Home > Product > Robot control system > 20704A-26429 Vacuum Exhaust Monitor

20704A-26429 Vacuum Exhaust Monitor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:20704A-26429

- Get the latest price:Click to consult

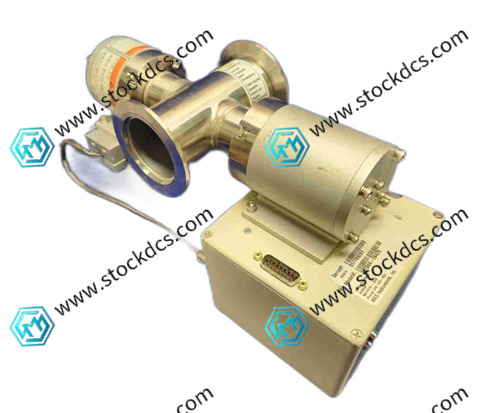

20704A-26429 Vacuum Exhaust Monitor

Product Details Introduction

20704A-26429 Vacuum Exhaust Monitor Product Overview and Application Fields

The 20704A-26429 vacuum exhaust monitor is the core monitoring equipment in the vacuum system exhaust process, with high-precision vacuum degree acquisition, real-time exhaust status monitoring, and abnormal alarm functions, supporting multi-channel parameter detection and data recording traceability. It adopts anti-interference sensing design and stable communication module, which can adapt to multi working condition exhaust monitoring requirements from low vacuum to ultra-high vacuum. It can provide real-time feedback of exhaust system operating parameters and link with the control system to achieve fault warning, providing guarantees for the stability and safety of vacuum technology. It is widely used in industrial manufacturing, scientific research experiments and other fields that have strict requirements for vacuum exhaust quality. The core applications are as follows:

1、 Semiconductor and Electronic Manufacturing Field

Core scenario: Adapt to the vacuum exhaust system in the semiconductor wafer manufacturing process, monitor the exhaust vacuum degree and gas flow parameters of process chambers such as etching and thin film deposition in real time, ensure stable exhaust process to avoid impurity residue affecting chip yield; Applied to the infrared detector Dewar vacuum exhaust station, it synchronously collects key data such as vacuum degree and temperature during the exhaust process, and uploads it to the data system through the communication module to achieve full process recording and traceability; Monitor the vacuum exhaust process supporting electronic component packaging, promptly detect exhaust abnormalities and trigger alarms to ensure packaging sealing.

2、 Photovoltaic energy field

Core scenario: Used in the exhaust system of PECVD equipment for solar cell manufacturing, accurately monitoring the changes in vacuum degree during the exhaust process of the coating chamber, ensuring sufficient discharge of reaction gases to improve the quality of thin film deposition; Adapt to the vacuum exhaust process of single crystal furnaces and polycrystalline silicon ingot furnaces, monitor the vacuum degree of exhaust in the furnace in real time, and avoid air mixing that affects crystal purity; Exhaust monitoring to support the lamination process of photovoltaic modules, ensuring complete removal of air and moisture from the chamber and preventing the formation of bubble defects inside the modules.

3、 Medical and scientific experimental fields

Core scenario: Vacuum beam channel exhaust monitoring adapted to particle therapy system, real-time feedback of vacuum degree status, timely detection of exhaust abnormalities to avoid system downtime, and ensuring the stability of particle beam transmission; The vacuum exhaust system applied to biosafety cabinets monitors the negative pressure exhaust status inside the cabinet, prevents harmful microorganisms or gas leakage, and ensures the safety of the experimental environment; As a supporting monitoring component for scientific research experimental equipment, it is used for monitoring the exhaust process of equipment such as vacuum ovens and electron beam evaporation devices, providing accurate parameter data to support experimental research.

