Home > Product > PLC programmable module > TOYOTA TD-1879-4 Communication Module

TOYOTA TD-1879-4 Communication Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

TOYOTA TD-1879-4 Communication Module

Product Details Introduction

product overview

The TOYOTA TD-1879-4 communication module is an industrial communication interface unit used in Toyota's automated production system, mainly responsible for data exchange and signal transmission between the main control system and various peripheral devices. This module supports high-speed and stable data communication, enabling real-time collaboration between multiple devices. It is an important component of production line control, robot system integration, and detection data transmission.

Technical parameters (example, specific subject to actual model information)

Communication mode: Supports RS-232/RS-485/CAN/Industrial Ethernet or Toyota specific bus protocol

Data transmission rate: up to several Mbps (depending on the selected protocol)

Signal isolation: optocoupler isolation/transformer isolation to enhance anti-interference capability

Interface form: Industrial terminal block/RJ45/D-sub interface (according to design)

Working voltage: DC 5V/12V/24V (depending on model)

Working environment: -10 ℃ to+55 ℃, earthquake resistant, dust-proof, and electromagnetic interference resistant

Installation method: rack mounted/modular plug-in

Application scenarios

Automated production line data exchange

Real time data transmission and synchronous control between production workstations

Realize precise communication linkage in multi machine collaborative processes

Industrial Robot System

Transmitting motion control commands between robots and control cabinets

Feedback the robot status to the main control system

Detection and monitoring system

Transfer the quality data collected by the detection equipment to the central controller

Support online quality traceability and statistical analysis

Remote monitoring and maintenance of equipment

Support communication with upper computer, SCADA system or remote server

Realize remote diagnosis of equipment status and parameter updates

Logistics and Transportation System

Control the data exchange between conveyor lines, sorting equipment, etc. and the main control system

Ensure that material flow is synchronized with production pace

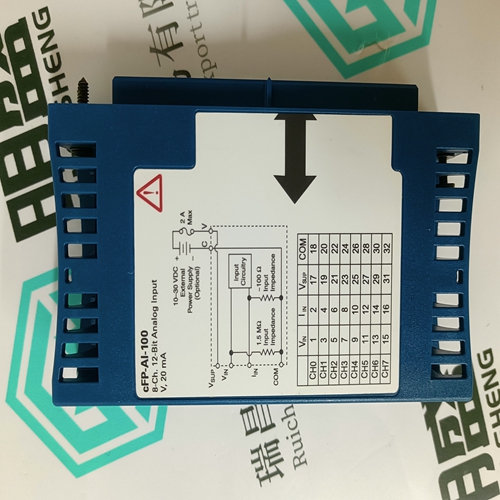

Product imag

Related website links

ASEA 2668 0002-AE Connection Unit Circui

ABB P8840 8-channel temperature module

Other website links

| 269PLUS-DO-120N-120 | S60300-550 | IC3600TCSA1 |

| 269PLUS-DO-100P-125VDC | SMARTSTEP-240 | 073-805000-00 |

| 269PLUS-DO-100P-120 | SS420-10001 | 073-651089-00 |

| 269PLUS-DO-100N-120 | SS400-10082 | 6ES5470-7LC12 |

| 269PLUS-120N-HI | PSX100 | 281-500305-3 |

| 269PLUS-120N-125VDC | P18003330RR | 531X309SPCAJG1 |

| 269PLUS-120N-120 | 51250-60 | F31X111PSHAFG1 |