Home > Product > Gas turbine system > Atlas Copco PF4000-G-DN-HW Power Focus Controller

Atlas Copco PF4000-G-DN-HW Power Focus Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

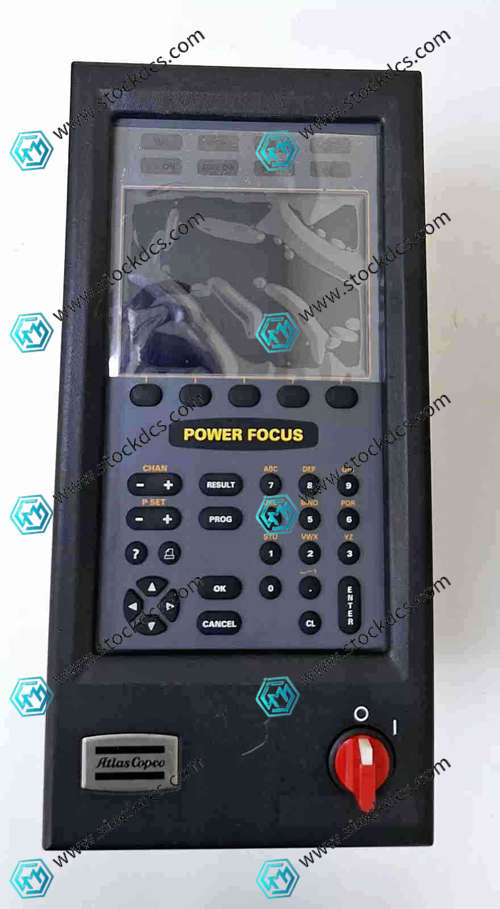

Atlas Copco PF4000-G-DN-HW Power Focus Controller

Product Details Introduction

product name

Atlas Copco PF4000-G-DN-HW Power Focus Controller

Product Introduction

This controller is a member of the Atlas Copco Power Focus 4000 series, designed specifically for driving and controlling Tensor series power tools, with high-precision, multi-stage torque control capabilities.

The meaning of the model is as follows:

PF4000: Power Focus 4000 Series Platform

G: Graphic interface version with local display and user interface

DN: Supports DeviceNet industrial communication protocol

HW: Standard hardware configuration

Main application areas

Assembly of automobiles and their components

Suitable for high-precision tightening processes, such as bolt connections for engines, transmissions, chassis, seat structures, door hinges, etc

Can be integrated with the MES system of the production line to achieve torque data traceability and quality control

New energy vehicles and power battery manufacturing

Tightening of screws for housing assembly of battery modules, electrical control boxes, and electric drive systems

Support torque+angle composite strategy to improve connection reliability and prevent missed/over twisting

Automated tightening workstation and robot assembly line

Integrated with industrial robots for automated tightening applications

Supports DeviceNet communication and can collaborate with the main control system to perform tightening tasks

Rail transit, aviation, and engineering machinery manufacturing

Applied to assembly processes with high safety requirements, such as suspension structures, steering components, cabin connections, etc

Meet the requirements of torque control consistency, process monitoring, and bolt identification

Manufacturing of household appliances and electrical equipment

Suitable for mixed line tightening operations with small batches and multiple product types

Support fast program switching and workstation switching logic

Summary of controller advantages

Support high-precision tightening control (± 3% repeatability)

Multi stage tightening strategy, angle monitoring, anti twist detection function

The graphical local interface facilitates debugging and on-site setup

Can integrate multiple industrial communication protocols (such as DeviceNet)

Support for use with Tensor STR, EBL, STB and other series of tools

Can upload data to MES/SCADA to achieve quality traceability and production line collaboration

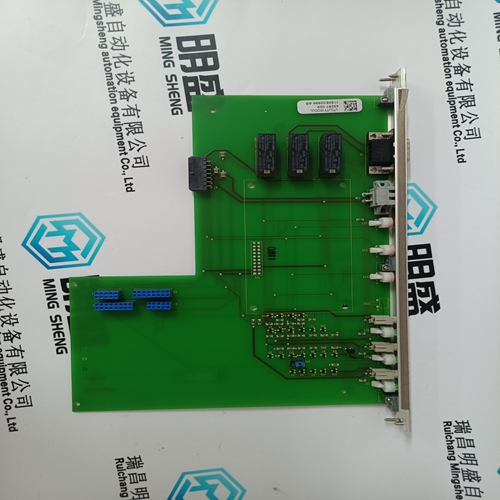

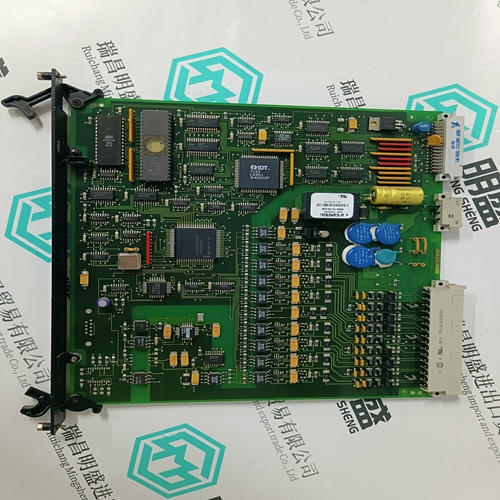

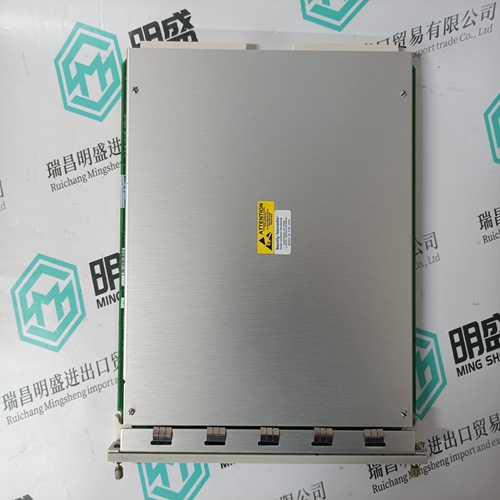

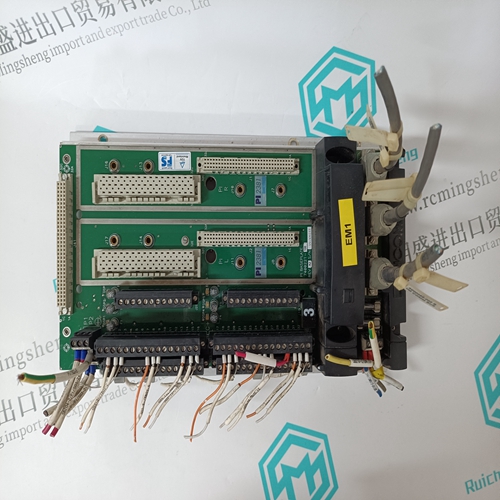

Product imag

Related website links

Teknic SST-1500-XCX Digital Servo Drive

ABB SB822 3BSE018172R1 rechargeable

Other website links

| 208-600673-3 | 531X111PSHALG1 | F31X121PCRALG1 |

| 208-500686-1 | 193X740AFG01 | 201-500117-1 |

| 201-500283-2 | PA215T-133 | 710-658051-20 |

| 1BF41-0BC0 | PA210T-135 | F31X111PSHATG1 |

| 196918A-02 | PA210T-133 | 0284699-000 |

| 1747-L552 1747-L553 1747-L551 | PA208T-135 | 531X310SNDABG1 |