Home > Product > Gas turbine system > MOOG G631-3006B servo drive

MOOG G631-3006B servo drive

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:G631-3006B

- Get the latest price:Click to consult

MOOG G631-3006B servo drive

Product Details Introduction

1、 Infrastructure and driving characteristics

Two level mechanical feedback architecture: MOOG G631-3006B adopts a two-stage design of "torque motor+dual nozzle baffle pilot stage+main slide valve", and achieves mechanical feedback of valve core position through cantilever spring rod, which is significantly different from the direct acting DDV architecture of D633-317B. Although this design increases the transmission link, it has better control stability in high flow scenarios and is suitable for high-precision demand scenarios such as aerospace test benches.

Dry torque motor drive: Equipped with a dry dual air gap permanent magnet torque motor, it does not require oil immersion cooling. Compared with the D633-317B linear force motor, it reduces hysteresis errors caused by oil pollution and avoids internal wear of the motor, making it suitable for long-term continuous operation of industrial automation equipment.

Standardized compatible installation design: Adopting ISO 4401 standard installation bottom surface, supporting separate control of the fifth oil port, and adapting SAE standard thread for oil port connection. Although the interface type is less than D633-317B flange/thread optional configuration, it can directly replace traditional servo valves of the same specification, reducing the difficulty of hydraulic system transformation.

2、 Core performance and control accuracy

Wide range flow pressure adaptation: The maximum working pressure reaches 35MPa, and the rated flow covers 3.8-100L/min under a pressure drop of 35bar. The flow regulation range complements D633-317B (30-80L/min), which can meet the low flow requirements of small precision equipment and also adapt to the power supply of medium-sized actuators.

High frequency response dynamic characteristics: The frequency response reaches 40-60Hz, the maximum displacement of the valve core is 1.27mm, and torque balance is quickly established through a mechanical feedback rod. Although the 100% step response time is slightly longer than the 15ms of D633-317B, the response consistency is better under low pressure drop conditions, ensuring the flow stability of the blow molding equipment.

High precision control indicators: The dual nozzle baffle structure achieves low friction transmission, hysteresis error is ≤± 1%, and the resolution is slightly lower than the 0.1% of D633-317B. However, the anti-interference ability of mechanical feedback is stronger, and the control accuracy is more stable in metallurgical equipment with complex electromagnetic environment.

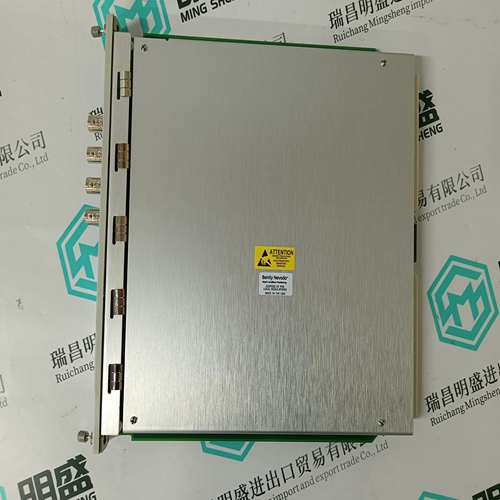

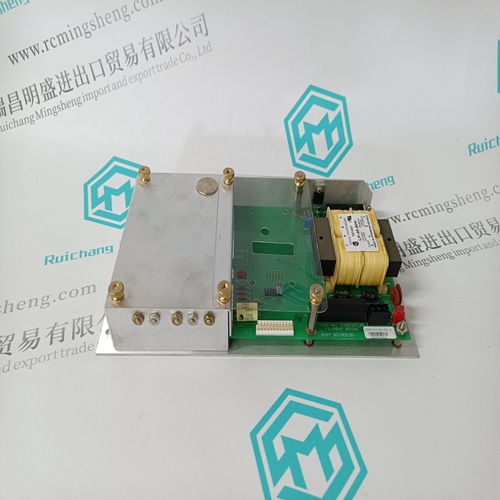

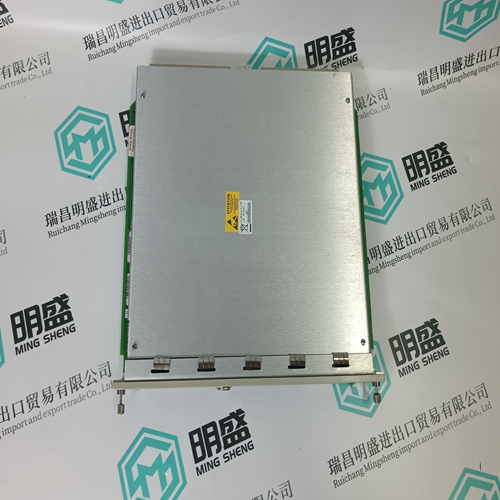

MOOG G631-3006B Product imag

MOOG G631-3006B Related website links

IS200DTAIH1ABB IS210DTAOH1AA Gas turbine module

IS200DTAIH1ACC IS210DTAOH1AA Gas turbine module

IS200DTAOH1ABA IS210DTAOH1AA Gas turbine module

Other website links

IC660ELB912G 网络接口板

DS200SIOCG1AEA 模拟量输出模块

DS200SHVMG1AGE传感器装置

| 33VM62-000-1 | IC3600VDAC1 | |

| 33VM52-020-9 | 3090-SCCT022 | IC3600VCDA1 |

| 33VM52-008-4 | 3090-RTM-317 | IC3600VBEA1 |

| 33VM52-000-4 | 3090-MCI101 | IC3600VBCU1B |