Home > Product > Gas turbine system > MOOG D633-317B power servo valve

MOOG D633-317B power servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:D633-317B

- Get the latest price:Click to consult

MOOG D633-317B power servo valve

Product Details Introduction

1、 Infrastructure and power adaptation characteristics

Direct acting DDV+power integration architecture: MOOG D633-317B continues the classic direct acting design of the D633 series, with a permanent magnet linear force motor directly driving the valve core. It also has an integrated power module that supports 18-32V DC wide voltage input. Compared to the single 24V power supply of D634-501A, the power supply is more flexible and can withstand ± 20% voltage fluctuations in industrial power grids, suitable for voltage instability scenarios such as metallurgy and petrochemicals.

High power linear force motor design: Adopting a super large driving force linear force motor, the output thrust is increased by more than 40% compared to D634-501A, which can drive larger diameter valve cores. With the stable power supply of the integrated power module, even under high pressure conditions of 35MPa, the smooth movement of the valve core can be maintained, avoiding control lag caused by insufficient power.

Multi oil compatible installation structure: Adopting ISO 4401 standard installation bottom, supporting three-way, four-way, and 2 * 2-way throttling control configurations, the oil port connection can be selected with SAE flange or UNF thread. Compared with the standardized interface of D634-501A, it is more suitable for the renovation needs of old hydraulic systems and can replace traditional servo valves without reworking the valve block.

2、 Core performance and control accuracy

High pressure and high flow output characteristics: The maximum working pressure reaches 35MPa (5000 psi), and the rated flow covers 30-80L/min under 7MPa valve pressure drop conditions. The upper limit of flow is 33% higher than D634-501A, which can provide sufficient power for medium-sized hydraulic actuators (such as casting equipment oil cylinders and pipeline valve drive devices) and is suitable for high load industrial scenarios.

High frequency dynamic response capability: The frequency response reaches 40-60Hz (± 100% input signal), and the 100% step response time is ≤ 15ms. Although slightly inferior to the 12ms of D634-501A, it has significant advantages in dynamic performance in high flow output scenarios, and can quickly follow pressure regulation instructions to ensure the pressure stability of the oil pipeline transportation system.

High precision closed-loop control indicators: achieved through LVDT valve core position sensor for electric closed-loop control, hysteresis error<0.2%, resolution<0.1%, comparable to D634-501A accuracy, but with better linearity under high pressure difference (25-35MPa) conditions, error ≤ ± 1%, which can meet the precision flow control requirements of casting equipment.

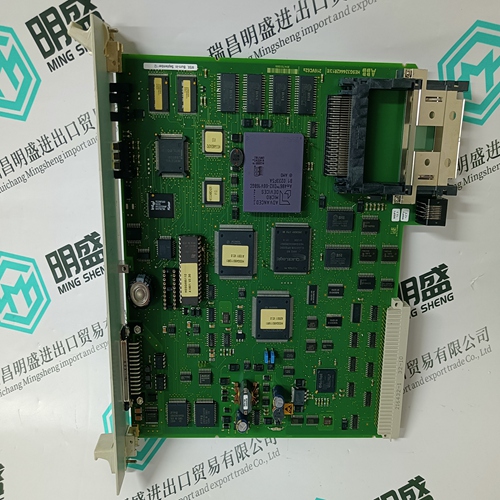

MOOG D633-317B Product imag

MOOG D633-317B Related website links

IS200DTAIH1ABB IS210DTAOH1AA Gas turbine module

IS200DTAIH1ACC IS210DTAOH1AA Gas turbine module

IS200DTAOH1ABA IS210DTAOH1AA Gas turbine module

Other website links

IC660ELB912G 网络接口板

DS200SIOCG1AEA 模拟量输出模块

DS200SHVMG1AGE传感器装置

| 33VM62-000-1 | IC3600VDAC1 | |

| 33VM52-020-9 | 3090-SCCT022 | IC3600VCDA1 |

| 33VM52-008-4 | 3090-RTM-317 | IC3600VBEA1 |

| 33VM52-000-4 | 3090-MCI101 | IC3600VBCU1B |