Home > Product > Servo control system > ER-JD7200D CNC motor encoder

ER-JD7200D CNC motor encoder

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ER-JD7200D

- Get the latest price:Click to consult

Product Details Introduction

The OKUMA ER-JD7200D is equipped with a 24 bit high-resolution BL series servo motor and is paired with the same series ER-MJ-7200D (ATC magazine specific) to meet the grading positioning and tool magazine linkage requirements of CNC lathes.

As a classic model of absolute encoder, ER-JD7200D supports power-off zero free function. This core configuration is shared with ABS-FB-D2048 (2048PPR basic model) and is suitable for precision position feedback scenarios of OSP 5000 system.

The industrial grade sturdy shell design enables the ER-JD7200D to withstand vibration and impact, and in conjunction with the ER-M-SD (IP65 protection), covers different protection requirements from conventional workshops to humid conditions.

In high-speed turret control, the optical sensing technology of ER-JD7200D ensures signal stability, while the ER-MJ-7200D (5kHz signal adaptation version) is more suitable for high-precision feedback of hydraulic drive equipment, ensuring safety and reliability.

With the help of multiple protocol output interfaces, the ER-JD7200D can quickly integrate with Okuma CNC systems, and this compatibility is consistent with the ER-J-7200D (Universal Absolute Encoder), simplifying the equipment debugging process.

In the CNC milling machine processing scenario, the ER-JD7200D's 0.0001mm positioning accuracy is suitable for complex workpiece processing, and when paired with ABS-FB-D2048 (economical), it achieves precise control from mass production to customized processing.

As a servo specific encoder, the ER-JD7200D is compatible with BLID and BLD series motors, and this advantage is shared with the ER-M-SD (stainless steel shell version) to enhance the flexibility of heavy-duty equipment selection.

In electronic component processing equipment, the low-power design of the ER-JD7200D saves energy and complements the ER-J-7200D (compact) to meet the precise fine-tuning needs of high-speed operation.

OKUMA ER-JD7200D supports wide temperature range of -20~70 ℃, with unified operation logic with ER-MJ-7200D (multi cycle measurement model), reducing maintenance costs of multi device linkage and improving production line attendance.

In the CNC machining scenario of new energy equipment, the axis mounted design of ER-JD7200D simplifies installation and, together with ER-M-SD (panel mounted version), covers the full range of position feedback requirements from lightweight machine tools to heavy-duty units.

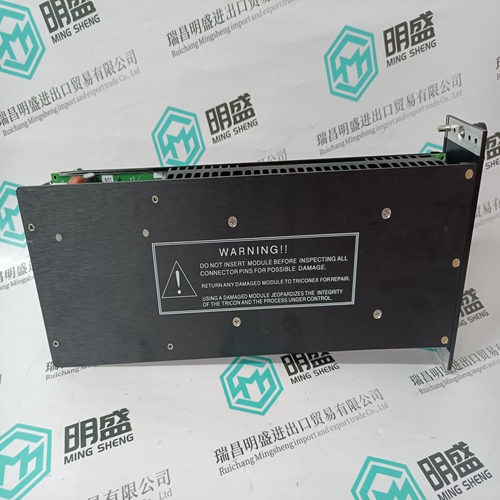

ER-JD7200D Product imag

ER-JD7200D ontroller Module

KONGSBERG RMP201-8 ship controller

RH924UQ Field bus module

SPHSS03 signal processing card

Other website links

DSDP140B 57160001-ACX 远程输入/输出基本单元

VMIVME-7650-83H 电源模块

TRICONEX 8305A分散型控制系统

| 6DD1660-0AD0 | 6SC9311-3FK15 | PFTL101B 2.0KN |

| 6DD1645-0AF2 | CACR-IR050505FD | 6ES5497-4UD11 |

| 6DD1645-0AE1 | CACR-HR01BAB11Y11 | UFC718AE101 |

| 6DD1645-0AE0 | CACR-SR20BE13FY8 | 6ES5135-3KA13 |

| 6DD1642-0BC0 | CACR-IR44SC1 | 6ES5431-8MD11 |

| 6DD1641-0AC0 | 6SC9311-2GJ15 | 751010R0815 |