Home > Product > Robot control system > MOOG G631-3004B servo valve

MOOG G631-3004B servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:G631-3004B

- Get the latest price:Click to consult

MOOG G631-3004B servo valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Direct acting servo control architecture: MOOG G631-3004B adopts a direct acting (DDV) design, which directly drives the valve core movement through a permanent magnet linear force motor, eliminating the traditional pilot stage structure, reducing hydraulic oil flow resistance and response lag, and improving control sensitivity while making the structure more compact. It is suitable for industrial scenarios with strict requirements for space and dynamic performance.

Integrated electric feedback design: Equipped with a high-precision valve core position sensor and closed-loop control circuit, it can collect real-time valve core displacement signals and feedback them to the control module, forming accurate position closed-loop control. Combined with the stable driving force of the linear force motor, it effectively reduces the impact of external interference on control accuracy and ensures the consistency of output flow.

Anti pollution hydraulic design: The valve core and valve sleeve adopt a gap sealing structure, and the surface is specially hardened (such as nitriding or chrome plating process) to improve wear resistance and corrosion resistance. It can withstand a certain degree of impurity pollution in hydraulic oil, reduce valve core sticking faults caused by insufficient oil cleanliness, and adapt to scenarios with long maintenance cycles in hydraulic systems.

2、 Core performance and control accuracy

Wide range pressure adaptation capability: The maximum working pressure can reach 31.5MPa, which can adapt to the requirements of medium and high pressure hydraulic systems. It can maintain stable flow output within the pressure range of 5-31.5MPa, which can meet the low-pressure control needs of small precision equipment and also adapt to the medium and high pressure power supply scenarios of medium-sized industrial machinery.

Efficient dynamic response characteristics: The frequency response can reach 80-120Hz (± 100% input signal), and the step response time is ≤ 12ms. It can quickly follow the dynamic changes of the input signal to adjust the flow output, effectively suppressing the dynamic lag of the hydraulic system and ensuring the control stability of high-speed motion actuators (such as precision machine tool spindles and test bench actuators).

Ultra high control accuracy indicators: hysteresis error ≤ 0.2%, resolution below 0.1%, flow repeatability accuracy better than 0.3%. Fine flow adjustment can be achieved within the full flow range (usually covering 2-50L/min, depending on the operating conditions), and even in low flow fine-tuning scenarios (such as pressure closed-loop control), high output stability can be maintained.

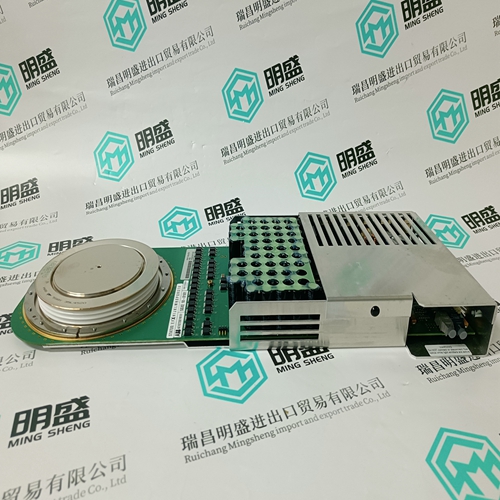

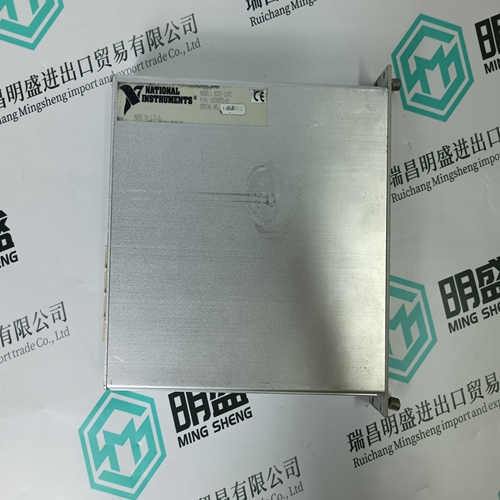

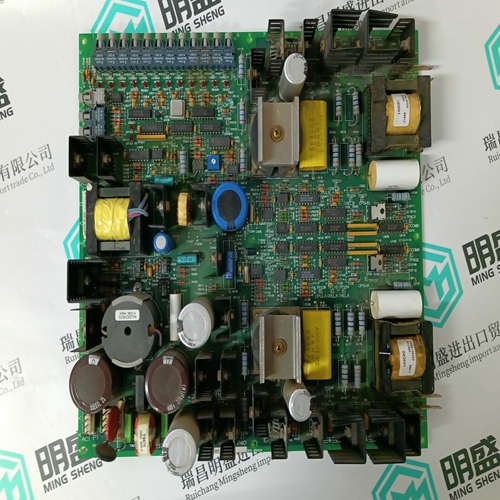

MOOG G631-3004B Product imag

MOOG G631-3004B Related website links

UDD406A 3BHE041465P201 Analog card

ABB UFC911B106 3BHE037864R0106 Analog module

UFC911B108 3BHE037864R0108 Analog input module

Other website links

3BHB015651P0001 中央处理器模块

SUE3000 1VCR007346控制面板模块

PQMII-T20-C电能质量检测仪

| 369-Hi-R-M-0-0-H-0 | 531X306LCCBDM2 | IC3603A279A |

| 369-HI-R-M-0-0-0-E | 531X306LCCBBM1 | IC3603A278F |

| 369-HI-R-M-0-0-0 | 531X306LCCBAM1 | IC3603A278B |

| 369-HI-R-M-0-0 | 531X306LCCAEM1 | IC3603A277A |

| 369-HI-R-B-0-E-0-E | 531X306LCCADM1 | IC3603A200C |

| 369-HI-R-B-0-0 | 531X306LCCAAM1 | IC3603A200B |