4、 General industrial manufacturing field

Core scenario: Adapt to the exhaust system of vacuum reactors in the chemical industry, monitor the vacuum degree and corrosive gas discharge status during the exhaust process, and ensure reaction safety and environmental friendliness; Applied to the exhaust process of vacuum coating equipment (such as optical lenses and decorative coatings), the exhaust rate is adjusted in real time to maintain a stable vacuum environment and improve the uniformity of the coating layer; Support the exhaust monitoring of vacuum smelting equipment in the metallurgical industry to ensure the full discharge of impurity gases in the furnace and improve the purity of metal materials.

20704A-26429 Product imag

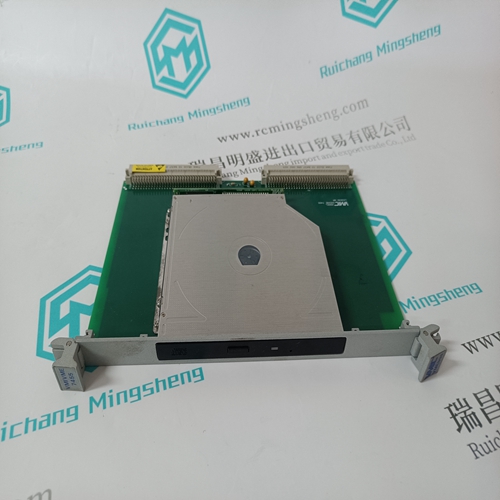

20704A-26429 ontroller Module

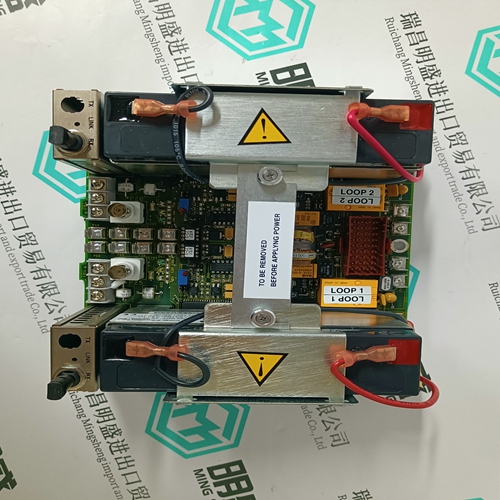

SR745-W2-P5-G5-HI-A Relay protector

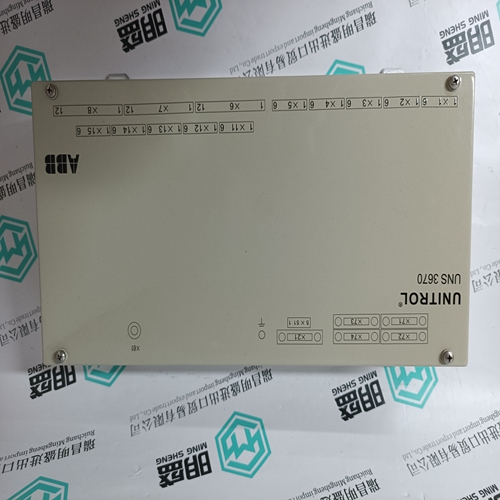

T1023-07C HIER466513P111 Logic input module

T1032-07C HIER466688P111 Logic input module

Other website links

EMERSO SE3008 KJ2005X1-SQ1模拟量输出卡

HE693ADC409A-22控制器模块

3HNM07686-1压力控制阀

| 710-806050-01 | 8020-SCP-424 | X-DO 24 01 |

| 710-805314-00 | 8020-SCP-423 | X-DO 32 51 |

| 710-805000-50 | 8020-SCP-401 | X-DO 32 01 |

| 710-800667 | 8020-SCP-333 | X-CI 24 51 |

| 710-774063-001 | 8020-SCP-332 | X-DI 32 04 |

| 710-679375-00 | 8020-SCP-323 | X-DI 32 03 |

| 710-678545-00 | 8020-SCP-322 | X-DI 32 02 |