Home > Product > Servo control system > MAGNETEK CIMR-G5M41P5 Vector Crane Controller

MAGNETEK CIMR-G5M41P5 Vector Crane Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

MAGNETEK CIMR-G5M41P5 Vector Crane Controller

Product Details Introduction

MAGNETEK CIMR-G5M41P5 Vector Crane Controller

product overview

CIMR-G5M41P5 is a vector control variable frequency drive/controller customized for lifting equipment in the Magnetek G5 series, with high reliability, high response, and motion control performance optimized for lifting conditions.

Core product features

Vector control optimized specifically for lifting conditions

Adopting closed-loop/open-loop magnetic flux vector control technology to achieve high-precision lifting and walking control;

Maintain strong torque at low speeds to prevent slipping or drifting during heavy loads.

Four quadrant operation support

Support lifting/lowering and forward/reverse braking control, compatible with regenerative braking module, to achieve energy feedback or efficient braking.

Anti sway function

An optional anti sway control logic module can be used for applications such as bridge cranes and grab buckets, effectively reducing load sway and improving lifting efficiency and safety.

Quick response braking logic

Built in brake control curve setting, supporting rapid shutdown and coordinated braking control in case of power failure, enhancing personnel and equipment safety.

Multiple security protection mechanisms

Including brake confirmation logic, encoder fault detection, motor stall detection, brake failure alarm, etc., it meets the industrial safety requirements under EN and ANSI standards.

Self learning motor parameter tuning

Before starting, automatic recognition of motor parameters can be performed to improve the accuracy and efficiency of drive control, especially suitable for replacing original equipment motors or retrofitting situations.

Special functional parameter group for lifting equipment

The setting interface is specifically designed for three typical driving modes: lifting, lateral movement, and longitudinal movement, with clear parameter classification and easy debugging.

Typical application areas

Main lifting and auxiliary walking mechanism of bridge crane

Control system for gantry crane lifting equipment

Variable frequency drive device for electric hoist

Grab bucket lifting equipment (with brake coordinated control)

Speed regulation and anti-skid control of metallurgical lifting equipment

Motion coordination and load management of heavy-duty loading and unloading equipment

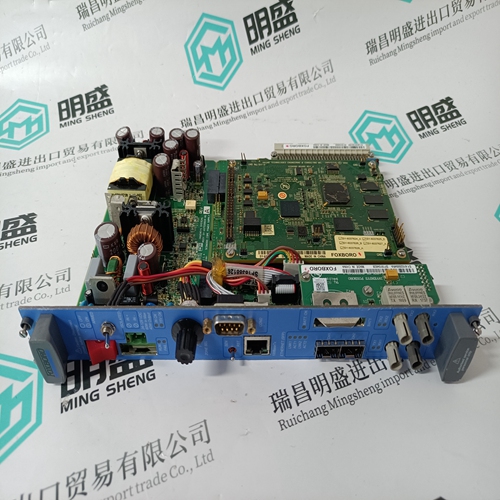

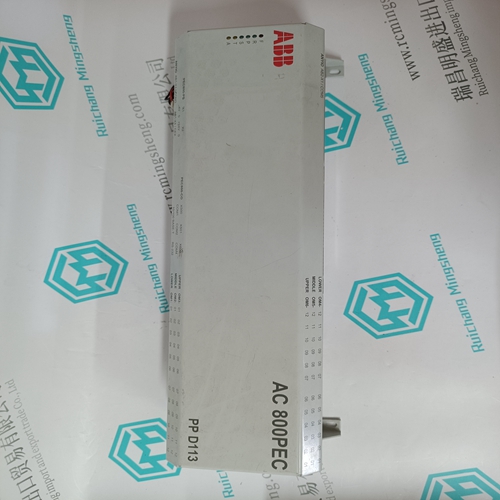

Product imag

Related website links

Asea EB0524B01 driver input power board

Other website links

| 760-P5-G5-S5-LO-A20-R | 8030-CC-15 | 531X308PCSAEG1 |

| 760-P5-G5-S5-HI-A20-R-T | 8030-CC-10 | F31X133PRUABG1 |

| 760-P5-G5-S5-HI-A10-R | 8030-CBP-320 | F31X134EPRBHG1 |

| 760-P5-G5-D5-HI-A1-R | 8030-ADP-100 | F31X166MHCACG1 |

| 760-P1-G1-S1-LO-A20-R | 8020-SCP-722 | 830-23461-000 |

| 760-P1-G1-S1-LO-A10-R | 8020-SCP-721 | F31X135PRGBBG1 |

| 750-P5-G5-S5-LO-A20-R-E | 8020-SCP-644 | 8030-HOM-211 |