Home > Product > DCS control system > Atlas Copco PF3007-G-DN-HW Controller

Atlas Copco PF3007-G-DN-HW Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PF3007-G-DN-HW

- Get the latest price:Click to consult

Atlas Copco PF3007-G-DN-HW Controller

Product Details Introduction

1、 Product Overview

Atlas Copco PF3007-G-DN-HW is a functional enhanced industrial tightening controller in the PF3000 series, equipped with DeviceNet (DN) communication interface, designed specifically for medium-sized assembly lines and automation workstations. This model is suitable for controlling the Tensor series power tools of Atlas Copco, achieving precise torque and angle control and data traceability. It is one of the key execution units in intelligent manufacturing environments.

2、 Technical parameters (brief)

Control methods: torque control, angle control, multi-stage compound tightening

Supporting communication protocols: DeviceNet (hardware integration) Ethernet、RS232、I/O

Compatible tools: Tensor ST, ES, ETX and other series of power tools

Tightening program capacity: can store multiple tightening programs, making it easy to switch between multiple types of operations

Human computer interaction: supports setting and monitoring through ToolsTalk PF software

Installation method: Standard industrial installation structure, suitable for control cabinet or workstation integration

3、 Application Fields

1. Assembly of automobiles and new energy vehicles

Suitable for assembly of key connections such as engines, transmissions, chassis systems, seat frames, etc

Support integration with vehicle assembly MES system or PLC system through DeviceNet protocol to achieve automated linkage between workstations

Precision tightening of bolts for new energy vehicle power batteries, electronic control boxes, and electric drive assemblies

2. Rail transit and heavy equipment

Medium to high torque tightening control for vehicle body, suspension, and braking components

Installation process of hydraulic cylinders, connecting plates, and motors for construction machinery

3. Industrial automation and robot assembly

Tightening tasks for industrial robot joints, electrical control cabinets, and body structures

Standard control platform for tightening units in automated production lines

4. Electronic and Electrical Manufacturing

Control of fixing bolts for plastic and metal parts on assembly lines of household appliances, power tools, etc

Tighten small torque screws on precision components such as electronic control modules and sensor housings

5. Integrated scenarios for intelligent manufacturing

Integrate with DeviceNet bus system to achieve multi controller and multi station linkage control

Real time data collection, feedback, quality traceability, supporting transparent assembly required by Industry 4.0

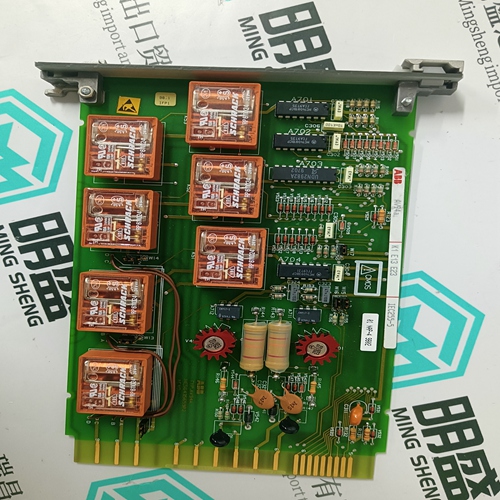

Product imag

Related website links

ASEA E-31709 Robot Circuit Board

IS200EPSMG1ABB Analog Input Module

AMAT 0190-24282 encoder module

Other website links

Kollmorgen CB06561 PRD-B040SSLZ-62 伺服控制器

| 339-E-P5-G5-L-E-S-N-N-SN-N-N | 3050-PIF-3 | IC3600VANA1D |

| 339-E-P5-G5-H-R-S-N-N-1E-D-N | 3050-EGW2 | IC3600VANA1 |

| 339-E-P5-G5-H-E-S-N-N-SN-D-N | 3050-EGW1 | IC3600TSUJ1B |

| 339-E-P5-G5-H-E-S-N-N-1E-D-H | 8010-SSK-374 | IC3600TSUJ1A |

| 339-E-P1-G1-H-E-S-N-P-3E-D-N | 8010-SPR-300 | IC3600TSUJ1 |

| 339-E-P1-G1-H-E-S-N-P-1E-D-N | 8010-SPR-250 | IC3600TSUD1B |

| 339-E-P1-G1-H-E-S-N-N-SN-D-N | 8010-SPR-200 | IC3600TSUD1 |

| 339-E-P1-G1-H-E-S-N-N-3E-D-N | 6DD1683-0CD5 | IC3600TSUC1A |