Home > Product > Robot control system > AMAT Applied Materials 0010-68129 Valve Components

AMAT Applied Materials 0010-68129 Valve Components

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:0010-68129

- Get the latest price:Click to consult

AMAT Applied Materials 0010-68129 Valve Components

Product Details Introduction

1. Adaptation scenarios and functions (0010-68129)

Equipment adaptation: Matching AMAT semiconductor process equipment (such as CVD deposition and etching machines) for gas/liquid control in vacuum chambers, adapting to pipeline systems such as reaction gas transportation, cleaning solution circulation, and vacuum pumping.

Process compatibility: Focusing on high cleanliness and high vacuum scenarios, suitable for 1 × 10 ⁻³ -1 × 10 ⁻⁹ Pa vacuum range, compatible with corrosive/flammable and explosive gases such as silane, ammonia, fluoride, etc. in semiconductor manufacturing, avoiding process pollution.

Core function: Achieve precise on/off and flow regulation of pipeline media, cooperate with the equipment main control system to control the timing of media transportation, and ensure the process stability of thin film deposition, etching and other processes.

2. Accuracy and Performance (0010-68129)

Control accuracy: Valve opening adjustment accuracy ± 2%, switch response time ≤ 200ms, leakage rate ≤ 1 × 10 ⁻⁹ Pa · m ³/s (helium mass spectrometry detection), ensuring no medium leakage in high vacuum environment, suitable for 3x nanometer process requirements.

Structural performance: Adopting diaphragm type sealing structure (diaphragm material is perfluororubber FFKM), temperature resistance range -20-200 ℃, pressure resistance ≤ 1.0MPa, long-term use without aging deformation, service life exceeding 8000 switching cycles.

Drive mode: Supports pneumatic drive (working pressure 0.4-0.8MPa), can achieve opening ratio control through 4-20mA signal, suitable for remote control requirements of AMAT equipment PLC system.

3. Structure and Protection (0010-68129)

Protection design: The valve body is made of 316L stainless steel material (surface roughness Ra ≤ 0.8 μ m), and the inner wall is treated with electrolytic polishing, with no particle residue, meeting the semiconductor Class 1 cleanliness standard; Equipped with an external dust cover, suitable for clean workshop environment.

Installation and adaptation: Adopting sleeve/flange connection (interface specification 1/4 "-1/2"), supporting quick disassembly and assembly of pipelines, adapting to the compact space inside the equipment, with installation coaxiality error ≤ 0.1mm, avoiding sealing failure caused by pipeline stress.

Easy maintenance: Built in detachable filter element (pore size 5 μ m), can be cleaned and replaced separately; Equipped with position feedback sensors, the valve switch status is displayed through LED indicator lights, making it easy to quickly troubleshoot faults such as jamming and leakage.

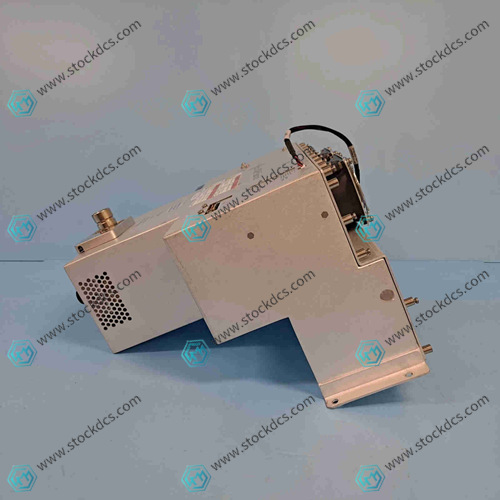

AMAT Applied Materials 0010-68129 Product imag

AMAT Applied Materials 0010-68129 Related website links

GE UR6UH Combustion engine relay module

UR8AH Relay module

UR8CH Relay module

Other website links

T3N225断路器

TRICONEX 8310 电源模块

1TGE120011R1111 控制器模块

| STF3720-3744-61-2 | SC402-001-T1 | SC753A-080-02 |

| STF3648-5268-61-56BC | SC403-027-T3 | SC905-034-01 |

| STF3640-4977-61-56BC | SC403-014 | SC933-001-NN-01 |

| STF3624-5604-61-56C | SC402-024-T2 | SC933-001-01 |

| STF3624-4976-61-56BC | SC403-013-T2 | SC753A-040-08 |

| STC3720-4085-56C | SC403-013-T4 | SC90200101NNN |