B-10214-00 | NTAI05 | M22NRXC-LDN-M1-00 |

| PMB31B-10201-03 | AMAT 0100-76085 | PFVL141R |

| PMB31B-10201-02 | INIIT02 | 57120001-NY DSTA 121 |

| PMB31B-10201-01 | FPR3315101R1032 | 57160001-NB DSTD 115 |

| PMB31B-10201-00 | PHBDIO4000R100 | XV 7718b |

| PMB31B-10200-03 | AMAT 0100-00208 | P21NRXB-LNF-NS-00 |