Home > Product > DCS control system > AEG MODICON PC-K084-785 Controller Module

AEG MODICON PC-K084-785 Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PC-K084-785

- Get the latest price:Click to consult

AEG MODICON PC-K084-785 Controller Module

Product Details Introduction

Packaging machinery linkage control: relying on 14 in 10 out I/O interfaces to interface with bag making, sealing, and labeling equipment, collecting material conveying speed through 100K high-speed counting, outputting pulse commands to achieve process synchronization, and CANopen main station linkage servo system to improve packaging accuracy

Automated material transfer line: Integrating belt conveyor and drum line sensor signals through two serial interfaces (RJ45), using high-speed counting to monitor the conveyed load, outputting relay/transistor commands to control start stop and speed regulation, ensuring continuous material transfer

Non standard automation equipment integration: As the control core, it adapts to various sensors and actuators, supports customized logic programming with a program capacity of 400-900Kb, and IP20 protection meets the installation needs of industrial sites, reducing OEM equipment development costs

Food and beverage filling production line: Collecting liquid level and flow sensor signals, adjusting the opening of the filling valve through high-speed pulse output, and linking the CANopen main station with temperature control equipment to achieve precise control of filling volume and real-time optimization of process parameters

Small automated three-dimensional warehouse: docking stacker position encoder and cargo position detection sensor, using dual phase high-speed counting to achieve precise positioning, outputting motor start stop instructions, uploading inventory data to the management system through serial interface

Electronic component sorting equipment: collects the conveying speed and quantity of components through 8-channel single-phase high-speed counting, outputs sorting mechanism action instructions, and the CANopen main station links with the visual inspection module to achieve rapid removal of non-conforming products

HVAC system control: collects temperature, humidity, and air quality sensor data, controls the operation of fans and regulating valves, supports communication with building automation systems through two serial interfaces, and adapts to the working temperature of -10 ° C~+55 ° C in the computer room environment

Control of small-scale chemical reaction kettle: Receive temperature and pressure sensor signals, output control instructions for heating, cooling devices, and feeding pumps, adjust valve opening through high-speed pulse to ensure stable and controllable reaction process

Lithium battery electrode cutting equipment: using 100K high-speed pulse output to control the cutting blade movement frequency, monitoring the electrode conveying tension through high-speed counting, CANopen main station linkage servo drive, improving cutting size accuracy

Logistics sorting line control: docking with barcode scanners and weight sensors, outputting sorting mechanism action instructions through I/O interfaces, high-speed counting and sorting efficiency statistics, serial interfaces for data exchange with logistics management systems

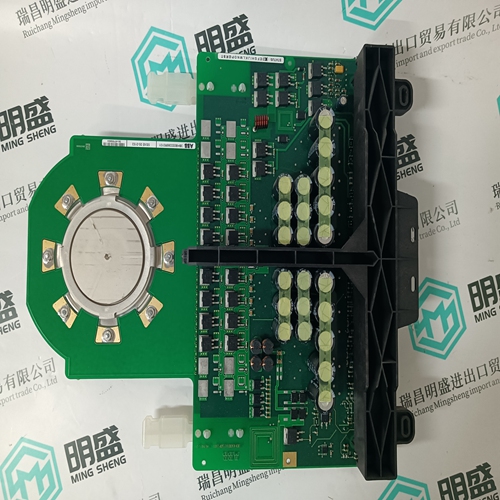

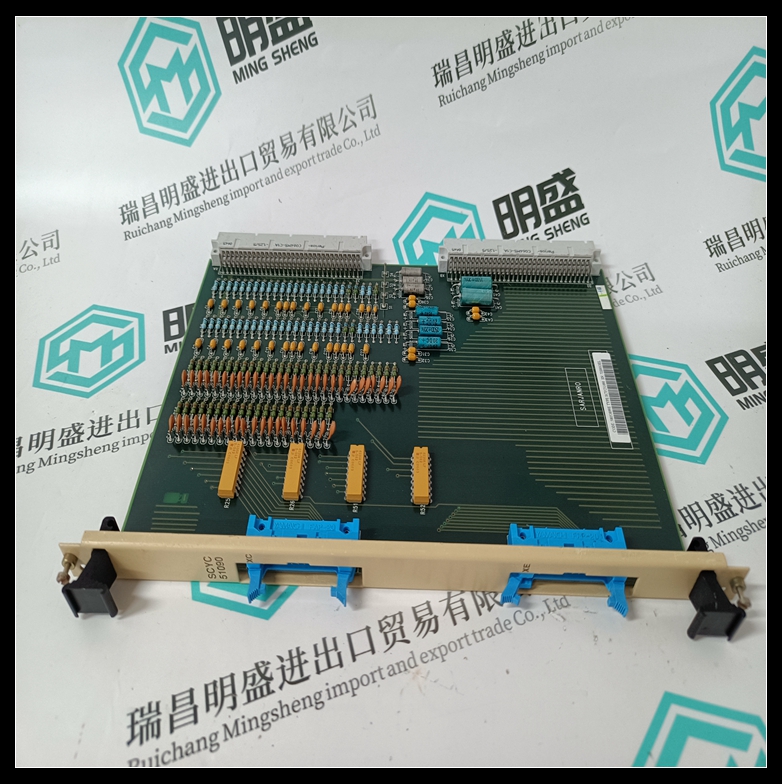

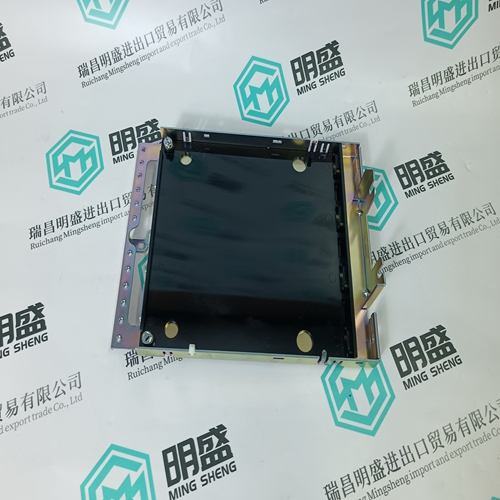

AEG MODICON PC-K084-785 Product imag

AEG MODICON PC-K084-785 Controller Module

AO2020 CALDOS25 gas analyzer

Siemens 6ES7488-3AA00-0AB0 Analog Input Module

CI631 3BSE016347R1 interface module

Other website links

WOODWARD 8237-1247速度控制器

A-B 1394C-SJT22-A数字伺服控制器

DIZ232.1 (029.232376)计数器模块

| 710-606238-005 | 193X803BCG03 | 073-614993-000 |

| 710-606238-00 | 6DD1684-0FB0 | 500-22333-001 |

| 710-566009-00 | 6DD1684-0EF0 | 710-660800-00 |

| 710-566008-00 | 03-417236-00 | 720-06888-001 |

| 710-566006-00 | A90-031-03 | 710-658177-20 |

| 710-5000817-00 | 531X111PSHABG1 | F31X128HMSA |