Home > Product > Robot control system > MOOG D633Z317A Hydraulic Servo Valve

MOOG D633Z317A Hydraulic Servo Valve

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:D633Z317A

- Get the latest price:Click to consult

MOOG D633Z317A Hydraulic Servo Valve

Product Details Introduction

1、 Infrastructure and Design Characteristics

Direct acting servo valve architecture: MOOG D633Z317A adopts a direct acting (DDV) design, relying on a permanent magnet linear force motor to directly drive the valve core in both directions. Compared with traditional servo valves, it eliminates the need for a pilot stage structure, has a faster response speed and a more compact structure, and is suitable for industrial scenarios with high requirements for space and dynamic performance.

Integrated electric feedback system: Built in valve core position electric feedback loop and pulse width modulation (PWM) drive circuit. The valve core displacement signal can be transmitted back to the control module in real time, forming a closed-loop control. Combined with the high driving force characteristics of the linear force motor, it achieves ultra-high control accuracy.

High protection integrated design: The control circuit board is encapsulated in the valve body according to the IP65 protection level, which can resist dust and water vapor erosion in industrial environments, simplify external wiring, reduce the risk of circuit failure caused by environmental factors, and adapt to harsh working conditions such as metallurgy and ships.

2、 Core performance and control accuracy

Excellent dynamic response capability: Continuing the characteristics of the D633 series, the frequency response can reach 60-90Hz (± 100% input signal), with a step response time of only 15ms. It can quickly adjust the flow output according to changes in the input signal, meeting the dynamic control requirements of high-speed hydraulic actuators.

Ultra high control accuracy index: resolution less than 0.1%, hysteresis less than 0.2%, can achieve fine adjustment of flow rate, even in low flow range, can maintain stable output, suitable for injection molding machines, precision machine tools and other equipment with strict requirements for displacement or pressure control accuracy.

Wide range pressure and flow adaptation: The maximum working pressure can reach 35.0MPa, and the flow range covers 3.8-100L/min under 7.0MPa valve pressure drop conditions. It can flexibly match hydraulic systems of different power levels, meeting the needs of small testing equipment and large industrial machinery.

3、 Safety and operational characteristics

Power off automatic centering function: Built in centering spring structure, when the system voltage is cut off, the valve core can automatically reset to the neutral position, cutting off the hydraulic oil passage, avoiding equipment damage or safety accidents caused by the actuator losing control, and improving the emergency safety of the system.

Simple system integration interface: The valve body circuit design simplifies the connection process with industrial computers, without the need for additional complex drive modules. It can be directly connected to PLC or dedicated controllers, reducing the difficulty and cost of system integration and shortening the equipment debugging cycle.

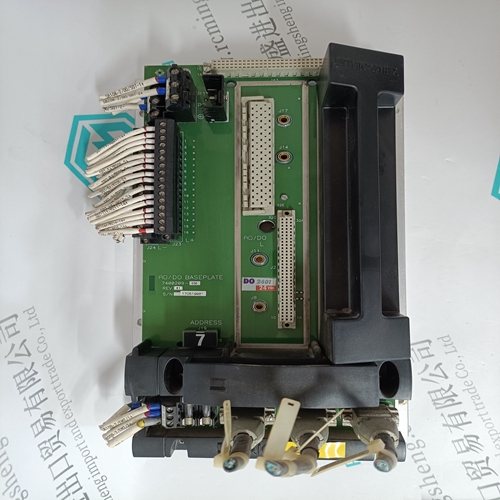

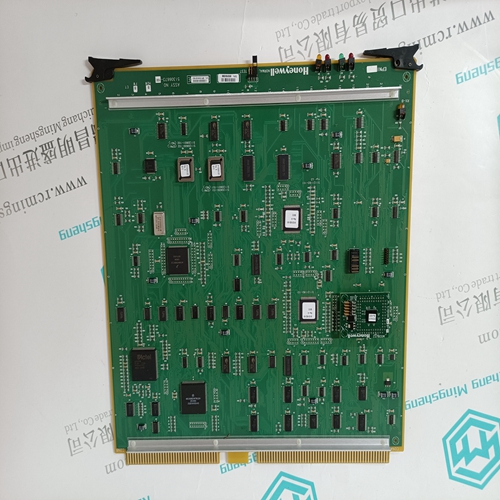

MOOG D633Z317A Product imag

MOOG D633Z317A Related website links

UAD154A 3BHE026866R0101 Control card

UCD208A101 3BHE020018R0101 Analog module

UDD406A 3BHE041465P201 Analog card

Other website links

HIMA F3226A 数字输出模块

Woodward 8290-185 控制器

Motorola MVME2400-0361 单板计算机

| 3N63-000-2 | 531X302DCIAMG1 | 04116J79G0002 |

| -3KB11 | 531X302DCIAHG2 | IC3606SIIA9A |

| 3HNM07686-1 | 531X302DCIABG4 | IC3606DEXB1A |

| 3HAB2207-1 | 531X302DCIABG3 | IC3603A328A |

| 3BSE003911R0001 PFRA101 | 531X302DCIAAG5 | IC3603A300A |