Home > Product > DCS control system > AMAT Applied Materials 0010-26057 Wafer Lift Assembly

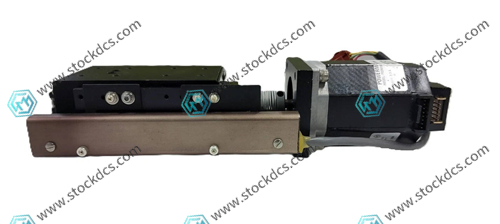

AMAT Applied Materials 0010-26057 Wafer Lift Assembly

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:0010-26057

- Get the latest price:Click to consult

AMAT Applied Materials 0010-26057 Wafer Lift Assembly

Product Details Introduction

1. Adaptation scenarios and functional positioning (0010-26057)

Equipment adaptation: Designed specifically for AMAT semiconductor core process equipment, it accurately matches CVD (chemical vapor deposition), PVD (physical vapor deposition), and dry etching machines, especially suitable for the vacuum chamber structure of high-end equipment such as Producer and Endura. It can be directly connected to the original automation control system of the equipment without the need for additional interface protocol modification.

Wafer compatibility: It focuses on mainstream wafer sizes of 300mm and supports compatible processing of 200mm wafers through replaceable wafer carrier trays (made of high-purity alumina ceramic). The tray surface is polished (roughness Ra ≤ 0.2 μ m) to avoid scratching the thin film on the wafer surface.

Core function: Responsible for the lifting, transportation, and precise positioning of wafers between the "transfer chamber process chamber detection chamber", cooperating with equipment robotic arms to complete wafer handover. Before key processes such as film deposition and etching, ensure that the coaxiality error between the wafer and the chamber electrodes and spray heads is ≤ 0.1mm, ensuring process uniformity.

2. Precision control and performance parameters (0010-26057)

Positioning accuracy: Adopting sub micron level closed-loop control technology, real-time feedback of lifting position is provided through the built-in grating ruler (resolution 0.1 μ m), coupled with precise driving of servo motor (rated torque 0.8N · m), the lifting positioning error can be controlled within ± 0.5 μ m, meeting the strict requirements of 3x nanometer and higher advanced processes for wafer position.

Stability of operation: The drive system is equipped with a harmonic reducer (transmission accuracy ≤ 1 arc minute) to eliminate lifting and shaking caused by mechanical clearances; The lifting speed supports stepless adjustment of 0.5-5mm/s, and automatically switches to low-speed mode (0.5mm/s) when the wafer approaches the bottom of the chamber or the robotic arm to avoid wafer displacement caused by impact.

Environmental adaptability: The core components (motors, sensors) adopt vacuum compatible design (leakage rate ≤ 1 × 10 ⁻⁹ Pa · m ³/s), which can operate stably in high vacuum environments ranging from 1 × 10 ⁻³ to 1 × 10 ⁻⁷ Pa; The components that come into contact with the wafer are made of plasma corrosion-resistant materials (such as Y ₂ O3 coated ceramics), which are suitable for the fluorine and chlorine plasma environment in the etching process, and have a service life of over 10000 hours.

AMAT Applied Materials 0010-26057 Product imag

AMAT Applied Materials 0010-26057 Related website links

Alcatel Lucent SNPQARBAAF interface module

Alcatel Lucent 3EH72050JBAA port digital interface card

ALCATEL-LUCENT IPU3AC9EAA Communication Module

Other website links

Motorola MVME167-33B工业控制系统

TRICONEX 3704E模拟输入模块

REXROTH VT-VPCD-1-16/V0/1-P-1 R901089559放大器模块

| T2HNRHK-LNN-NS-00 | CACR-IR1020C | 067-02121-0005 |

| T23NRLH-LNF-NS-00 | CACR-SR30BZ1SD | 46413701 |

| T23NRHK-LNF-NS-00 | CACR-UP130AABY18, | 3HAB-8572-106 |

| T23NRHJ-LNN-NS-00 | CACR-PR01AE4ESY6 | 061-01666 |

| T23NRHJ-LNF-NS-00 | CACR-IR30SEB | 23158-100 |

| T22NSLS-LDN-SS-02 | CACR-SR15BY1SSY48E | 067-11384-0000 |