Home > Product > Servo control system > TEL Tokyo Electron 2910-325648-12 Control Unit

TEL Tokyo Electron 2910-325648-12 Control Unit

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

TEL Tokyo Electron 2910-325648-12 Control Unit

Product Details Introduction

TEL Tokyo Electron 2910-325648-12 Control Unit is a critical system control module specifically designed for TEL semiconductor manufacturing equipment. It is mainly responsible for coordinating multiple functional subsystems within the equipment, executing core control logic, and ensuring the accuracy, safety, and stability of the process flow.

1、 Basic Information

Product Name: Control Unit

Product model: 2910-325648-12

Manufacturer: Tokyo Electron Ltd. (TEL)

Category: System level controller or partition control module

Deployment location: Installed in the electrical control cabinet or functional module control area of the equipment

2、 Core functions

Equipment status management

Manage the boot/ready/running/alarm/standby status of devices.

Provide signal coordination and synchronization control for the operation process of the equipment.

Multi subsystem linkage control

Coordinate the operational logic of subsystems such as gas control module (GCU), vacuum system, power management, heating/cooling system, etc.

Implement sequential control and state feedback for complex processes.

Communication and Data Processing

Communicate with the main control system, HMI interface, and remote monitoring system;

Receive control commands from the upper computer, upload operational status and alarm information.

Fault detection and safety interlocking

Real time monitoring of operating parameters, such as sensor status, power status, valve feedback, etc;

Implement safety mechanisms such as emergency stop, alarm, and interlock protection in abnormal situations.

3、 Typical application devices

This control unit may be used in the following TEL devices:

Etch Systems (dry etching): controls processes such as chamber pressure, gas switching, RF power, etc.

CVD/ALD Systems: Coordinate the precise linkage of heating zone, reaction chamber, and chemical source module.

Track Systems: Synchronize the operation of process subunits such as coating, developing, soft drying, and cooling.

Wafer Transfer Systems: Achieve precise synchronous control of robotic arms, conveyors, and clamping mechanisms.

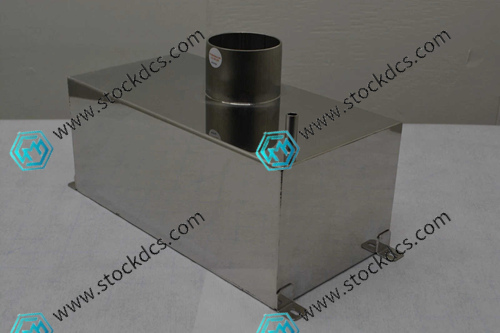

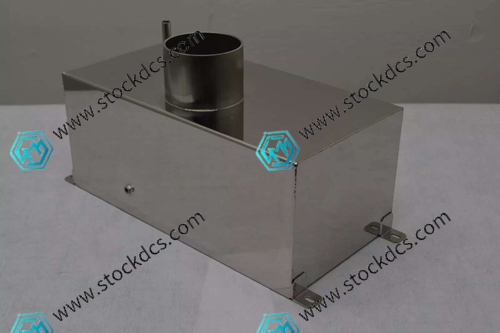

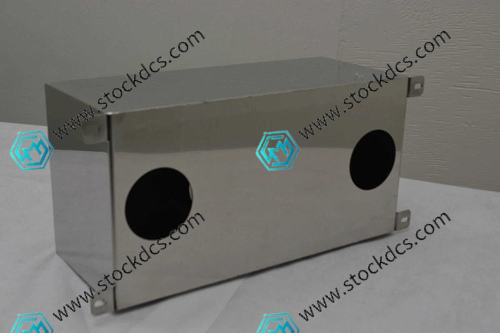

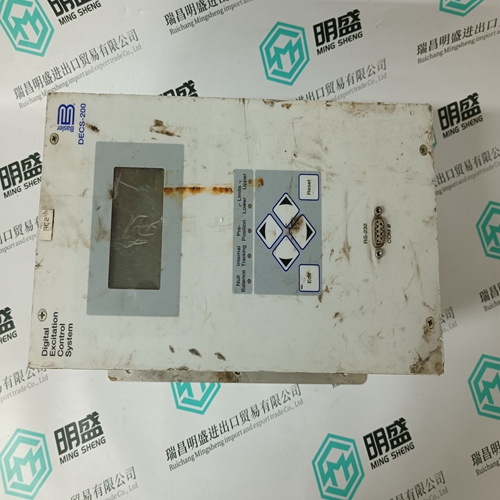

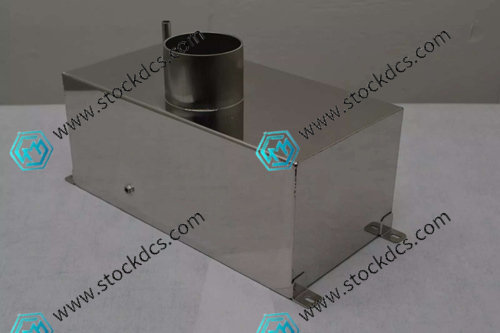

Product imag

Related website links

ASEA DSQC108 controller backplane

FOXBORO RH926GH Control Input Card

Fanuc A06B-6115-H006 servo drive

Other website links

| S32HNNA-RNNM-00 | SC723A-001 | SCE903-001-01 |

| S32HNNA-HGVM-00 | SC726A-001-PM72009 | SCE904-002-01 A |

| S32HMAA-HNNM-03 | SC453-016-02 | SC904AN-046-01 |

| S32GNNA-RNNM-00 | SC453-004-15 | SCE906-001-01 |

| S32GNNA-RNNE-00 | SC453-804-05 | SCE904-001-01 |

| S32GNNA-HGNM-00 | SC452-815-05 | SC9020010104G108 |