Home > Product > PLC programmable module > AMAT Applied Materials 0090-77082 Chemical Technology Equipment

AMAT Applied Materials 0090-77082 Chemical Technology Equipment

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

AMAT Applied Materials 0090-77082 Chemical Technology Equipment

Product Details Introduction

1. Process adaptation and core functions (0090-77082 chemical technology equipment)

Process positioning: As an AMAT chemical technology equipment, it is likely to focus on the chemical processing of semiconductor wafers, referring to the characteristics of CMP (chemical mechanical planarization) or ECD (electrochemical deposition) processes, and may be used for core processes such as wafer surface polishing, metal deposition, or chemical cleaning

Compatible with wafer specifications: It is expected to support processing of 150mm, 200mm, and 300mm multi size wafers, and can quickly switch between different sizes of wafers through modular configuration, adapting to the needs of research and development and mass production in multiple scenarios

Chemical compatibility: Compatible with various wafer materials such as copper, tungsten, oxide, and polycrystalline silicon, and can adapt to strong acid/alkali grinding solutions, electroplating solutions, and other chemical reagents. Refer to Mirra CMP system's ability to handle multiple materials

2. Performance and Control Accuracy (0090-77082 Chemical Technology Equipment)

Process uniformity: By using multi zone control modules (such as multi zone grinding heads in CMP systems), high-precision uniform processing from the center to the edge of the wafer can be achieved. The deviation of film thickness or polishing removal rate is controlled at the nanometer level, meeting the requirements of 3x nanometer and more advanced nodes

Real time monitoring capability: may integrate in-situ endpoint detection technology (such as broadband spectroscopy, eddy current sensing), track process progress in real time, avoid wafer scrap caused by over or under processing, similar to Reflexion LK CMP's Window in Pad technology

Automation control: supports full process programmable control, can preset multiple process formulas, adapt to the chemical treatment needs of different metals or dielectrics such as copper, nickel, tin, etc., and reduce downtime adjustment time with the "no teaching" automation function

3. Structural design and protective performance (0090-77082 chemical technology equipment)

Anti corrosion structure: The chambers and pipelines that come into contact with chemical reagents are made of corrosion-resistant materials (such as PTFE, Hastelloy alloy), with reference to the CMP system's adaptation design for strong acid/alkali reagents, to avoid equipment loss caused by chemical corrosion

Wafer protection: may be equipped with SafeSeal similar to Nokota ECD system ™ Components: Seal and protect the wafer before processing, cooperate with the cleaning and inspection process after processing, reduce the risk of chemical contamination, and decrease the wafer scrap rate

Maintenance convenience: adopting modular process chamber design, supporting HotSwap ™ The outdoor operation mechanism of the chamber can replace consumables or maintain components without interrupting production, improving equipment operating efficiency

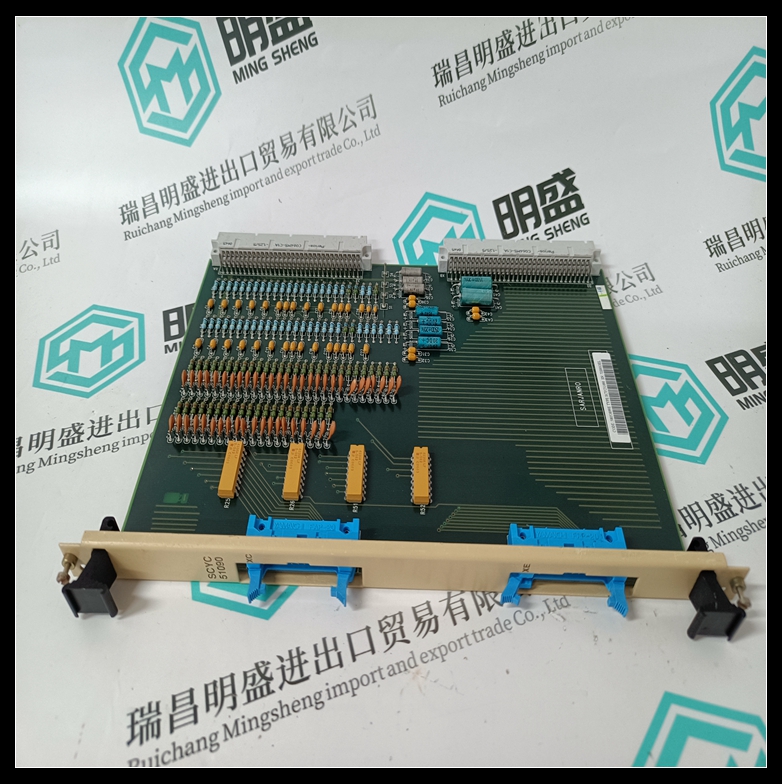

AMAT Applied Materials 0090-77082 Product imag

AMAT Applied Materials 0090-77082 Related website links

Alcatel Lucent 90-4459-44 CPU board

Alcatel Lucent 644-0091-001 Interface Board

Alcatel Lucent SNPQARBAAF interface module

Other website links

HIMA F3226A输入模块

HONEYWELL SC-UCMX01 51307195-175 混合I/O模块

Motorola MVME167-33B工业控制系统

| UR6EV | CACR-R44SFB | 97-9045-01 |

| UR6DH | CACR-CSL20DL16AAA | 60-0208-03 |

| UR6CH | CACR-SRA5AB | 859-8379-001B |

| UR6AV | CACR-UP60AAB | PRE-913425 |

| UR1800 | CACR-SR10B21SSY367 | EXP-MX |

| UNS0881a-P,V1 3BHB006338R0001 | CACR-SR05BC1ES-Y278 | 97-9525-20 |