Home > Product > Servo control system > MOOG D633-313B servo valve

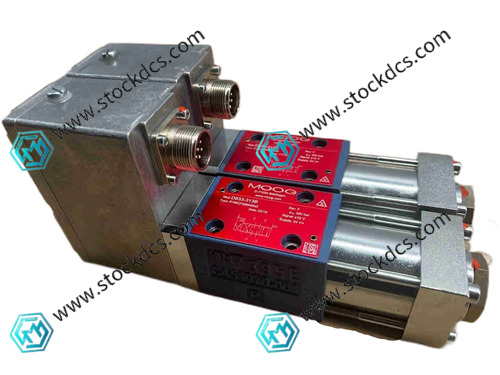

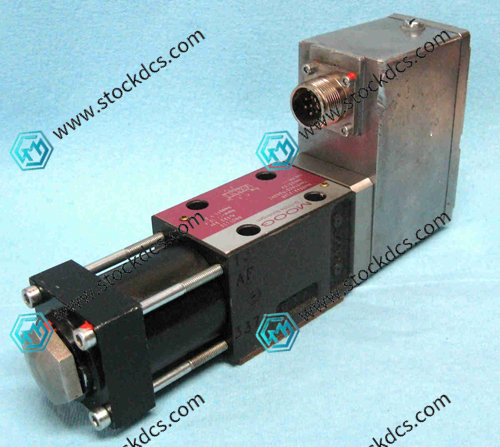

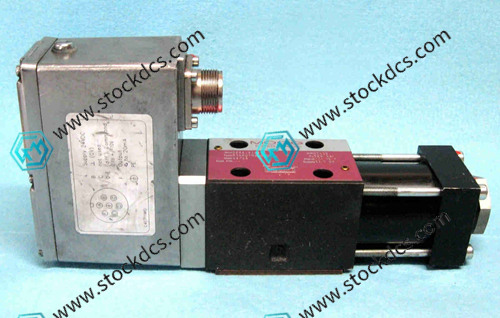

MOOG D633-313B servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:D633-313B

- Get the latest price:Click to consult

MOOG D633-313B servo valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Direct acting DDV core architecture: MOOG D633-313B continues the classic direct acting (DDV) design of the D633 series, with a permanent magnet linear force motor directly driving the valve core, eliminating the need for the nozzle baffle pilot stage of traditional servo valves, and achieving bidirectional displacement control without the need for an external pilot oil source. Compared to the multi-stage structure, which reduces the transmission links by about 30%, the valve body volume is more compact, and the signal transmission lag is significantly reduced, making it suitable for closed-loop control systems with strict response speed requirements, such as precision machine tool hydraulic servo mechanisms.

Integrated electronic control module design: Built in valve core position control circuit board and pulse width modulation (PWM) drive circuit, highly integrating signal processing, power amplification, and valve core feedback functions. The circuit board adopts industrial grade SMD surface mount technology and supports 18-32V DC wide voltage input. It can directly receive external control instructions without the need for additional driver modules, significantly simplifying the system wiring and integration process, and reducing the difficulty of equipment installation and debugging.

Anti pollution precision structure: The valve core and valve sleeve are made of AISI 440C martensitic stainless steel material, which has undergone ultra precision grinding treatment with a clearance of less than 1 μ m to ensure stable hydraulic oil flow field. The wear resistance of the surface is improved by more than 3 times through nitriding hardening process, and it is equipped with a 10 μ m filter element that can withstand NAS level 6 pollution hydraulic oil. It is matched with replaceable dust-proof sealing rings to effectively resist the invasion of dust and impurities, and reduce the risk of valve core jamming failure under harsh working conditions.

2、 Core performance and control accuracy

High pressure adaptation and flow characteristics: The maximum working pressure can reach 35MPa, and under the condition of 7MPa valve pressure drop, the rated flow covers 5-80L/min (subdivided according to specific parameters), which can provide stable power output for metallurgical equipment oil cylinders, hydraulic test bench actuators, etc. Even under low pressure drop conditions of 1-5 bar, the flow output stability can still be maintained, suitable for multi pressure level scenarios such as injection molding machine mold opening and closing control, and heavy-duty equipment hydraulic actuator drive.

High frequency dynamic response: The frequency response is as wide as 40-60Hz (± 100% input signal), with a 100% step response time of ≤ 15ms, and can be as low as 5ms under some working conditions. The linear force motor adopts a low friction design, coupled with real-time feedback of the valve core position, which can quickly follow the control instructions to adjust the flow rate, effectively suppress the dynamic lag of the hydraulic system, and ensure the control accuracy of high-speed moving equipment (such as automated production line robotic arms).

High precision control indicators: resolution ≤ 0.1%, hysteresis error below 0.2%, closed-loop control of valve core position achieved through linear position sensor (LVDT), ensuring accurate correspondence between input signal and flow output. The minimum controllable flow rate is as low as 0.1L/min, which can meet the refined needs of semiconductor equipment such as micro feed and precision pressure regulation, such as hydraulic servo positioning control for optical component processing equipment.

MOOG D633-313B Product imag

MOOG D633-313B Related website links

SCHNEIDER 140CPU31110 CPU module

ENK32 Analog features module

IOR810 P-HB-IOR-80010000 power contactor

Other website links

KOLLMORGEN S72402-NANANA伺服驱动器

TRICONEX RXM4201 模拟输入控制模块

TRICONEX 3624 三重冗余控制器

| 33VM82-020-19 | AMAT 0100-01884 | CE3100-423-0 |

| 33VM82-020-15 | 6SC9836-0FA03 | 04-1086-00 |

| 33VM62-220-8 | 55173-00 | 1GT101DC |

| 33VM62-220-6 | SBFP1-2222-48-23000 | IC3600VORA1A |

| 33VM62-220-3 | S20660-SRS | 073-650098-00 |

| 33VM62-220-19 | S60100-EI | 710-400180-000 |

| 33VM62-220-17 | SL3401-01000 | 073-500100-00 |