Home > Product > Servo control system > MOOG D633-322B servo valve

MOOG D633-322B servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:D633-322B

- Get the latest price:Click to consult

MOOG D633-322B servo valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Direct acting DDV drive architecture: MOOG D633-322B adopts a direct acting (DDV) design, with a permanent magnet linear force motor directly driving the valve core, eliminating the traditional servo valve nozzle baffle pilot stage, and achieving bidirectional displacement control without the need for an external pilot oil source. This structure reduces transmission links by more than 30%, making the valve body more compact and significantly reducing signal lag, making it suitable for closed-loop control systems with strict response speed requirements.

Integrated electronic control module: Built in valve core position control circuit board and pulse width modulation (PWM) drive circuit, integrating signal processing, power amplification, and valve core feedback functions. The circuit board adopts SMD chip technology and supports 24V DC wide voltage input (18-32V DC), which can directly receive external control instructions, simplifying system wiring and integration processes.

Anti pollution precision structure: The valve core and valve sleeve are made of AISI 440C martensitic stainless steel material. After precision grinding, the fit clearance is less than 1 μ m, and surface hardening treatment increases wear resistance by three times. Built in 10 μ m filter element, capable of withstanding NAS level 6 pollution hydraulic oil, and equipped with replaceable dust seals, significantly reducing the risk of failure in harsh environments.

2、 Core performance and control accuracy

High pressure and high flow output capability: The maximum working pressure can reach 35MPa, and the rated flow covers 3.8-100L/min under 7MPa valve pressure drop conditions. It can provide sufficient power for metallurgical equipment oil cylinders, hydraulic test bench actuators, etc. Even under low pressure differential conditions of 1-5 bar, stable flow output can still be maintained, suitable for multiple pressure level scenarios.

High frequency dynamic response: The frequency response is as wide as 40-60Hz (± 100% input signal), with a 100% step response time of ≤ 15ms, and can be as low as 5ms under some operating conditions. The low friction characteristics of linear force motors combined with closed-loop control can quickly follow command changes and effectively suppress dynamic hysteresis in hydraulic systems.

Micron level control accuracy: resolution ≤ 0.1%, hysteresis error below 0.2%, real-time feedback of valve core position is achieved through linear position sensor (LVDT), forming an electric closed-loop control. The minimum controllable flow rate is as low as 0.1L/min, which can meet the refined needs of semiconductor equipment such as micro feed and precision pressure regulation.

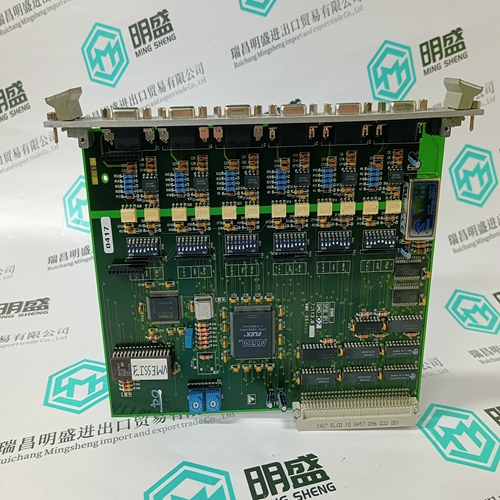

MOOG D633-322B Product imag

MOOG D633-322B Related website links

UNS0119A-P,V101 3BHE029153R0101 Analog card

XDD501A101 3BHE036342R0101 Analog output card

07KT98 GJR5253100R3160 Analog module

Other website links

TRICONEX 8310 电源模块

KOLLMORGEN S72402-NANANA伺服驱动器

TRICONEX RXM4201 模拟输入控制模块

| 345-E-P5-G5-H-E-M-N-N-3E-D-H | AMAT 0100-00409 | IC3603A143 |

| 345-E-P5-G5-H-E-M-N-N-2E-N-N | AMAT 0100-09117 | IC3600VRCC1A |

| 345-E-P1-G1-L-E-E-N-N-SN-D-N | AMAT 0100-03012 | IC3600VRCC1 |

| 345-E-P1-G1-H-E-S-N-N-SN-D-N | AMAT 0100-20026 | IC3600VRCA1 |

| 345-E-P1-G1-H-E-S-N-N-1E-N-N | AMAT 0100-77064 | 067-11732-0003 |