Home > Product > Servo control system > 1407-7017-000 Flow Sensor

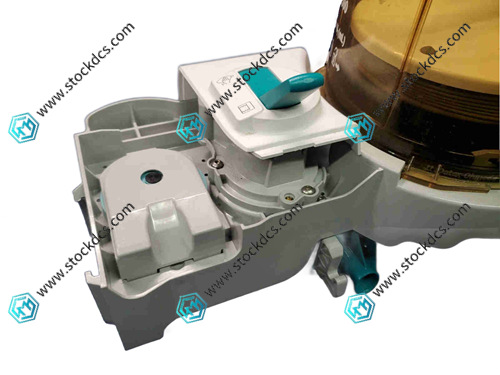

1407-7017-000 Flow Sensor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1407-7017-000

- Get the latest price:Click to consult

Product Details Introduction

1407-7017-000 Flow Sensor Related Instructions

1407-7017-000 is an industrial grade high-precision flow sensor, with the core function of real-time detection of fluid (liquid/gas) flow and output standard signals, suitable for industrial process monitoring scenarios such as chemical engineering, water treatment, and energy

2. Adopting the vortex street measurement principle, detection can be completed without contact with fluids, with strong anti pollution ability and adaptability to various media types

3. The measurement accuracy reaches ± 1.5% FS, with excellent repeatability and stable output of accurate flow data, ensuring the reliability of process control

4. Support wide flow range measurement, covering low, medium, and high gradient flow requirements, and adapting to different working conditions and scenarios

5. The working temperature range is -20 ℃ to 120 ℃, and the working pressure is suitable for industrial conventional pressure levels, with strong environmental adaptability

6. Output 4-20mA standard analog signal, which can be directly connected to industrial control systems such as PLC and DCS, with stable signal transmission

7. Built in temperature compensation module, which can automatically correct the impact of temperature changes on measurement accuracy and improve data accuracy

8. The sensor probe is made of stainless steel material, which is corrosion-resistant, wear-resistant, and suitable for harsh industrial fluid environments

9. Supports RS-485 digital communication, compatible with Modbus RTU protocol, capable of remote traffic monitoring and parameter configuration

10. Equipped with abnormal traffic alarm function, it automatically triggers a signal when the traffic exceeds the set threshold, reminding staff to handle it

11. Adopting flange installation design, precise positioning, excellent sealing performance, can effectively prevent fluid leakage

Before installation, it is necessary to check the matching between the sensor model and the pipeline diameter to ensure that the installation direction meets the requirements of fluid flow direction

13. Debugging and calibration must be operated by professionals, and the calibration cycle must follow the industrial instrument maintenance standards

14. Do not use in environments with excessive temperature, pressure, or strong corrosion to avoid damaging sensor probes and internal electronic components

15. The factory has undergone full process verification including precision calibration, sealing testing, and environmental adaptability testing, and meets the quality standards of industrial flow meters

1407-7017-000 Product imag

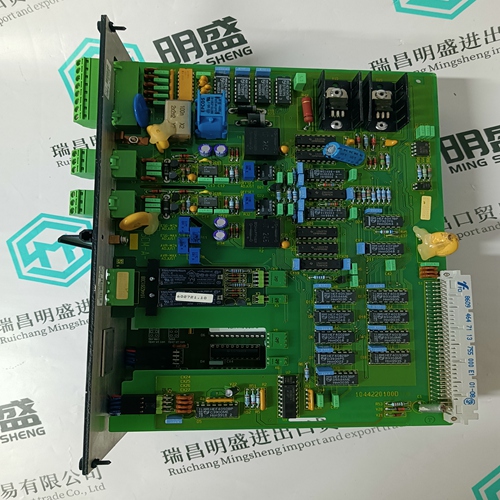

1407-7017-000 ontroller Module

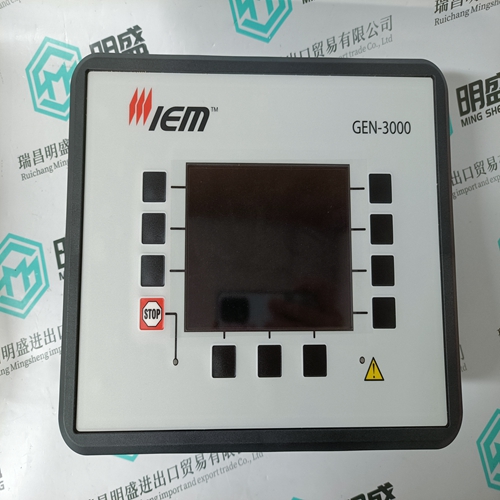

SAIA PCD2.M48X Analog module sequence

PMC-6130-J 0100RSDPMC-J Measure the voltage module

NI SCXI-1125 Measure the voltage module

Other website links

EPRO MMS6110控制卡

CSH01.1C-SE-EN2-NNN-NNN-NN-S-XP-FW驱动器

EMERSON 1C31166G01模拟输入模块

| IC3600SCBN2A | 531X300CCHAEM2 | IC3600SSKC1 |

| IC3600SCBN1B | 531X300CCHADM5 | IC3600SSKB1 |

| IC3600SCBN1 | 531X300CCHADM3 | IC3600SSKA1G1C |

| IC3600SCBM2 | 531X300CCHADM2 | IC3600SSKA1F |

| IC3600SCBL1 | 531X300CCHADM1 | IC3600SSKA1 |

| IC3600SCBK1 | 531X300CCHACM1 | IC3600SSIB1 |

| IC3600SCBH1 | 531X300CCHABM5 | IC3600SSIA1 |