Home > Product > DCS control system > AMAT Applied Materials 0100-09008 Pneumatic Control Board

AMAT Applied Materials 0100-09008 Pneumatic Control Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:0100-09008

- Get the latest price:Click to consult

AMAT Applied Materials 0100-09008 Pneumatic Control Board

Product Details Introduction

1、 Core Control Performance Characteristics

Multi channel precise pneumatic control

Specially designed for pneumatic systems, it can simultaneously control multiple valves (presumably supporting 8-16 independent channels), and accurately adjust the pressure, flow rate, and flow direction of compressed air through digital signals. Using pulse width modulation (PWM) technology and closed-loop feedback control, the valve response time is ≤ 10ms, and the pressure regulation accuracy reaches ± 0.01MPa, which can meet the micro level action control requirements of components such as wafer transfer robotic arms and vacuum chucks.

Efficient signal processing and collaborative capabilities

Equipped with an industrial grade microcontroller (presumably ARM Cortex-M series), it has high-speed instruction execution capability, can analyze control signals from the device main control unit in real time, and synchronously output valve drive instructions. Support seamless linkage with the 0190-24007 single board computer to achieve the coordinated operation of pneumatic actuators and electrical control systems, ensuring the continuity of processes such as wafer handling and process chamber switching.

Adaptive load regulation function

Built in load detection algorithm that can automatically adjust output parameters based on the operating status of pneumatic actuators such as cylinders and grippers. When there is a sudden change in load (such as when a robotic arm grabs a wafer), it can instantly compensate for air pressure and flow rate, avoid motion lag or positioning deviation, and adapt to the dynamic operation requirements of semiconductor equipment under multiple working conditions.

2、 Security protection and monitoring characteristics

Full link fault protection mechanism

Integrated multiple safety protection functions, including overvoltage protection (automatic cut-off of gas source for pneumatic system pressure ≥ 1.2MPa), overcurrent protection (triggering power outage when driving circuit current exceeds the limit), disconnection detection (instant alarm for valve control line disconnection), and timeout protection (error message within 10 seconds of incomplete action). The fault response time is less than 5ms, which can quickly cut off the dangerous path and lock the output to prevent mechanical collision or wafer damage.

Real time status monitoring and communication

Equipped with RS485/Modbus communication interface, it supports real-time uploading of 12 key parameters such as valve switch status, pipeline pressure, and board temperature to MES system. By integrating LED indicator lights and fault code output functions, operation and maintenance personnel can quickly locate problems (such as valve sticking or abnormal pressure) through the equipment panel or backend system, shortening the troubleshooting time.

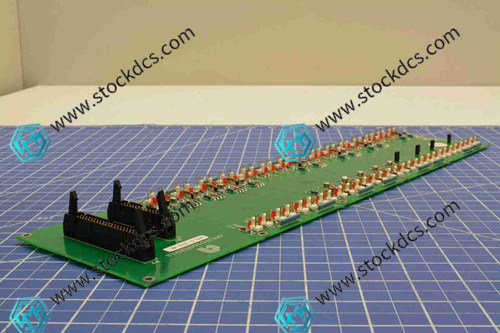

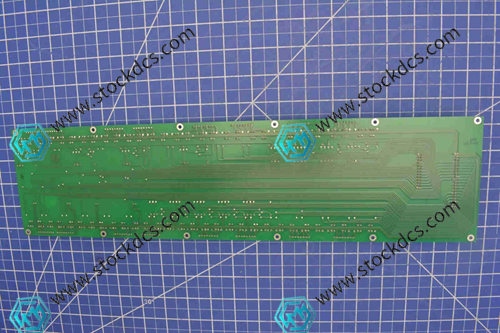

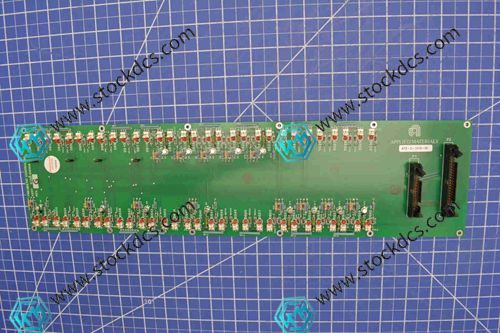

AMAT Applied Materials 0100-09008 Product imag

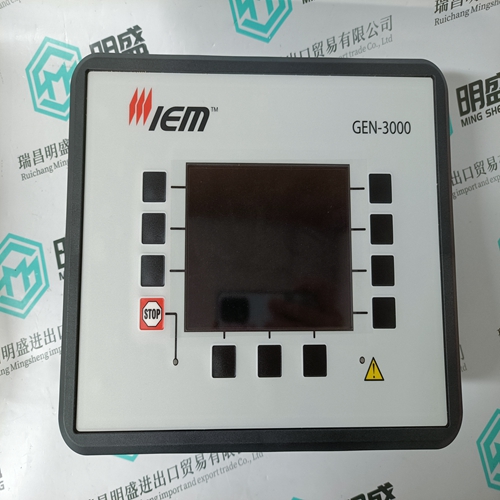

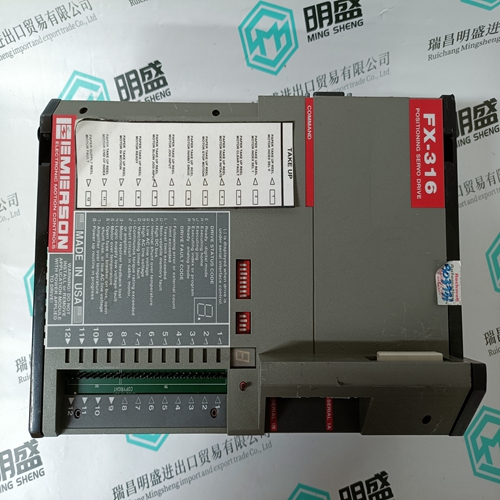

AMAT Applied Materials 0100-09008 Related website links

AI810 Analog Input Module

DILA-22 relay

DILER-40-G XTRM1 0A40 Miniature Control Relay

Other website links

IC3600LSFD1B控制板

IC3600EPSS1B 电源供应板

IC3600SSKAIE驱动器板

| PXI-6143 | Gespac GESSIO-1E | 3300/05-22-00-00 |

| PXI-6031E | GESBUS-4M | AO820 3BSE008546R1 |

| PXI-6030E | Gespac GESSBS-6A | PM856AK01 3BSE066490R1 |

| PXI-5690 | SC520M 3BSE016237R1 | ECZ FPR3700001R0001 |

| PXI-5651 | GESPAC GESMDC-1 GESMDC-1 9728 MDC-1 | 3300/50-01-01-00-00 |

| PXI-5441 | ULSTEIN TENFJORD 5880-PC1017 | 3HNP04378-1 |