Home > Product > Gas turbine system > 61234-KEGQ-AWX Butterfly Valve Control System

61234-KEGQ-AWX Butterfly Valve Control System

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:61234-KEGQ-AWX

- Get the latest price:Click to consult

61234-KEGQ-AWX Butterfly Valve Control System

Product Details Introduction

61234-KEGQ-AWX Butterfly Valve Control System Product Features

1. Integrated intelligent control design, integrated drive execution and monitoring module, realizing full process automation control of butterfly valve, suitable for industrial fluid systems such as chemical, water treatment, energy, etc

2. Adopting high-precision servo drive technology, the valve opening adjustment accuracy reaches ± 0.5%, with a resolution of 0.1 °, which can achieve fine control of flow rate

3. Excellent response speed, with a full travel opening and closing time of ≤ 3 seconds and an emergency cut-off response time of ≤ 0.5 seconds, suitable for rapid control needs in emergency working conditions

4. Support PID closed-loop automatic adjustment, which can dynamically adjust valve opening according to preset flow and pressure parameters without manual intervention, ensuring system operation stability

5. Built in multi parameter monitoring module, real-time collection of valve opening, medium flow/pressure/temperature, and motor operation status, with a data sampling frequency of 50Hz

6. Equipped with fault self diagnosis function, it can identify faults such as valve stem jamming, seal wear, sensor abnormalities, etc., generate fault codes, and push repair suggestions

7. Support multi-mode control switching, covering remote central control, local manual control, timed control, and scene linkage, adapting to different automation management needs

9. The protection level of the actuator reaches IP67, supporting Ex d Ⅱ CT6 explosion-proof design, and can operate stably for a long time in harsh industrial environments such as humidity, dust, flammability, and explosiveness

10. Equipped with high-definition local display screen, visually presenting operating parameters and status information, while supporting historical data storage and traceability, with a storage capacity of ≥ 100000 records

11. Equipped with a fail safe mode, it can automatically reset to the preset safe position (fully open/fully closed) when the gas/power supply is interrupted, reducing the risk of accidents

12. The valve body adopts a multi-level sealing structure, with a leakage level of ANSI B16.104 Class VI, almost zero leakage, suitable for high cleanliness and high-risk medium control scenarios

13. Modular structure design, supporting online replacement of seals and actuators, easy maintenance, significantly reducing downtime for maintenance

14. Suitable for a wide range of working conditions, with a temperature resistance of -40 ℃ to 300 ℃ and a pressure resistance level of PN16-PN42, it can be matched with pipeline systems of different media and pressure levels

15. Mechanical lifespan ≥ 100000 cycles of operation, mean time between failures (MTBF) ≥ 5000 hours, high operational reliability, and low maintenance costs

16. Support functional module expansion, which can add explosion-proof, traffic measurement, blockchain traceability and other modules as needed to adapt to special scenario requirements

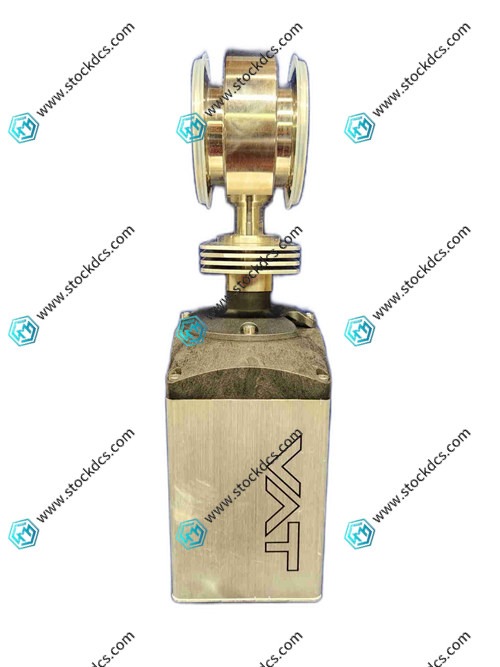

61234-KEGQ-AWX Product imag

61234-KEGQ-AWX ontroller Module

PMC-6130-J 0100RSDPMC-J Measure the voltage module

NI SCXI-1125 Measure the voltage module

UNITROL 1010 3BHE035301R1002 UNS0121A-Z,V1 module

Other website links

PU519 3BSE018681R1控制器模块

PM891 3BSE053240R1分布式控制系统

PFSK142 3BSE006505R1机器人驱动模块

| IC3600SCBE1A | 531X300CCHAAM5 | IC3600SSFG1B1B |

| IC3600SCBE1 | 531X300CCHAAFM5 | IC3600SSFG1B1A |

| IC3600SCBD4A | 531X221KLDADG1 | IC3600SSFG1A |

| IC3600SCBD4 | 531X213D10ABG1 | IC3600SSFG1 |

| IC3600SCBD3A | 531X213D10AAG1 | IC3600SQIC1 |

| IC3600SCBD3 | 531X212DPCABG1 | IC3600SQIA1 |

| IC3600SCBD2A | 531X212DPCAAG1 | IC3600SPSV1 |