Home > Product > Servo control system > Moog 77-159 valve

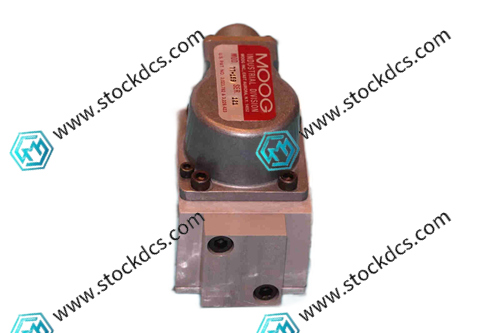

Moog 77-159 valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:77-159

- Get the latest price:Click to consult

MOOG 77-159 valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Integrated architecture of electro-hydraulic drive: The Moog 77-159 valve adopts an integrated design of "torque motor+hydraulic execution", consisting of a permanent magnet torque motor, a dual nozzle baffle pilot stage, and a slide valve execution stage. Compared with traditional mechanical valves, it eliminates the camshaft transmission structure and can directly control the valve opening through electrical signals, adapting to the flexible adjustment requirements of the engine's variable valve timing (VVT) system.

Engine operating condition adaptation design: The valve body adopts a compact and lightweight structure, with a weight controlled within the range of 200-300g, suitable for the narrow installation space of the engine cylinder head; The installation interface conforms to the standardized dimensions of the automotive industry and can be directly integrated into the valve mechanism of diesel or gasoline engines, reducing the cost of modification and adaptation.

Anti pollution sealing structure: The valve core and valve sleeve adopt a gap sealing fit, and the surface is treated with nitride hardening to improve wear resistance. Combined with replaceable imported dust-proof sealing rings, it can resist oil and dust erosion in the engine compartment and reduce valve core jamming faults caused by impurities.

2、 Core performance and control accuracy

Wide range pressure adaptation capability: The maximum working pressure can reach 21MPa, and it can adapt to the typical pressure range of the engine hydraulic system. It can maintain stable valve driving accuracy within the range of 5-18MPa, meeting the valve control requirements under different working conditions such as idle, acceleration, and high speed.

Millisecond level dynamic response: 100% step response time ≤ 8ms, frequency response above 50Hz, low friction design of torque motor significantly reduces signal lag, can quickly follow ECU instructions to adjust valve opening/closing timing, ensuring smooth power output of the engine under variable operating conditions.

High precision opening control: hysteresis error is less than 0.3%, valve opening resolution reaches 0.1mm, and closed-loop control is formed through mechanical feedback of valve core position to ensure precise matching of valve lift and timing at different speeds, helping the engine achieve a balance between low fuel consumption and high power.

MOOG 77-159 Product imag

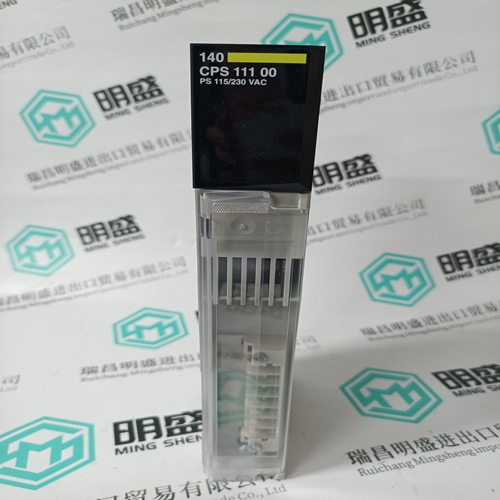

MOOG 77-159 Related website links

UFC921A101 3BHE024855R0101 Analog output card

UNS0119A-P,V101 3BHE029153R0101 Analog card

XDD501A101 3BHE036342R0101 Analog output card

Other website links

IC698CHS217 可编程逻辑控制器

TRICONEX 8310 电源模块

KOLLMORGEN S72402-NANANA伺服驱动器

| 345-L-P0-G0-H-E-M-N-N-SN-N-N | 531X300CCHAWM3 | IMCIS22 |

| 345-E-P5-G5-L-E-S-N-N-1E-D-H | 531X300CCHATM3 | IC3603A177AF6 |

| 345-E-P5-G5-H-E-S-N-N-SN-D-N | 531X300CCHASM3 | IC3603A177AF2 |

| 345-E-P5-G5-H-E-S-N-N-3E-D-N | 531X300CCHANM3 | IC3603A177AD2 |

| 345-E-P5-G5-H-E-S-N-N-1E-D-H | 531X300CCHAMM3 | IC3603A177AB2 |