Home > Product > Servo control system > KLA Tencor 712-404056-00 Interface Board

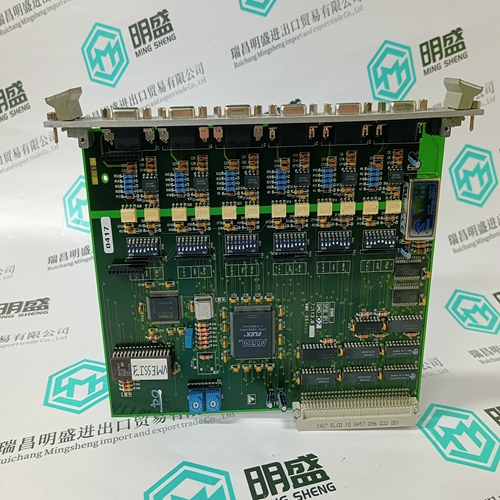

KLA Tencor 712-404056-00 Interface Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:712-404056-00

- Get the latest price:Click to consult

KLA Tencor 712-404056-00 Interface Board

Product Details Introduction

KLA Tencor 712-404056-00 Interface Board Product Application Fields Detailed Explanation

Stacked alignment detection system

Mainly used for KLA Tencor's 5100 and 5200 series equipment, which focus on precise alignment of multi-layer patterns on wafers.

The interface board is responsible for receiving and distributing signals from various detection modules, ensuring the alignment accuracy of upper and lower layer patterns at the nanometer level, and is a key hardware for achieving high-precision pattern detection.

Signal Management and Communication Bridge

As a signal bridge between internal modules of the device, the interface board coordinates multiple signals from sensors, actuators, and processors.

Ensure the stability and low latency of data transmission, support real-time data feedback and high-speed communication, and meet the requirements of high-frequency detection.

System control and automation process support

Support automated detection processes for devices, enabling automatic scheduling and control of complex detection tasks.

Through stable signal transmission, precise control of hardware such as robotic arms and scanners is achieved, ensuring smooth detection processes and reliable results.

Equipment maintenance and quick replacement

Modular design facilitates rapid on-site maintenance and replacement of equipment, reducing downtime.

Support remote diagnosis function to help engineers quickly locate faults and improve maintenance efficiency.

System upgrade and compatibility expansion

Support system software and hardware upgrades, the interface board provides multiple interfaces to adapt to new detection modules and sensors.

Helps to extend the lifecycle of equipment and meet the continuous progress and changing demands of semiconductor manufacturing processes.

Semiconductor manufacturing production line integration

As an important component of wafer inspection and measurement equipment, interface boards assist in the automation of production lines, achieving digitalization and intelligence of production line monitoring.

Improve the integration and stability of detection equipment, support high-speed operation of production lines, and enhance overall manufacturing efficiency and yield.

Environmental and reliability requirements

The design meets strict standards for semiconductor manufacturing environments and can adapt to temperature and humidity changes as well as electromagnetic interference in cleanroom environments.

High reliability and stability ensure long-term continuous operation, reducing the risk of production interruption.

Product imag

Related website links

A-B 1794-IRT8XT Relay Output Module

ABB XXD129A01 Card Module Controller

Other website links

| S32GNNA-HGNM-00 | SC322A-001 | S21HNNA-RNNE-00 |

| S32GNAA-RNVE-00 | SC323A-001 | SC104-001-T3 |

| S32GMNA-RNNM-00 | SC402-010 | SC105010I3 |

| S31HSNA-RNNM-03 | SC403-002-T3 | SC104-001-M |

| S31HNNA-RNNM-00 | SC322A-601-01 | SC105-001-M |

| S31HMAA-RNEE-00 | SC402-001-T3 | SC103-010-T4 |

| S31ANNH-RNNM-00 | SC102-010-T4 | S21GSAA-RNNM-02 |

| S24HSNA-RNNM-02 | SC403-001-T4 | SC104-001 |