Home > Product > Robot control system > 0190-49895 Digital Mass Flow Controller

0190-49895 Digital Mass Flow Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:0190-49895

- Get the latest price:Click to consult

0190-49895 Digital Mass Flow Controller

Product Details Introduction

0190-49895 Description of Digital Mass Flow Controller

0190-49895 is an industrial grade digital quality flow controller, suitable for precise gas flow control scenarios

2. Adopting the principle of thermal measurement, directly measuring gas mass flow rate without temperature and pressure compensation

3. High control accuracy, with an accuracy of ± 0.25% FS and excellent repeatability, ensuring stable flow

4. Working temperature range: 0 ℃ to 50 ℃, suitable for conventional industrial and laboratory environments

5. The control range covers 3-100% of the full range and is suitable for multi flow gradient control requirements

6. Supports 4-20mA, 0-5VDC analog signal output, compatible with mainstream control systems

7. Fast response speed, with a response time of less than 1 second, can quickly provide feedback on changes in traffic and adjust accordingly

8. Made of corrosion-resistant materials, compatible with various commonly used industrial gases such as nitrogen and argon

9. Supports RS-485 digital communication, compatible with standard communication protocols, and can be remotely monitored and configured

10. Compatible with+15~+24VDC power supply, stable power connection, strong resistance to voltage fluctuations

11. Onboard status indicator light, providing real-time feedback on operation, faults, and flow signal status

12. Standardized installation design, compatible with multiple pipeline interfaces, easy installation and maintenance

13. Overpressure use is prohibited, and gas medium compatibility and pipeline sealing must be checked before installation

14. Debugging requires professional personnel to operate, and before zero point calibration, it is necessary to ensure that there is no gas leakage in the pipeline

15. The factory has undergone full process testing such as precision calibration and leakage detection, and meets industrial quality standards

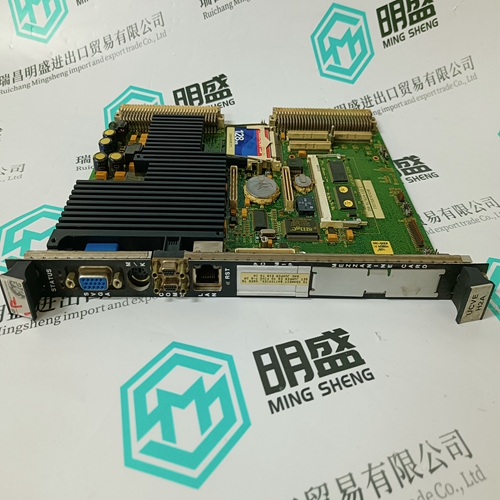

0190-49895 Product imag

0190-49895 ontroller Module

HVC-02B 3HNA024966-00103 Pulse logic module

CISCO IE-4000-16GT4G-E switches

IS200TBCIS2CCD Gas turbine module

Other website links

FOXBORO FBM230 P0926GU现场控制处理器模块

TRICONEX 3625C1数字量输出模块

IC693PWR322F模拟量扩展模块

| IC3600SGDE1 | 6DD1682-0CG0 | IC3600SSZA1 |

| IC3600SGDD1A1 | 6DD1682-0CF0 | IC3600SSVJ1 |

| IC3600SGDD1 | 6DD1682-0CE4 | IC3600SSVG1 |

| IC3600SGDA1 | 6DD1682-0CE3 | IC3600SSVF1B |

| IC3600SFVA1 | 6DD1682-0CD0 | IC3600SSVF1 |

| IC3600SFUC1B | 6DD1682-0CC0 | IC3600SSVE1 |

| IC3600SFUC1 | 6DD1682-0BE0 | IC3600SSVD1J1B |

| IC3600SFUB1 | 6DD1682-0BC4 | IC3600SSVD1H |