Home > Product > Servo control system > GIDINGS&LEWIS 502-03638-60 Programmable Industrial Computer

GIDINGS&LEWIS 502-03638-60 Programmable Industrial Computer

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:502-03638-60

- Get the latest price:Click to consult

GIDINGS&LEWIS 502-03638-60 Programmable Industrial Computer

Product Details Introduction

Product Overview

GIDINGS&LEWIS 502-03638-60 Programmable Industrial Computer is a core computing platform designed for industrial automation systems, specifically for CNC machine tools and automated production lines. This computer can centrally control and program manage multi axis motion, I/O modules, and peripheral actuators, support complex process logic processing, and can achieve data communication with the upper computer or factory information system. Its robust industrial design ensures stable operation in harsh environments.

Technical parameters (typical features)

Processing capability: Built in high-speed industrial processor, supporting multitasking real-time computation.

Storage configuration: Equipped with non-volatile storage for program storage and process data recording.

I/O Expansion: Can connect multiple digital/analog I/O modules and support expansion control requirements.

Communication interface: Supports industrial Ethernet, serial port, and fieldbus interfaces, making it easy to integrate with PLC, servo drive, and HMI systems.

Program compatibility: Supports ladder diagrams, functional blocks, and text programming, making it convenient for users to customize control logic.

Industrial adaptability: resistant to vibration, high temperature, electromagnetic interference, and meets industrial environmental standards.

Security protection: It has overcurrent, overvoltage, and power-off protection functions to ensure the safety and reliability of the system.

Application scenarios

CNC machine tool

Centralize control of spindle, tool magazine, feed system, and cooling system to achieve high-precision machining.

Automatic production line

Control material conveying, assembly, inspection, and sorting units to achieve production line automation.

robot system

Manage robot joint movements and end effector operations to achieve multi task collaboration.

Packaging and Printing Machinery

Centralize the management of actions such as feeding, cutting, positioning, and packaging.

Factory informatization docking

Can be connected to MES/ERP systems to achieve production data collection and remote monitoring.

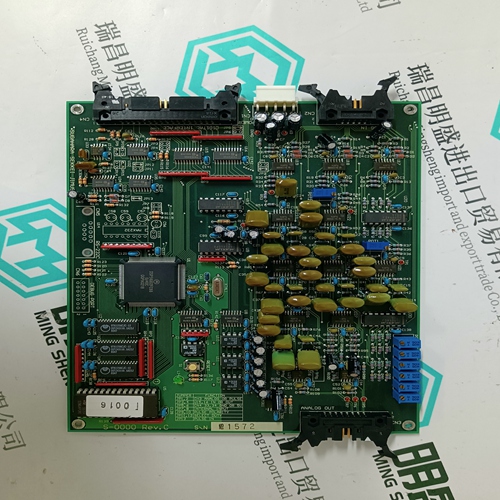

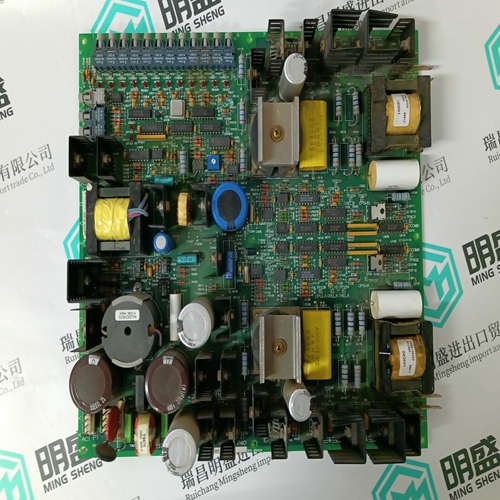

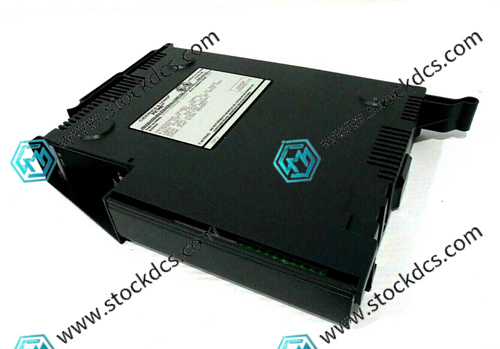

Product imag

Related website links

AMAT 0190-11415 Digital Input Module

ASEA 2668 184-447 Communication Module

Other website links

ABB 3BHE046836R0101 GFD563A101控制器模块

| S21HNNA-HGNL-00 | SC724A-001 | SCE955NN-501-01 |

| S21GNNA-RNNC-00 | SC453-038-15 | SC904-021-01 |

| RSER200-4 | SC723B001-01 | SCE903A3-002-01 |

| RMV-142D | SC726A-001-PM72013 | SCE903AN-002-01 |

| RMV-132D | SC723A-001-PM72008 | SN31HCYR-LNK-NS-01 |

| RMV-122D | SC102-001 | S34GNNA-HGNE-00 |