Home > Product > Robot control system > Moog D682Z4743F servo valve

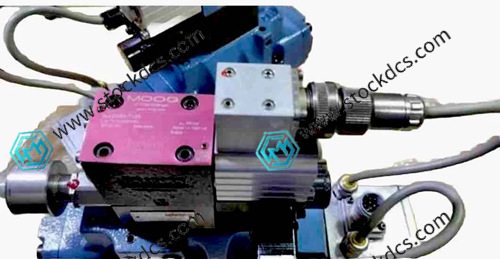

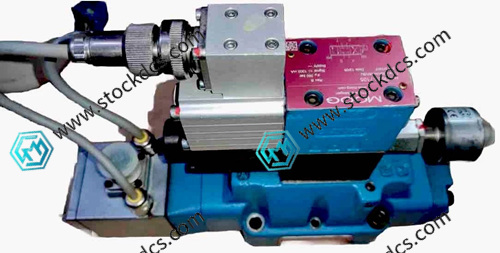

Moog D682Z4743F servo valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:D682Z4743F

- Get the latest price:Click to consult

MOOG D682Z4743F servo valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Pilot controlled architecture design: Moog D682Z4743F adopts a two-stage control architecture consisting of a pilot stage and a main stage combination. The pilot stage drives a small flow valve core through a high-precision electromagnetic motor, thereby controlling the action of the main stage large flow valve core. Compared with the direct acting design, it can achieve larger flow output and meet the requirements of high-pressure and large flow hydraulic systems.

Modular valve core components: The valve core and valve sleeve are designed with modular precision fit, with strong interchangeability of components, and the surface is treated with a special wear-resistant coating to reduce the impact of hydraulic oil pollution on valve core wear. At the same time, it is easy to quickly replace core components during later maintenance, reducing downtime for repairs.

High protection whole machine packaging: The valve body shell and electrical interface are designed according to IP65 protection standards, which can effectively resist dust intrusion and short-term spraying in industrial environments. The control circuit part is additionally sealed with moisture-proof treatment, suitable for harsh working conditions such as metallurgy and mining with high humidity and dust.

2、 Core performance and control accuracy

High pressure and high flow output capability: The maximum working pressure can reach 35MPa, and under the condition of 7MPa valve pressure drop, the rated flow can cover up to 150-300L/min (depending on the specific model subdivision parameters), which can provide sufficient power for large hydraulic actuators (such as forging machine oil cylinders and ship servos) and meet the flow requirements of high-power equipment.

Excellent dynamic response characteristics: The frequency response can reach 50-80Hz (± 100% input signal), and the step response time is ≤ 20ms. It can quickly capture changes in the input signal and adjust the flow output, effectively suppressing the hysteresis phenomenon of the hydraulic system and ensuring the control stability of high-speed motion equipment.

High precision flow control indicators: hysteresis error ≤ 0.3%, resolution below 0.15%, fine adjustment of flow can be achieved within the full flow range, even in low flow fine-tuning scenarios (such as precision pressure control), output stability can be maintained, suitable for industrial equipment with strict control accuracy requirements.

MOOG D682Z4743F Product imag

MOOG D682Z4743F Related website links

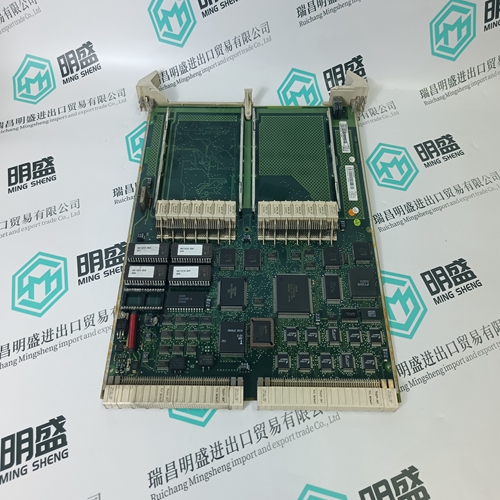

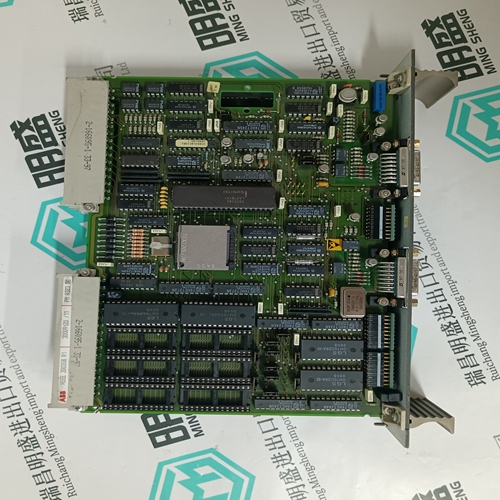

UCD208A101 3BHE020018R0101 Analog module

UDD406A 3BHE041465P201 Analog card

ABB UFC911B106 3BHE037864R0106 Analog module

Other website links

1TGB302004R5003 继电保护装置

BENTLY 149992-01 通道继电器卡

Metso D201291安装控制器

| 3BSE003911R0001 | 531X301DCCCAM1 | IC3603A291A |

| 369-LO-R-M-0-D-0-E | 531X301DCCBAG1 | IC3603A290A |

| 369-LO-0-M-F-E-0 | 531X301DCCAXM1 | IC3603A285A |

| 369-HI-R-M-F-P-H-E | 531X301DCCAWM1 | IC3603A282A |

| 369-HI-R-M-F-0-H-E | 531X301DCCATM1 | IC3603A281A |

| 369-HI-R-M-0-0-H-E | 531X301DCCASM1 | IC3603A280A |