Home > Product > PLC programmable module > 810-048219-008 Input/Output Module

810-048219-008 Input/Output Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:810-048219-008

- Get the latest price:Click to consult

810-048219-008 Input/Output Module

Product Details Introduction

810-048219-008 Input/Output Module Product Application Fields

1. Control of electronic component production line: Collect operation signals of surface mount machines and welding machines, drive conveying and positioning mechanisms, and achieve precision assembly coordination.

2. Pharmaceutical workshop automation: Collect temperature, humidity, and pressure difference signals in the clean area, control fresh air and disinfection mechanisms, and comply with GMP production standards.

3. Intelligent warehouse sorting system: Receive barcode recognition signals, control the action of sorting robotic arms, and improve the accuracy of goods sorting.

4. Industrial wastewater treatment system: Collect COD, ammonia nitrogen and other water quality signals, adjust the dosing pump and aeration equipment to ensure that the effluent meets the standard.

5. Die casting equipment control: Collect mold pressure and temperature signals, control the opening and closing actions of the die casting machine, and improve the quality of castings.

6. Building control of commercial complexes: Collecting fire and security signals, linking lighting and smoke exhaust equipment to ensure emergency response of buildings.

7. Energy storage station management: Collect battery voltage and temperature signals, execute charge and discharge control instructions, and ensure the safe operation of the energy storage system.

8. Label printing equipment: Collect the positioning signal of the printing plate roller, control the ink supply and drying mechanism, and ensure the clarity of label printing.

9. Tunnel construction equipment monitoring: Collect the operation status signals of shield tunneling machines, control the propulsion and support mechanisms, and ensure the safety of tunnel construction.

10. In vitro diagnostic equipment control: Collect and detect sample signals, control reagent dispensing and testing mechanisms, and ensure accurate diagnostic results.

11. Non woven fabric production equipment: Collect fiber tension and web thickness signals, control the rolling mill and winding mechanism, and ensure stable non-woven fabric quality.

12. Smart grid distribution network monitoring: Collect distribution network current and voltage signals, execute load adjustment instructions, and ensure stable distribution network power supply.

13. Greenhouse automation: Collect soil temperature, humidity, and light signals, control irrigation and shading mechanisms, and optimize crop growth environments.

14. Stereoscopic garage control system: collects parking space occupancy signals, controls the lifting and translation mechanisms, and ensures safe and efficient vehicle access.

15. Automation Control Training Platform: Provides signal acquisition and command output simulation for vocational education training, supporting skills training.

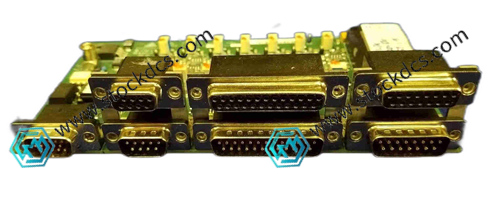

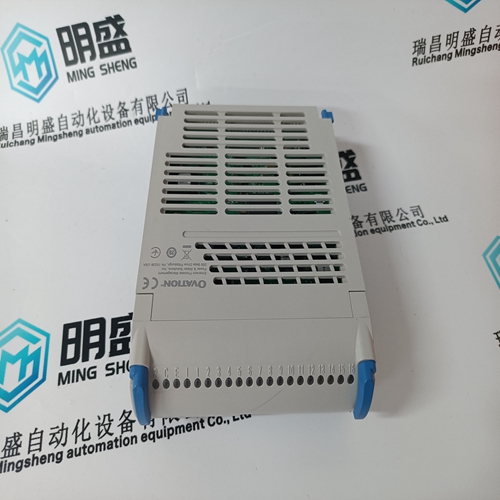

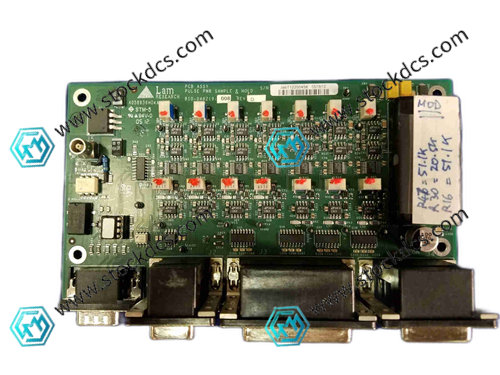

810-048219-008 Product imag

810-048219-008 ontroller Module

KUC321AE HIEE300698R0001 Control module

PPC905AE101 3BHE014070R0101 3BHE014071P201 module

SA811F 3BDH000013R1 Logic output module

Other website links

CS513 3BSE000435R1局域网模块

3BSE014666R1 CI541V1通讯卡模块

CI535V30 3BSE022162R1总线控制模块

| 6ES5095-8MA05 | CACR-SR15SZ1SD-Y77 | 8101-HI-TX-02 |

| 6ES5095-8MA01 | 6SC9311-2GF25 | LDSYN-101 |

| 6ES5090-8MA01 | CACR-SR10SB1AF | 6ES5521-8MA22 |

| 6ES308-3UC11 | CACR-JU102A2A | PPC905AE101 |

| 6DD2920-0AW2 | 6SC6108-0SE01 | V18345-1010521001 |

| 6DD2920-0AW1 | CACR-SR20SB1BF | SCYC51010 |

| 6DD2920-0AW0 | CACR-SR30SBBFY100 | 3BHB003688R0101 |