Home > Product > DCS control system > KLA Tencor 710-609995-002 Controller

KLA Tencor 710-609995-002 Controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:710-609995-002

- Get the latest price:Click to consult

KLA Tencor 710-609995-002 Controller

Product Details Introduction

KLA Tencor 710-609995-002 Controller - Product Application Fields

This controller is a key module in KLA Tencor's high-end semiconductor detection and measurement equipment, typically responsible for system level control, motion coordination, motor drive, or equipment functional logic management. According to KLA's equipment architecture and naming convention, the 710-609995-002 controller has the following typical applications:

1. System control unit for wafer inspection and measurement equipment

Applied to KLA systems such as Surfscan, P-Series, SP series, eBeam, etc;

As the main control unit, coordinate the collaborative work of multiple sub modules (image acquisition, focusing, handling, laser scanning, etc.) within the device;

Execute real-time operating system (RTOS) or embedded logic control tasks to ensure detection accuracy and response speed.

2. Motor and servo control of multi axis motion platform

Control the movement of X/Y/Z or R axis platforms, supporting sub micron positioning;

Integrate or match stepper motors, linear motors, or servo systems to perform operations such as autofocus and wafer handling;

Support closed-loop feedback systems (such as encoders) to improve motion accuracy and reliability.

3. Synchronization and control of optical and imaging modules

Manage signal coordination between laser emitters, image capture devices (CCD/CMOS), and processors;

Adjust scanning frequency, exposure time, and optical path alignment to optimize defect recognition image quality.

4. System communication and equipment coordination core

Communicate with the main system through various industrial communication interfaces such as RS-232/422, CAN, EtherCAT, PCIe, LVDS;

Implement data exchange and state synchronization between submodules;

As an intermediate control layer that bridges the main control board and various execution units in complex systems.

Applicable industries and system scenarios

Application direction scenario description

Key modules such as optical scanning, image acquisition, and wafer positioning system for wafer inspection control

Measurement equipment drives multi axis platforms, focusing devices, and high-precision detectors

Automated manufacturing serves as the core of equipment control logic processing, scheduling and coordinating various functional modules

Laser and optical measurement system control laser path adjustment, focusing system, scanning head and image sensor work synchronously

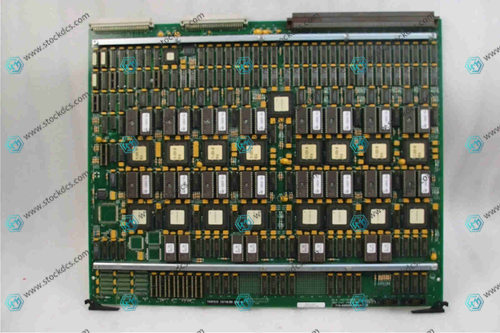

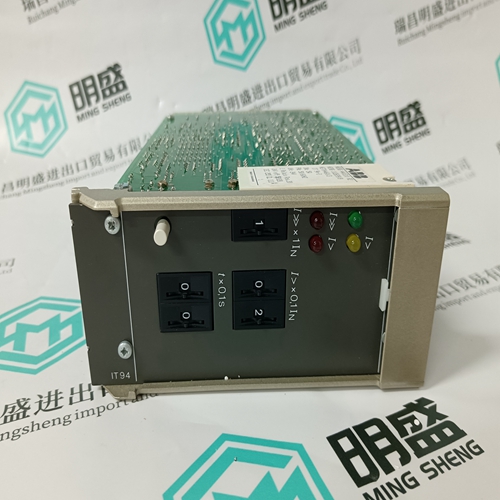

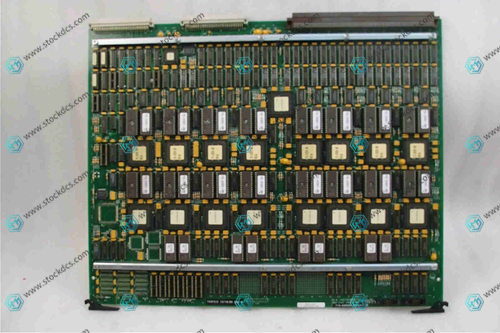

Product imag

Related website links

AMAT 0190-24282 encoder module

AMAT 0190-11415 Digital Input Module

GE D20 EME 10BASE-T Digital Control Modu

Other website links

| PC843-001-F | AMAT 0100-09031 | 57310001-KY DSCL110A ABB |

| PC843-001-A | AMAT 0100-20032 | HESG447427R0001 70EI05A-E |

| PC842-XYZ-T | AMAT 0100-00720 | 57330001-Y DSBB110A ABB |

| PC842-XYZ-N | AMAT 0100-90704 | NFTP01 |

| PC842-XYZ-F | AMAT 0100-09027 | HESG332194R0001 70BK06A-E |

| PC842-XYZ-A | AMAT 0100-03108 | HESG447440R0003 RS422/485 70BK03C-E |

| PC842-001-T | AMAT 0100-09114 | 57510001-AA DSCA114 ABB RS232C |

| PC842-001-N | AMAT 0100-00347 | 57350001-CU DSAV111 ABB |