Home > Product > DCS control system > AMAT Applied Materials 0010-76136 Heater

AMAT Applied Materials 0010-76136 Heater

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

AMAT Applied Materials 0010-76136 Heater

Product Details Introduction

Product Overview

AMAT 0010-76136 heater is the core heating element in Applied Materials semiconductor equipment, used to provide stable and controllable heat in process chambers or related components. It ensures the thermal environment required for deposition, etching, diffusion and other processes through precise temperature control. This component is usually used as a spare part for equipment maintenance and replacement to ensure the continuity and consistency of the process.

Technical parameters (inferential information, specific values may vary depending on the model)

Function type: Special heater for semiconductor process equipment

Installation location: Process chamber, chamber flange, gas channel or wafer tray area

Power supply method: commonly used for AC heating (110V/220V AC), depending on the equipment configuration

Power range: typically between several hundred watts to several kilowatts, to meet different heating requirements for various processes

Temperature control: supports precision control and can be closed-loop controlled with thermocouples or infrared sensors

Material characteristics: Made of high-temperature alloy or ceramic based materials, with corrosion resistance and high temperature resistance properties

Working environment: high vacuum, clean room process conditions

Application scenarios

Chemical Vapor Deposition (CVD)/Physical Vapor Deposition (PVD)

Heat the process chamber or substrate to ensure the deposition rate and uniformity of the thin film.

etching process

Control the temperature of the cavity wall, reduce the deposition of by-products, and improve etching consistency.

ion implantation

Moderate heating is applied to the carrier or cavity to ensure process stability and doping effect.

Gas flow path/chamber heating

Prevent gas condensation in pipelines or chambers to improve gas transport efficiency and purity.

Wafer heat treatment

Provide thermal cycling for some processes to improve wafer surface structure or stress relief.

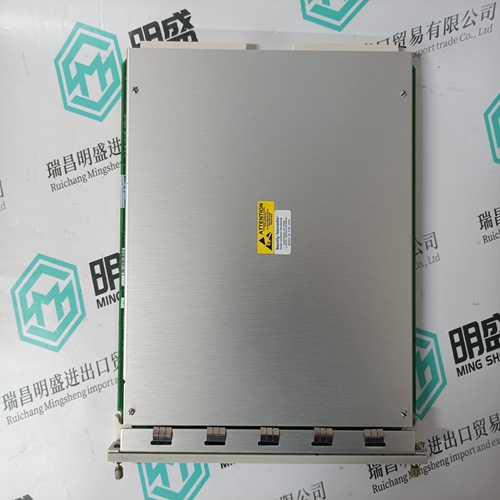

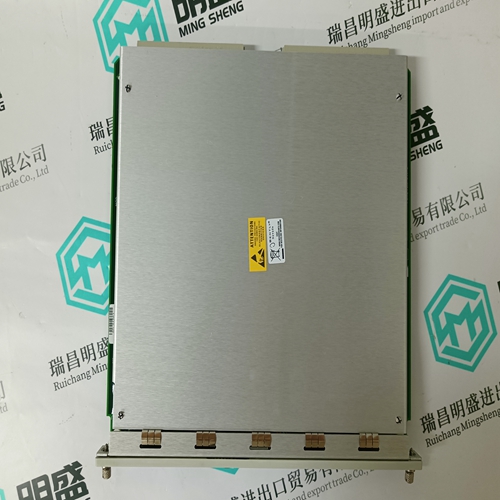

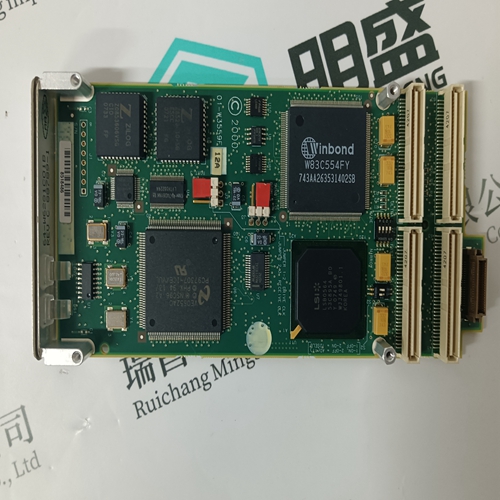

AMAT Applied Materials 0010-76136 Heater Product imag

AMAT Applied Materials 0010-76136 Heater Related website links

BENTLY 146031-01 Communication module

SCYC55830 58063282A processor card

SR750-P1-G1-S1-HI-A20-G Relay protector

Other website links

REXROTH PPC-R22.1N-T-NN-P1-NN-FW 伺服控制器

REXROTH HNC100 SYHNC100-BLA-23/W-08-C-0-E23-A014 独立控制器

B&R 5AC600.GPI0-K05 印刷电路板

| AMAT 0190-76276 | AMAT 0190-36253 | AMAT 0190-13213 |

| AMAT 0190-12032 | AMAT 0190-36320 | AMAT 0190-13214 |

| AMAT 0190-10243 | AMAT 0190-36331 | AMAT 0190-13220 |

| AMAT 0190-33704 | AMAT 0190-36349 | AMAT 0190-13221 |

| AMAT 0190-14415 | AMAT 0190-36351 | AMAT 0190-13235 |

| AMAT 0190-43080 | AMAT 0190-36351-A | AMAT 0190-13274 |

| AMAT 0190-01403 | AMAT 0190-36471 | AMAT 0190-13295 |

| AMAT 0190-17884 | AMAT 0190-36497 | AMAT 0190-13313 |

| AMAT 0190-83792 | AMAT 0190-36532 | AMAT 0190-13415 |