Home > Product > Servo control system > PCA-100 Printed Circuit Components

PCA-100 Printed Circuit Components

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PCA-100

- Get the latest price:Click to consult

PCA-100 Printed Circuit Components

Product Details Introduction

PCA-100 Printed Circuit Assembly (PCBA) Product Features and Instructions

1、 Product Overview and Core Features

PCA-100 is an industrial grade high-performance printed circuit assembly (PCBA) that is suitable for scenarios such as instrumentation, communication equipment, and medical electronics. Its core features include high integration process design, SMT/THT hybrid packaging components, and a balance between precision and stability; Has excellent resistance to electromagnetic interference and supports synchronous transmission of multiple signals; Adopting environmentally friendly lead-free technology, meeting industrial safety standards, reliable operation, and adapting to customized needs.

2、 Core parameters

-Core configuration: using FR-4 or low loss substrate, copper foil thickness ≥ 1 ounce, supporting multi-layer wiring, minimum line width/spacing ≥ 0.1mm.

-Performance: Impedance control accuracy ± 5%, solder resistance 280-360 ℃, built-in filtering structure, low noise, low signal attenuation, in compliance with EMC standards.

-Installation: Compatible with built-in fixed devices, compatible with automated assembly, supports pin and surface mount component linkage, and facilitates system integration.

3、 Working principle

As the core carrier of the circuit, signal interaction and energy transmission between onboard components are achieved through precise pre-set circuit layout. By relying on high-quality substrates and optimized processes for rapid heat dissipation, local overheating losses are reduced. At the same time, shielding design is used to resist external interference, ensuring stable synchronous transmission of multiple signals. After rigorous testing and verification, it is suitable for long-term operation in complex industrial environments.

4、 Key points for installation and debugging

-Installation: Keep the board clean and free of dust and oil stains, strictly control the welding temperature to prevent deformation of the substrate, handle gently to avoid damage to the circuit and solder joints, and fix it in a standardized manner to avoid vibration effects.

-Debugging: Check the integrity of solder joints, circuit conductivity, and impedance matching, test the stability of signal transmission, and identify hidden dangers of short circuits and virtual soldering.

5、 Safety maintenance and troubleshooting

-Safety: Anti static wristbands must be worn during operation to avoid electrostatic breakdown of components. Contact with corrosive solvents is prohibited, and insulation protection should be taken after welding.

-Maintenance: Regularly clean the dust on the board surface, inspect the oxidation of solder joints and aging of circuits, and review the insulation performance and signal transmission quality.

-Fault: Check impedance matching and interference source for abnormal signal, check solder joint virtual soldering/insulation damage for short circuit, check heat dissipation and copper foil circuit for abnormal heating.

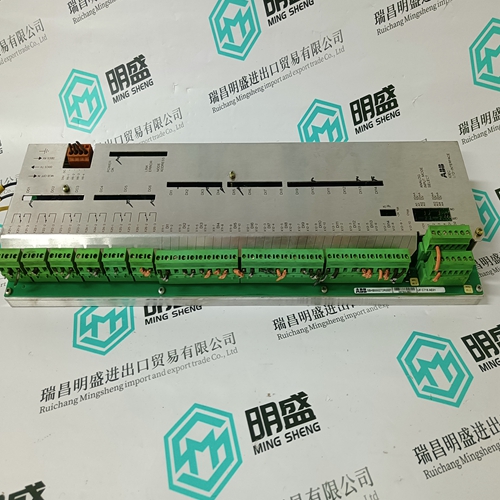

PCA-100 Product imag

PCA-100 ontroller Module

GE IS200VAICH1DAB Gas turbine electric

GE IS200VCRCH1BBC Gas turbine electrical module

GE IS200VRTDH1DAB Gas turbine electric card

Other website links

IC698CPE040数字量扩展模块

BENTLY 190027振动监测器

TRICOEX 9300 9852 9852自动化模块

| K42HLFK-LNK-NS-00 | AMAT 0100-09220 | INTKM01 |

| K42HCHM-LNK-NS-00 | AMAT 0100-91119 | INICT13A |

| K34HRHJ-LNK-NS-00 | AMAT 0100-00579 | IMSED01 |

| K33SRFJ-LSS-N2-02 | AMAT 0100-00379 | IMSET01 |

| K33HRFG-LNK-NS-00 | AMAT 0100-71275 | IMCPM02 |

| K33HLHM-LNK-NS-00 | AMAT 0100-40029 | INSEM01 |

| K33HLHJ-LNK-NS-01 | AMAT 0100-14006 | INICT12 |