Home > Product > Servo control system > Moog G631 servo valve

Moog G631 servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:G631

- Get the latest price:Click to consult

MOOG G631 servo valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Two stage electro-hydraulic amplification architecture: Moog G631 adopts a two-stage design combining a pilot stage and an output stage. The pilot stage is driven by a dry torque motor to form a dual nozzle baffle valve, which enhances response sensitivity through a low friction structure; The output stage is a four-way slide valve, which uses a cantilever spring rod to achieve mechanical feedback of the valve core position. Compared with the direct acting design, it has more control stability in high flow scenarios.

Standardized integrated design: The installation bottom meets the ISO 4401 standard and can directly adapt to the standardized valve block interface of industrial equipment. Some models offer a fifth oil port option and support independent pilot oil source control, flexibly meeting the integration needs of different hydraulic systems and reducing modification costs.

Maintenance friendly structure: The pilot valve is equipped with a disc filter that can be replaced on site, and the filter element maintenance can be completed without disassembling the valve body, reducing the risk of failure caused by hydraulic oil pollution; The valve core and valve sleeve adopt precision matching technology, with strong component interchangeability, which shortens the downtime for maintenance.

2、 Core performance and control accuracy

Wide range pressure and flow adaptation: The maximum working pressure of the oil supply port can reach 31.5MPa (some models support 35MPa), and the rated flow rate covers 3.8-76L/min under a pressure drop of 7MPa. The maximum flow rate can reach 150L/min, which can match the multi power requirements from precision testing equipment to heavy-duty hydraulic actuators.

High dynamic response characteristics: The 100% step response time is only 10-15ms (under 210bar operating conditions), and the frequency response reaches 40-60Hz. The low friction design of the dry torque motor greatly reduces signal lag and can quickly adjust the flow rate according to instructions, adapting to high-speed motion control scenarios.

High precision control indicators: hysteresis error less than 0.5%, resolution better than 0.1%, mechanical feedback closed-loop ensures accurate correspondence between valve core displacement and input current, and micrometer level adjustment accuracy can be achieved in pressure and speed closed-loop control systems.

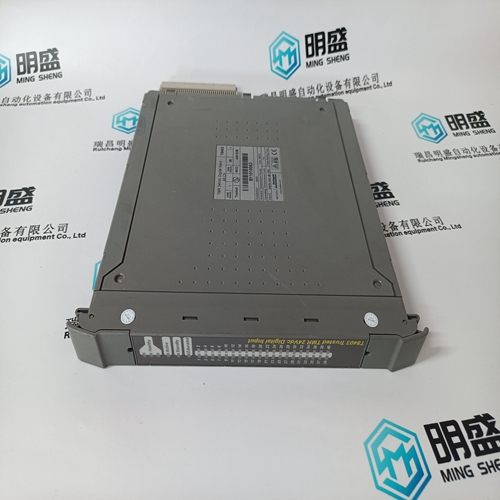

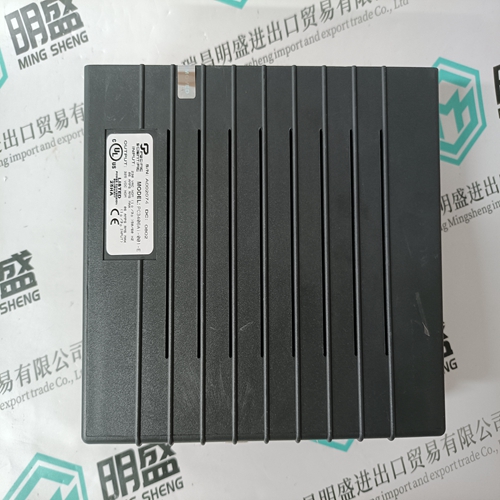

MOOG G631 Product imag

MOOG G631 Related website links

UFC911B108 3BHE037864R0108 Analog input module

UFC921A101 3BHE024855R0101 Analog output card

UNS0119A-P,V101 3BHE029153R0101 Analog card

Other website links

PQMII-T20-C电能质量检测仪

IC698CHS217 可编程逻辑控制器

TRICONEX 8310 电源模块

| 369-HI-B-M-0-0 | 531X305NTBAHG1 | IC3603A177CG6 |

| 369-HI-0-M-F-E-0 | 531X305NTBAEG1 | IC3603A177CG5 |

| 369-HI-0-M-0-0-E | SS2000-PCI | IC3603A177CF6 |

| 369-HI-0-M-0-0 | 531X301DCCAJM1 | IC3603A177AH9 |

| 369-HI-0-B-F-D-0-E | 531X301DCCAHM1 | IC3603A177AH2 |